Thermoplastic composite core material and equipment comprising same

A composite core and thermoplastic technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, sheets/boards, etc., can solve the distribution characteristics of the limited and addable proportion dispersion of functional materials, limited functional effects, functional Diversified demand bottlenecks and other issues, to achieve the effects of significant functional effects, good compatibility, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

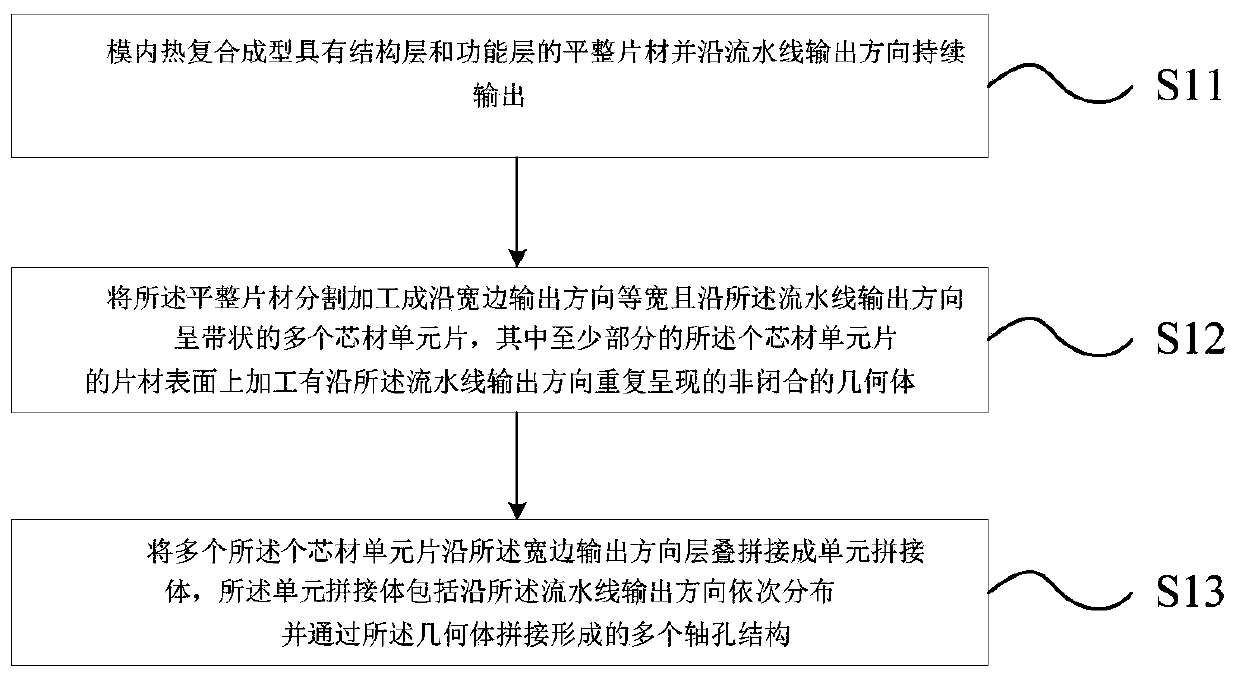

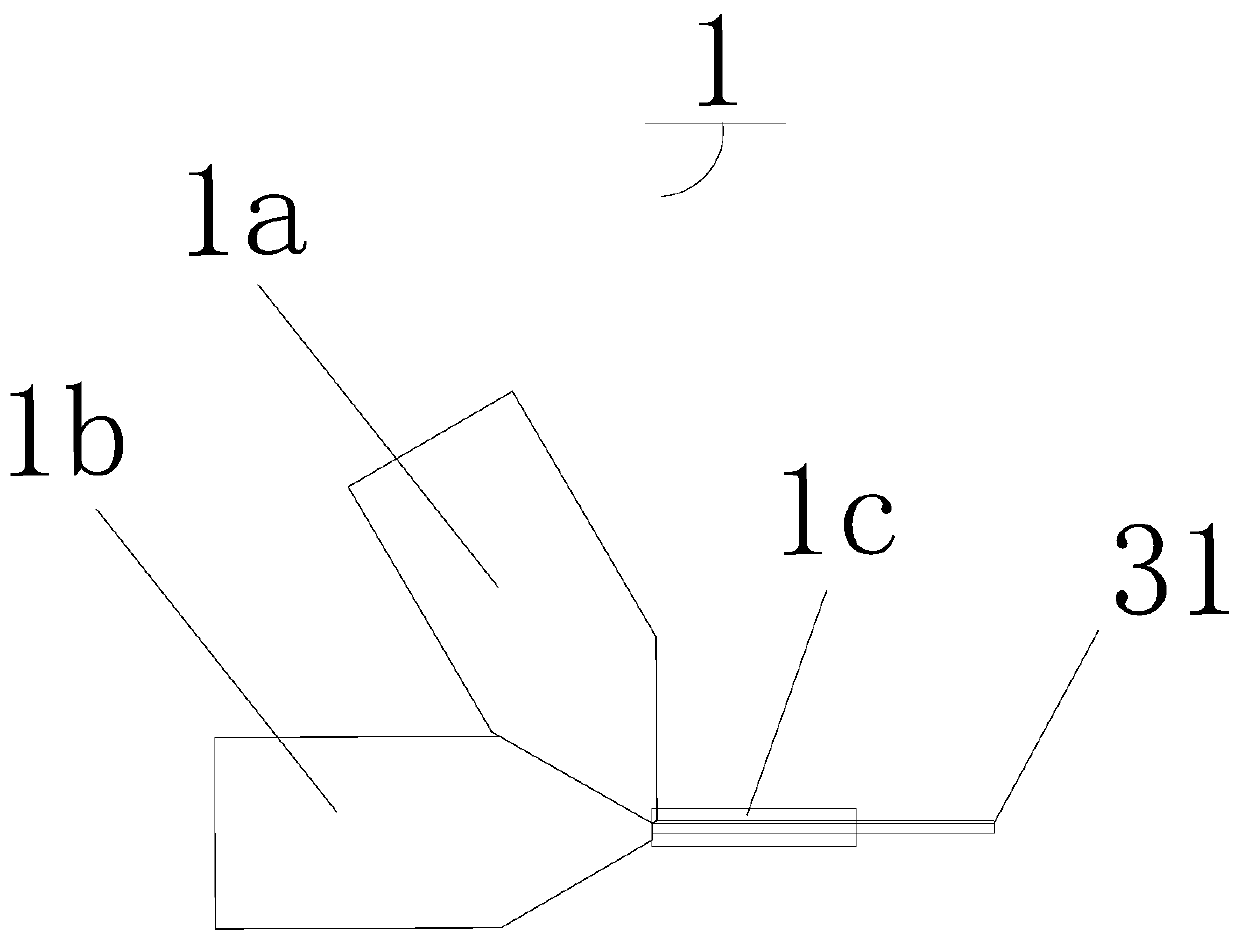

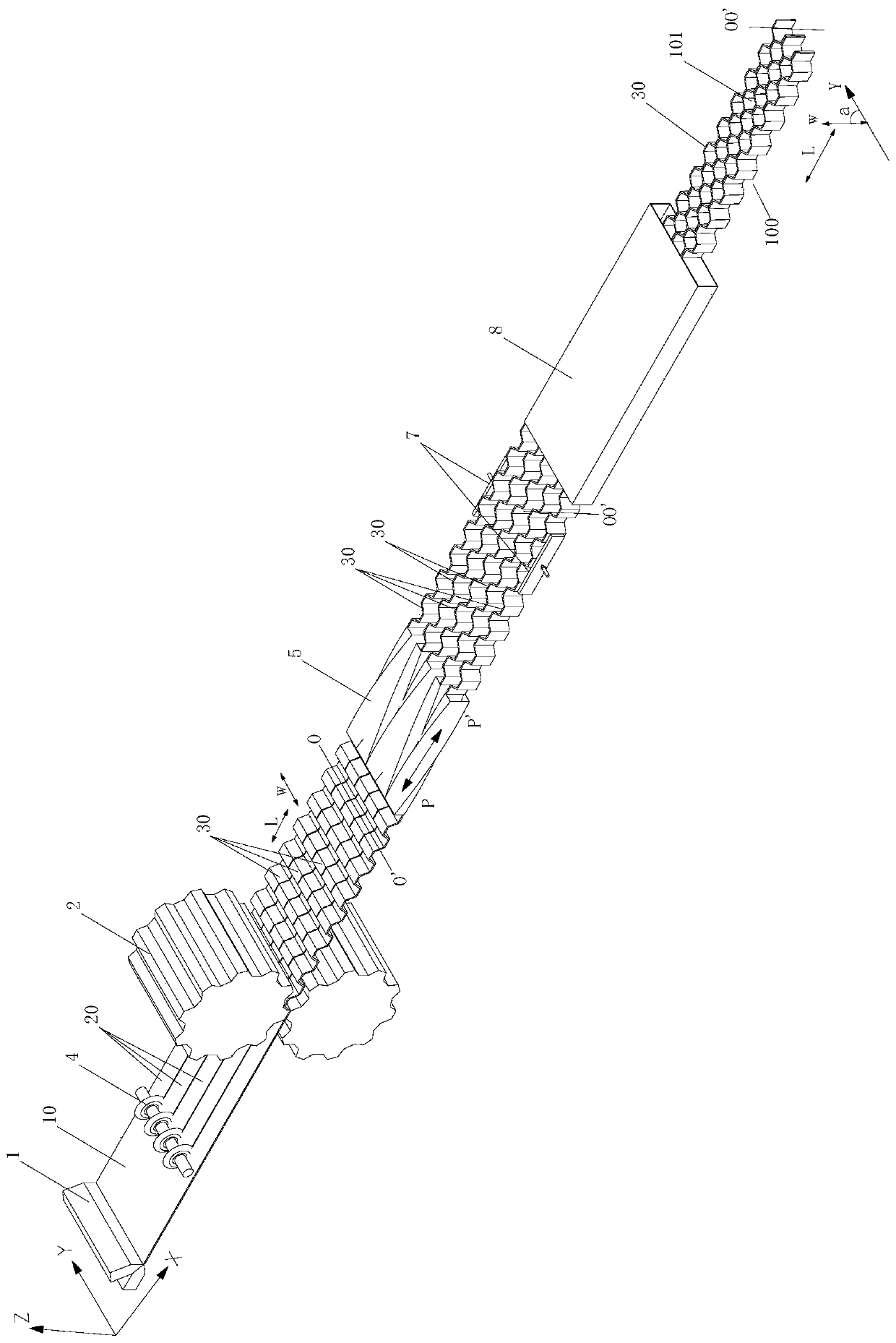

[0064] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

[0065] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0066] In the embodiments of the present invention, unless stated to the contrary, the used orientation words such as "up, down, top, bottom" usually refer to the directions shown in the drawings or refer to vertical, vertical or The term used to describe the mutual positional relationship of each component in terms of the direction of gravity.

[0067] The present invention will be described in detail below in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com