Ferro magnetic material irregular crack ACFM visual imaging method

A technology of ferromagnetic materials and imaging methods, applied in the direction of material magnetic variables, etc., can solve the problems of complex electromagnetic field distortion, inability to visually display the surface contour of irregular cracks, and inability to realize imaging display of irregular cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

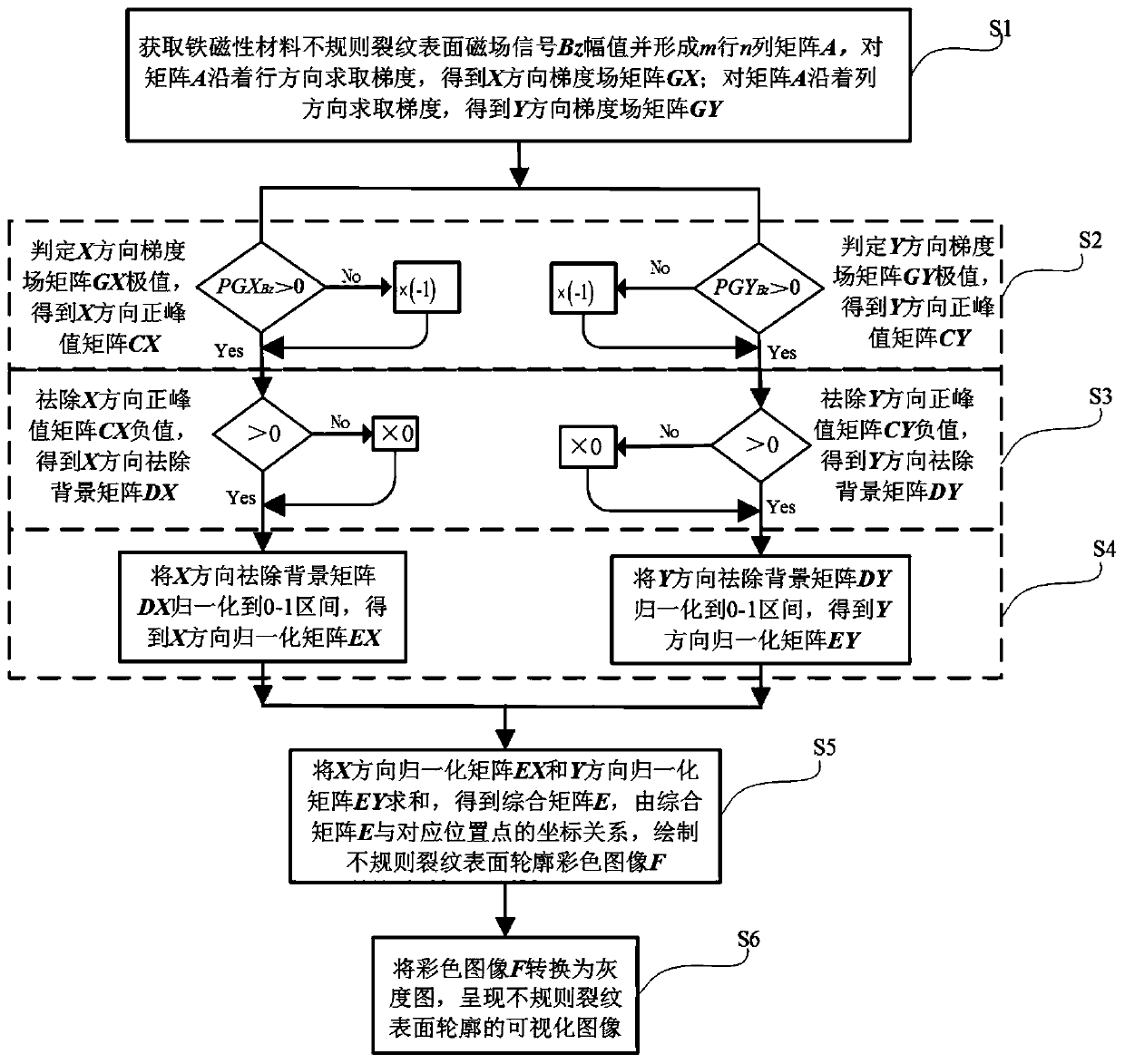

[0029] figure 1 The flow chart of the ACFM visual imaging method for irregular cracks in ferromagnetic materials provided by the embodiment of the present invention includes:

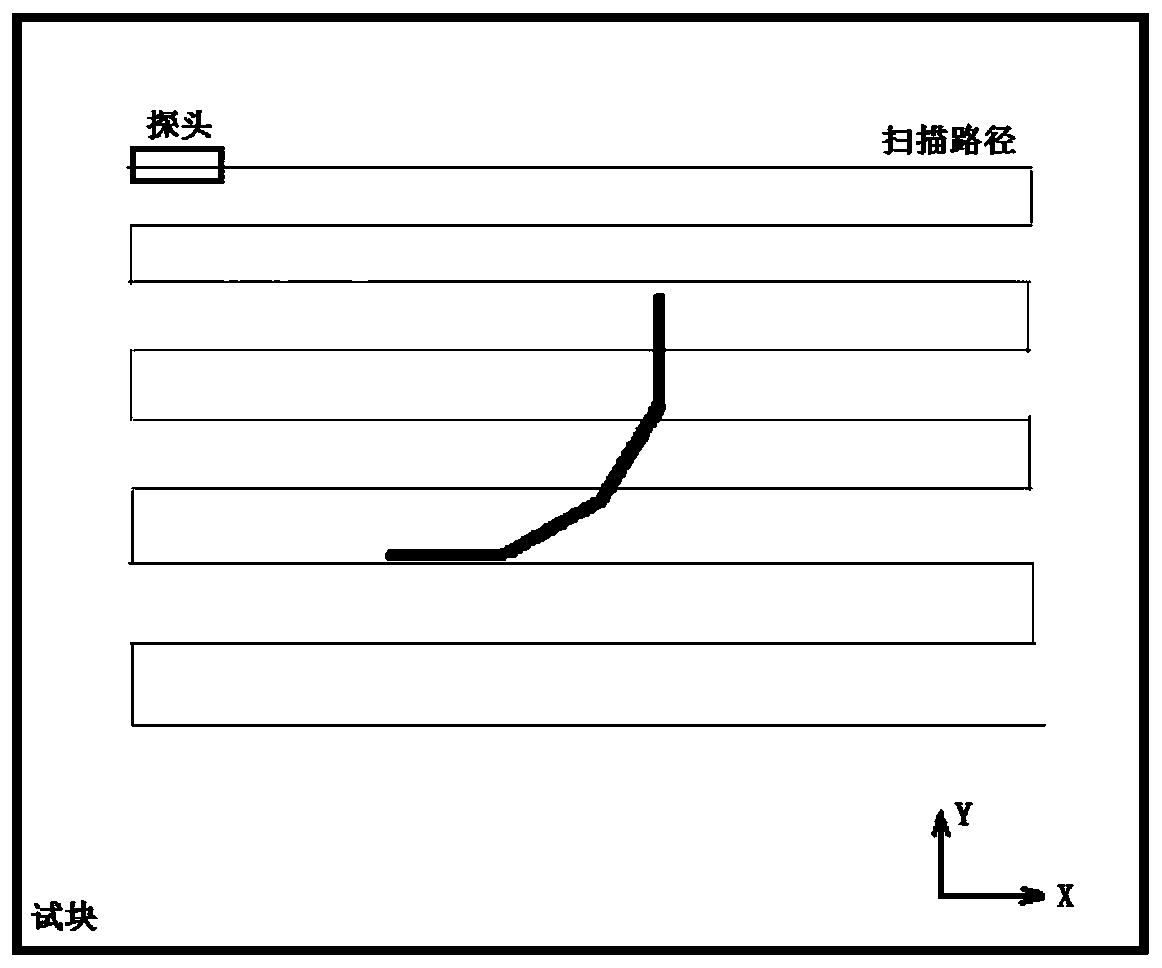

[0030] S1. Prepare a carbon steel test block. There are irregular cracks on the surface of the test block. The irregular cracks are composed of four cracks at 0°, 30°, 60° and 90°. The crack depth is 2.0mm and the width is 0.8mm. figure 2 shown. The schematic diagram of the probe grid scanning path is as follows: image 3 As shown, the scanning direction of the probe is defined as the X direction. Using the grid scanning method, the AC electromagnetic field detection probe is used to detect the 89.0mm×88.0mm area along the scanning path at the same height plane on the surface of the irregular crack of the test block, and the X direction scans The search step length is 1.0mm, the number of equidistant position points on the scanning path in the X direction is 90, the spacing of the scanning path in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com