Corrosion defects Visual imaging and evaluating method based on alternating current electromagnetic fields

A technology of alternating electromagnetic fields and defects, applied in the direction of material magnetic variables, etc., can solve the problems of complex surface contour and three-dimensional shape, difficult surface contour imaging and evaluation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

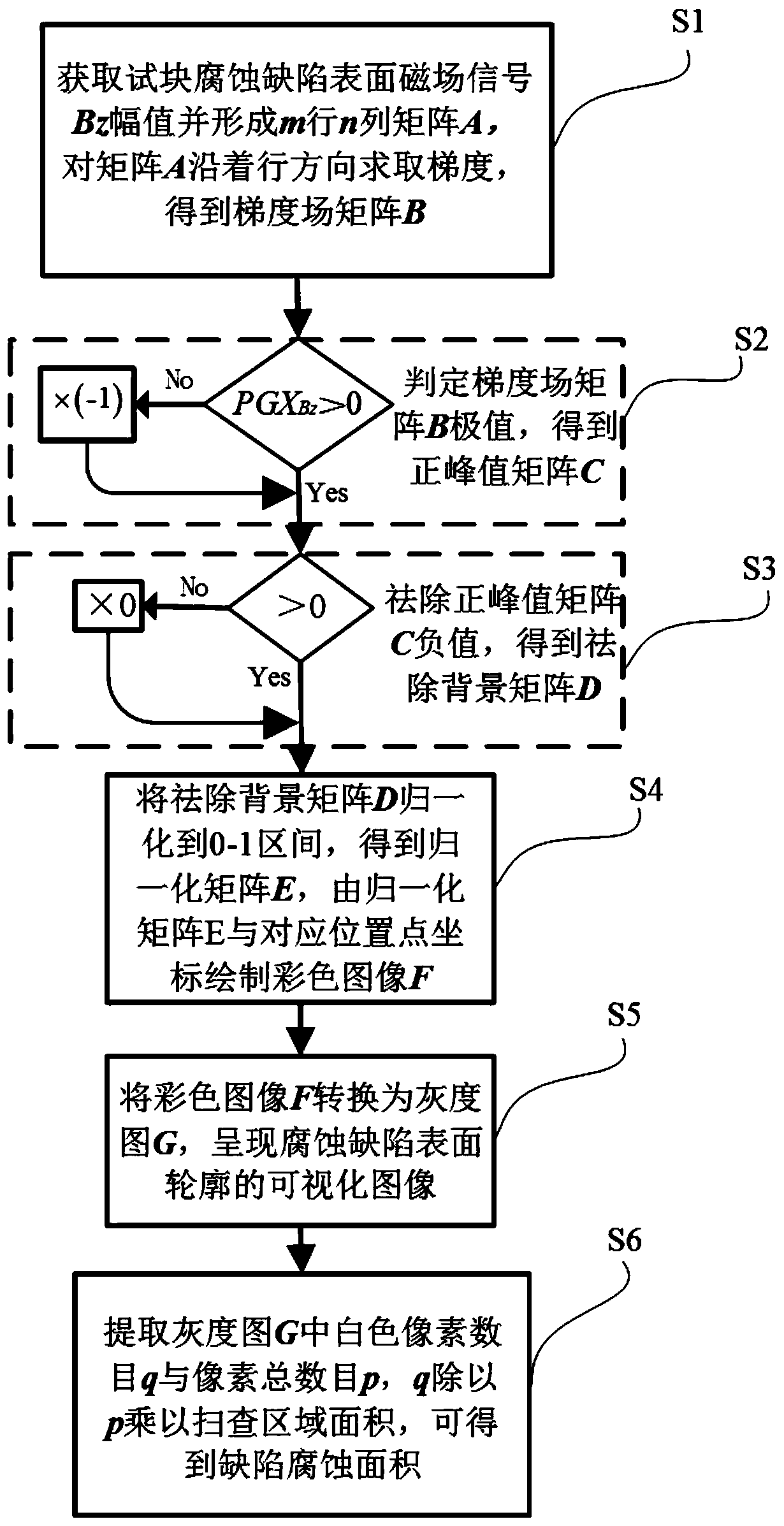

[0026] figure 1 The flow chart of the visual imaging and evaluation method of corrosion defects based on AC electromagnetic field detection technology provided by the embodiment of the present invention includes:

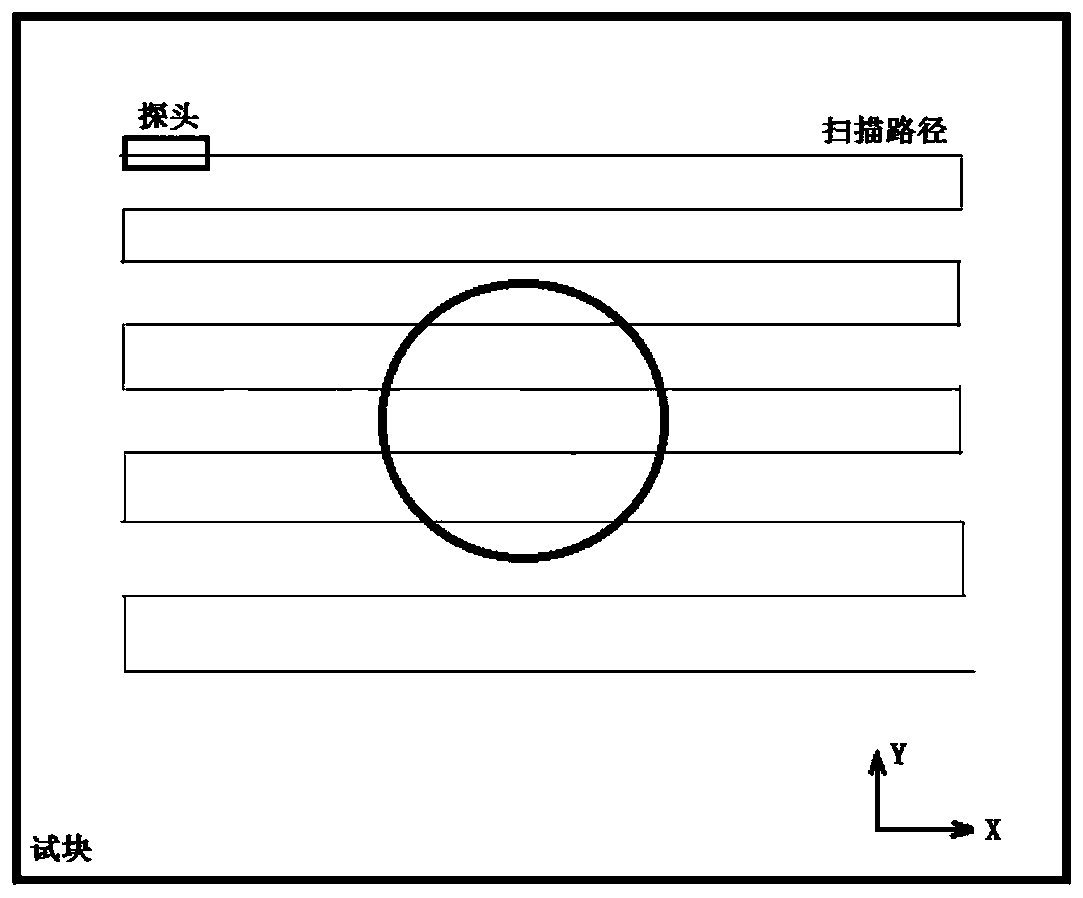

[0027] S1, prepare a carbon steel test block, with corrosion defects on the surface of the test block, such as figure 2 As shown, the diameter of the corrosion defect is 10.0mm, and the depth is 0.5mm. Define the probe scanning direction as the X direction, adopt the grid scanning method, and use the AC electromagnetic field detection probe to detect 40×40mm along the scanning path at the same height plane on the surface of the corrosion defect of the test block 2 area, such as image 3 shown. The scan step length in the X direction is 0.5mm, the number of equally spaced points on the scan path in the X direction is 80, the distance between the scan paths in the Y direction is 1.0mm, and the number of equally spaced scan paths in the Y direction is 40, to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com