Second-generation nuclear power station spent fuel storage cadmium rack disassembly equipment

A technology for dismantling equipment and spent fuel, which is applied in the field of spent fuel processing equipment and can solve problems such as dismantling of dismantling equipment without a cadmium grid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

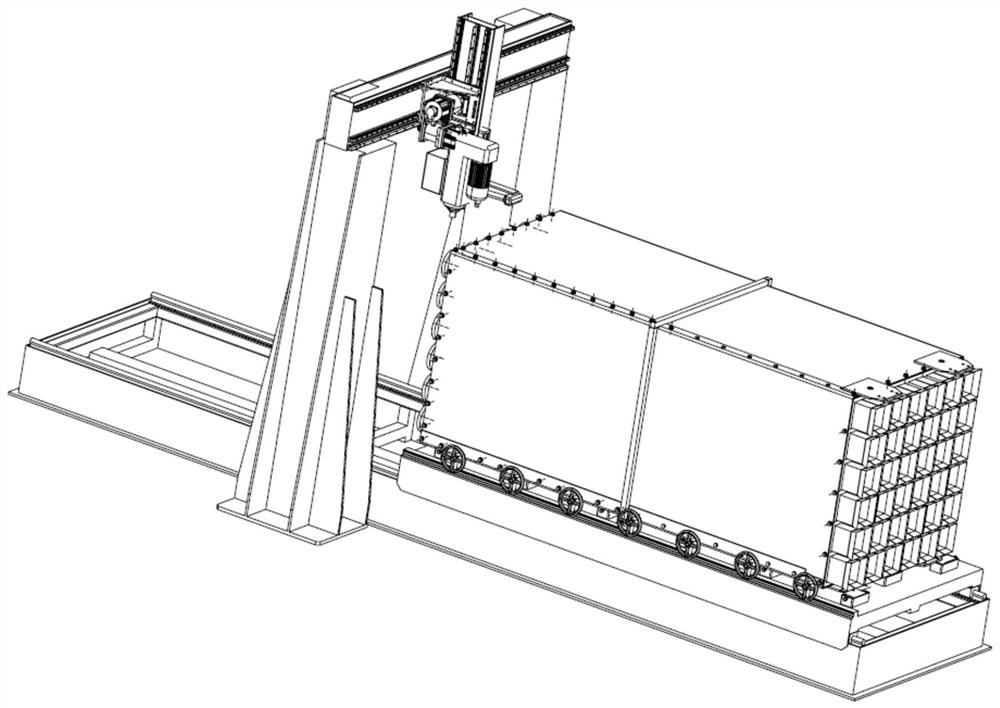

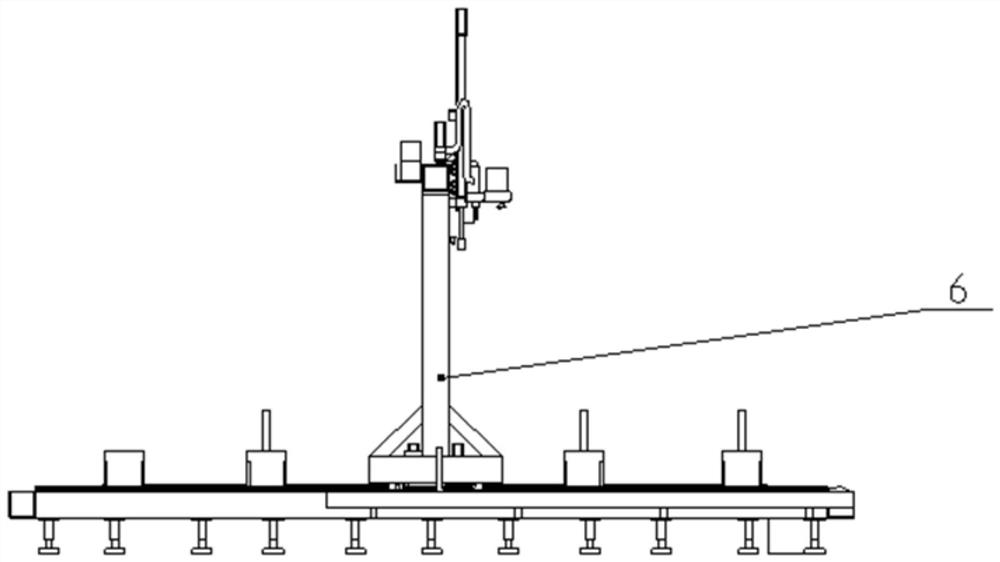

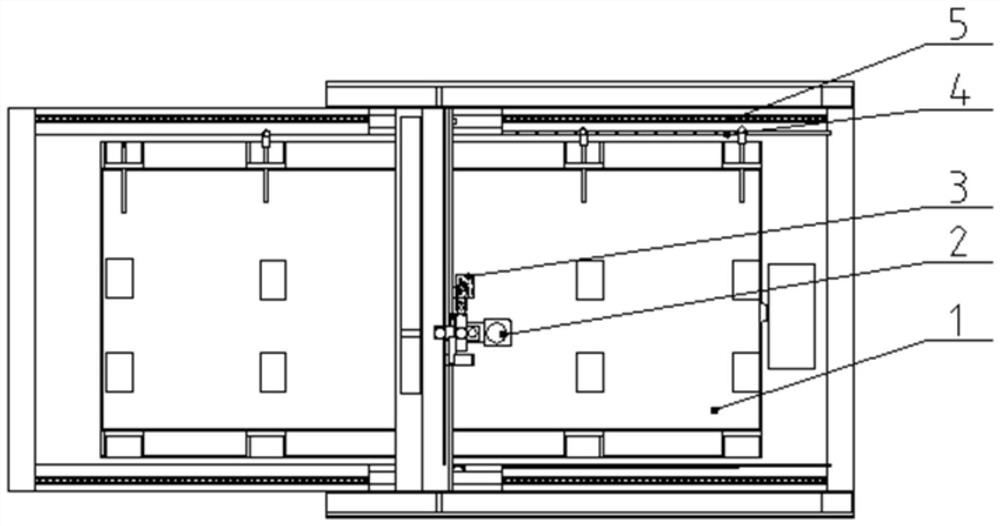

[0035] like Figure 1 to Figure 3 As shown, the dismantling equipment for the spent fuel storage cadmium grid of the second-generation nuclear power plant includes a support platform 1 for supporting the cadmium grid and dismantling parts installed on the support platform 1;

[0036] The disassembled parts include a wrench 3 and a drilling and milling power head 2;

[0037] The drilling and milling power head 2 includes a drill bit and a milling cutter that can work independently;

[0038] The wrench 3, the drill bit and the milling cutter are respectively connected with driving mechanisms for driving their respective work.

[0039] For the dismantling of cadmium grids, in the prior art, since there are no special tools or equipment, the dismantling of cadmium grids is mainly done manually, which leads to the corresponding dismantling personnel being in a radiation environment. It is beneficial to the health of dismantling personnel, and the corresponding protective measures...

Embodiment 2

[0045] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, in order to facilitate the judgment of the bolt seizure situation, to protect the dismantling equipment and to quickly replace the bolt removal method if necessary: switch from loosening the wrench 3 to drilling with the drill bit or using the drill bit to apply torque for bolt removal, It is set to: a detection mechanism for detecting the output torque of the wrench 3 is also included. In specific use, the wrench 3 can be an electric wrench, a pneumatic wrench, a hydraulic wrench, etc. The specific torque detection can be done indirectly by using the detection of the parameters of the wrench drive power supply, the detection of the parameters of the air pressure source, and the detection of the parameters of the hydraulic pressure source. Take advantage of the strain on the wrench for direct access.

[0046] As a technical solution to facilitate automatic work,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com