Sintering process working condition identification method and system considering time sequence

A technology for sintering process and working condition recognition, which is applied in character and pattern recognition, instruments, data processing applications, etc. It can solve the problems of not considering the timing correlation between data and the reliability of working condition recognition results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

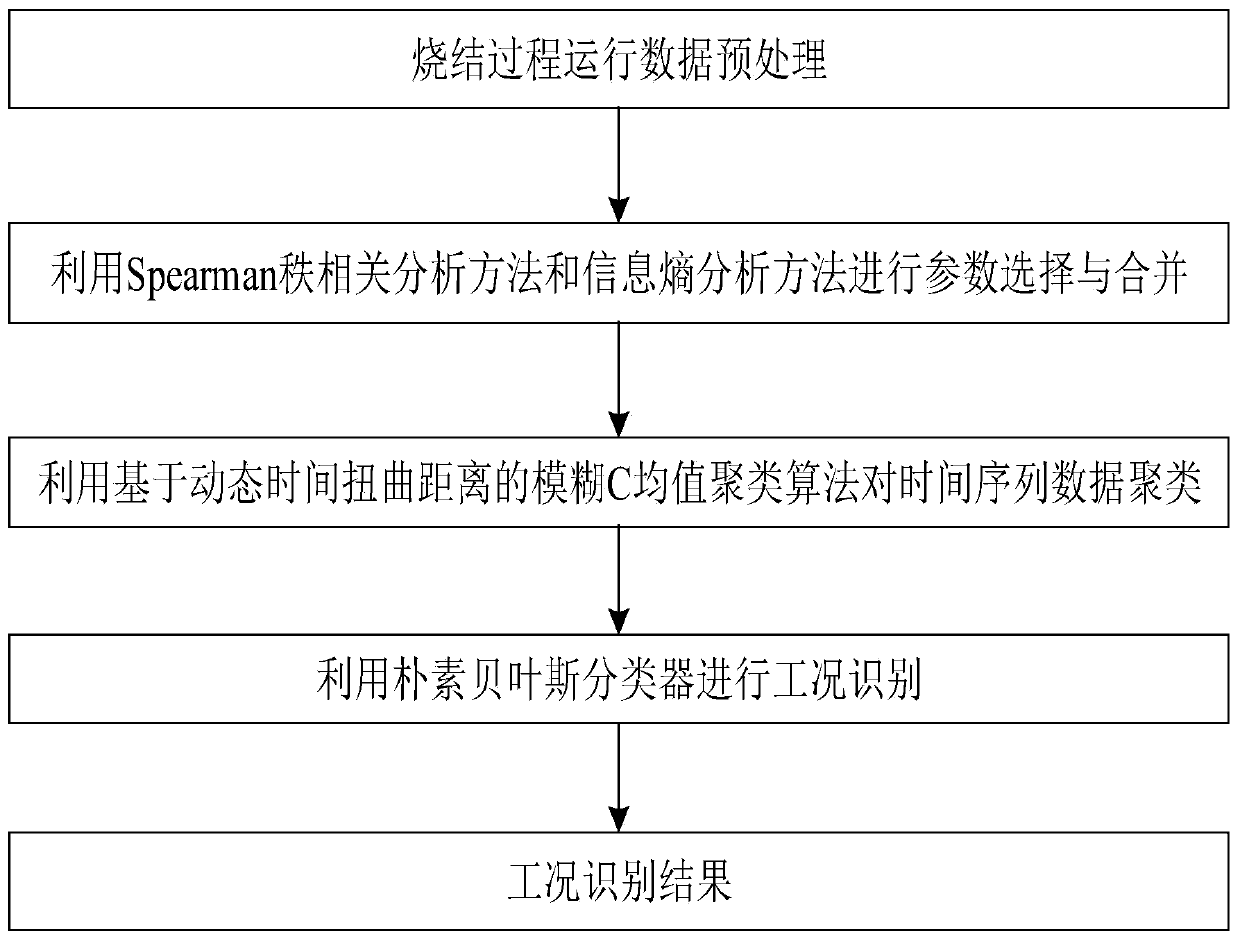

[0053] A sintering process working condition identification method considering timing, such as figure 1 shown, including:

[0054] Step 1: Obtain the detection parameters of the sintering process from the sensor of the sintering machine, and perform data preprocessing on the detection parameters of the sintering process, specifically including:

[0055] Use the median filter to process the detection parameters of the sintering process to reduce the random error of detection; eliminate the zero detection data caused by sensor failure and shutdown; set the sampling interval of data to 30 seconds to reduce the redundancy of data; select each time The length of the subsequence is 5 minutes and contains 10 data points for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com