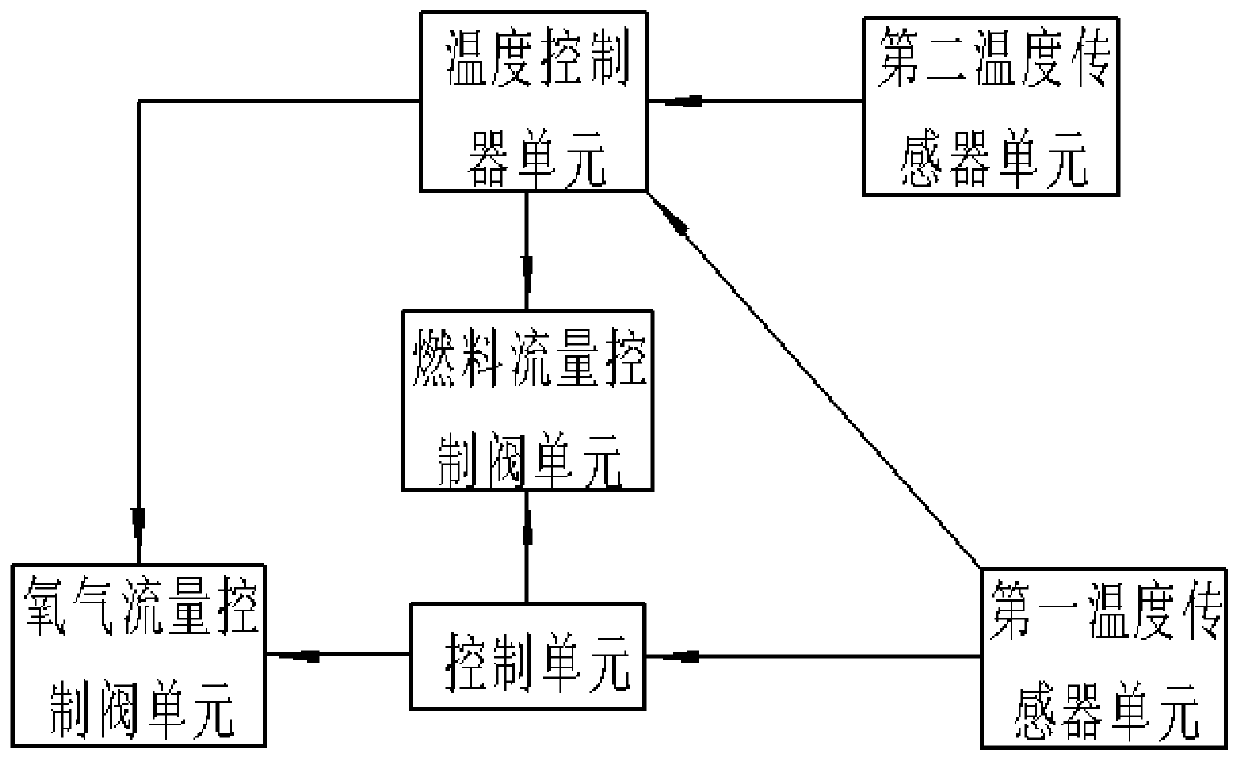

Full-automatic cleaning method of pure oxygen combustor and cleaning control device of pure oxygen combustor

A cleaning method and burner technology, which is applied in the direction of furnace control devices, descaling devices, furnaces, etc., can solve problems such as damage to burner nozzles, difficult temperature control, damage to furnace refractory materials, etc., to achieve easy operation and automatic cleaning , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solution of the present invention will be clearly and completely described below.

[0048] In order to solve the above problems, the present invention provides a fully automatic cleaning method for a pure oxygen burner and a cleaning control device thereof. Easy control adjustments allow for a hassle-free changeover between use and cleaning during production.

[0049] In order to achieve the technical purpose, the technical solution of the present invention is: a fully automatic cleaning method for a pure oxygen burner and its cleaning control device, which is characterized in that it includes the following steps:

[0050] S1: Start and ignite the controller;

[0051] S2: After successful ignition according to the controller in step S1, control the kiln to reach the production temperature according to the heating curve. The controller starts the high temperature mode;

[0052] S3: After the high temperature mode is turned on according to step S2, set ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com