Printed circuit board, manufacturing method thereof, and method for printing mark thereon

A technology for printed circuit boards and manufacturing methods, which are applied in printed circuit components, circuit inspection/recognition, conductive pattern formation, etc., can solve problems such as unclear marks, oily marks, and surfaces that are easily rubbed and bumped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

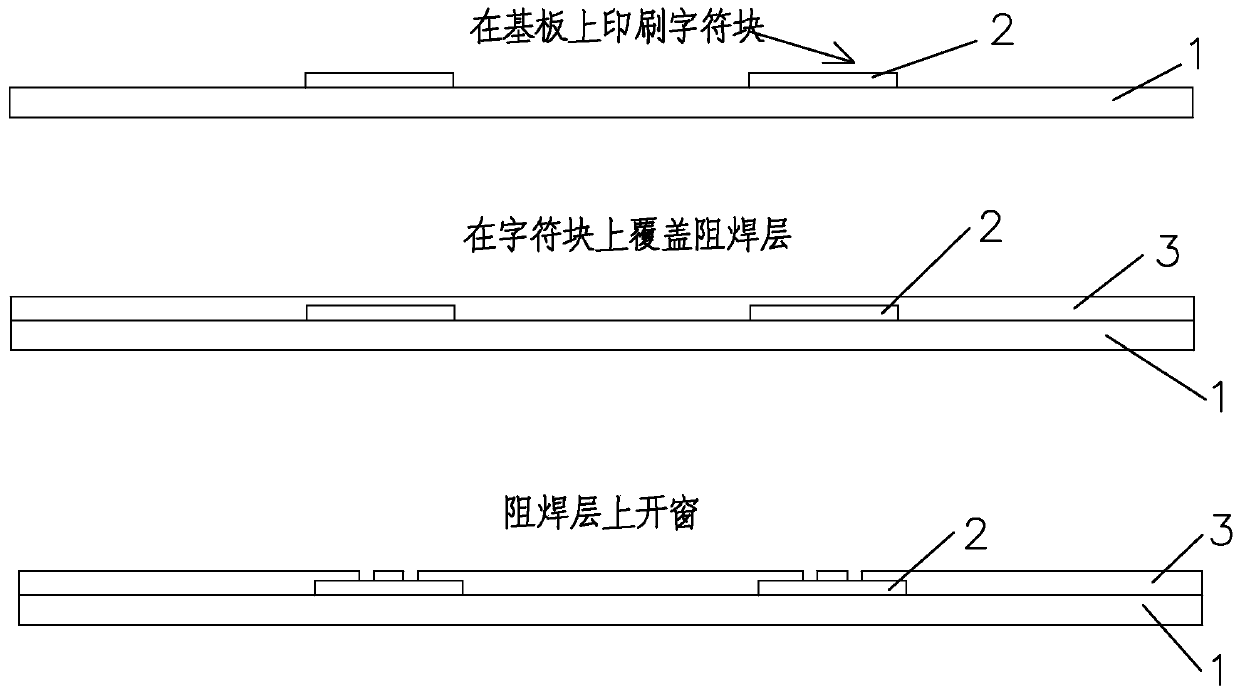

[0028] A method for printing a mark on a printed circuit board, comprising the following steps:

[0029] Step 1) Select the substrate 1 as a glass fiber substrate, and silk-screen character blocks 2 on the glass fiber substrate. The character blocks 2 are solid and non-transparent in color, and the character blocks 2 are larger than the outline of the above-mentioned logo. In this embodiment, a glass fiber substrate is used. The glass fiber substrate uses epoxy resin as an adhesive and glass fiber cloth as a reinforcing material; the glass fiber substrate can adapt to a higher working temperature and is less affected by the environment, so silk screen The character block 2 above it can have more ink options, and both photosensitive ink and UV ink can be used. The color of the character block 2 is not limited. In this implementation, as one of the preferred options, black photosensitive ink is selected. The photosensitive ink has the advantages of easy acquisition and economic ...

Embodiment 2

[0033] A method for printing a mark on a printed circuit board, comprising the following steps:

[0034] Step 1) In this embodiment, the substrate 1 is selected as a paper substrate, and the character block 2 is silk-screened on the paper substrate. The character block 2 is a solid non-transparent black block, and the character block 2 is larger than the outline of the above-mentioned logo. In this embodiment Among them, the character block 2 is designed to be 0.5mm larger than one side of the logo. The characters use black UV ink, and the curing process adopts UV curing, and the UV energy is 1600-2200mj.

[0035] In this embodiment, a paper substrate is used. The paper substrate has the characteristics of being capable of punching, low cost, low price, and low relative density. For example, in this embodiment, an easily available FR-2 paper substrate is used.

[0036] Step 2) On the character block 2 made of cured black UV ink, apply white UV solder resist as the solder resi...

Embodiment 3

[0039] A method for printing a mark on a printed circuit board, comprising the following steps:

[0040] Step 1) select the substrate 1 as a paper substrate, and screen-print a character block 2 on the paper substrate. The character block 2 is a solid non-transparent black block, and the character block 2 is larger than the outline of the above-mentioned logo. In this embodiment, the character block 2 The design is 0.5mm larger than the one side of the logo. The character block 2 is screen-printed with black UV ink, and the curing process adopts UV curing, and the UV energy is 1600-2200mj.

[0041] In this embodiment, a paper substrate is used. The paper substrate has the characteristics of being capable of punching, low cost, low price, and low relative density. For example, in this embodiment, an easily available FR-2 paper substrate is used.

[0042] Step 2) Apply white solder resist photosensitive oil on the black character block 2 made of cured black UV ink as the solder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com