Ultrasonic TOFD dead zone inhibition method based on synthetic aperture focusing and mode converted wave

A technology of synthetic aperture focusing and mode conversion, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and the processing of detection response signals to improve quantitative accuracy of defects, suppress TOFD blind spots, The effect of improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

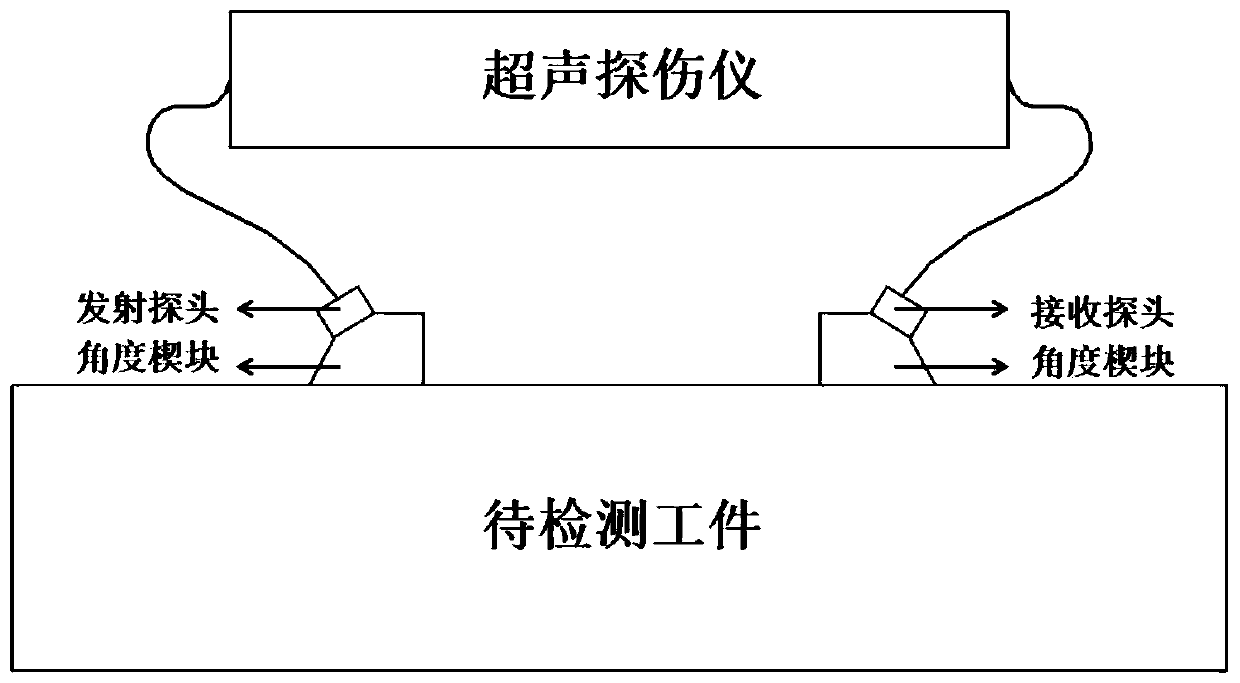

[0034] Ultrasonic TOFD blind area suppression method based on synthetic aperture focusing and mode conversion wave, the ultrasonic detection system used is such as figure 1 As shown, it includes an ultrasonic flaw detector, a pair of TOFD probes, a pair of longitudinal wave angle wedges and a scanning device. The specific detection and processing steps are as follows:

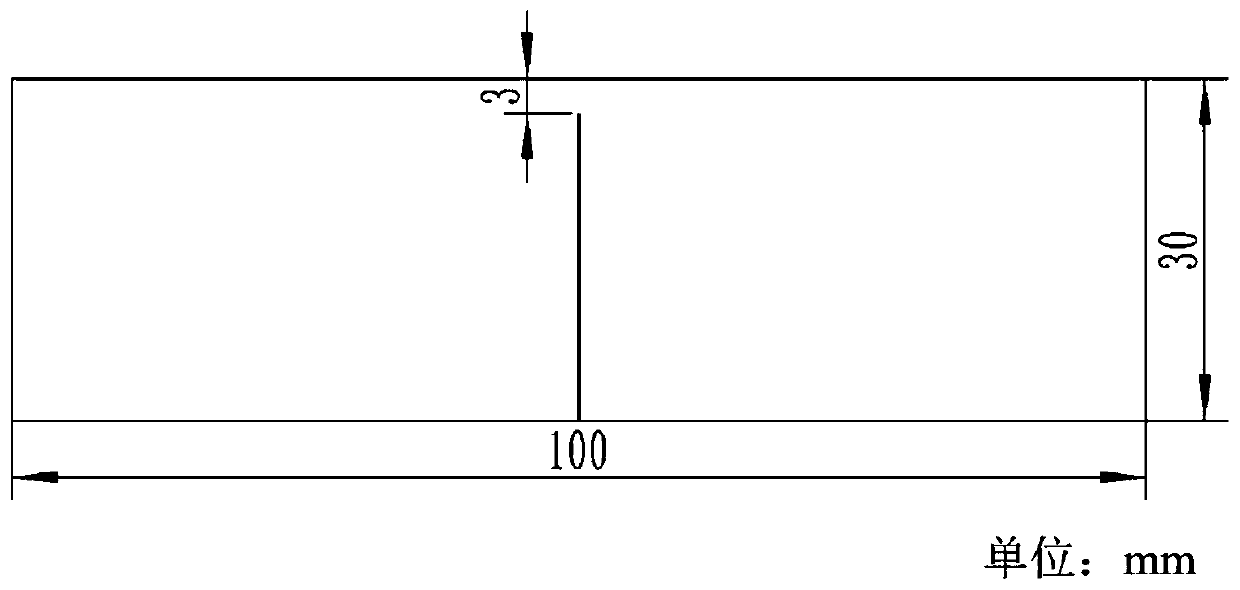

[0035] (a) Test subjects such as figure 2 The carbon steel plate test block shown has a wall thickness of 30.0mm, a longitudinal wave sound velocity of 5890m / s, and a transverse wave sound velocity of 3230m / s. The inside of the test block is processed with an open groove on the bottom surface 3.0mm away from the surface.

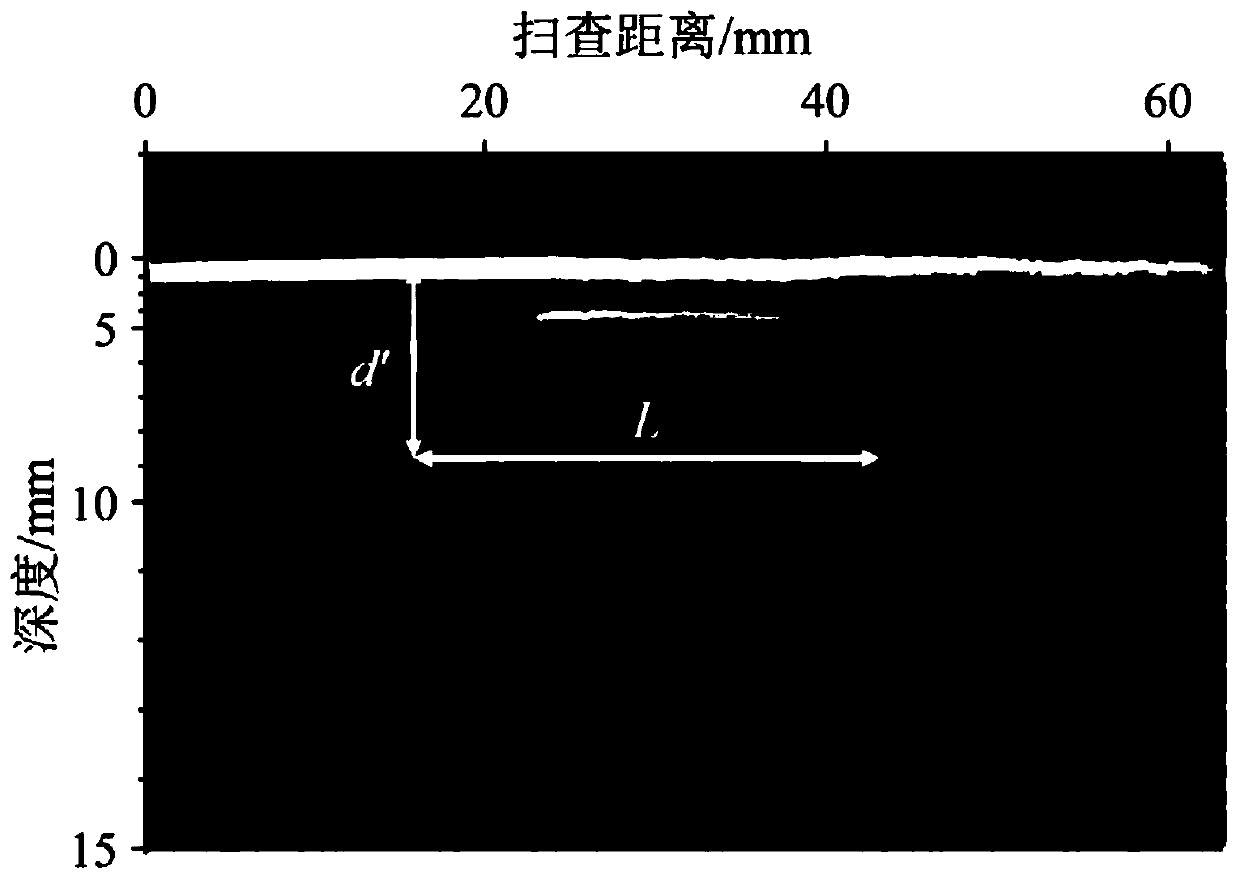

[0036] (b) The TOFD probe with a nominal frequency of 5 MHz is used for detection. The main detection parameters include: longitudinal wave wedge angle 70°, probe center distance 2S = 30.0mm, sampling frequency 100MHz, detection gain 60dB, scanning step ΔS = 0.40mm, A-scan time window star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com