Lifting control device for planting unit of full-automatic transplanting combined operation machine

A combined operating machine and lifting control technology, which is applied to the lifting device of agricultural machinery, agricultural machinery and implements, agriculture, etc., can solve the problems of difficult maintenance of precision components, high manufacturing and maintenance costs, and low profiling accuracy, so as to avoid The effects of mechanical damage, low manufacturing and use costs, and good copying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to clarify the technical scheme and working principle of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

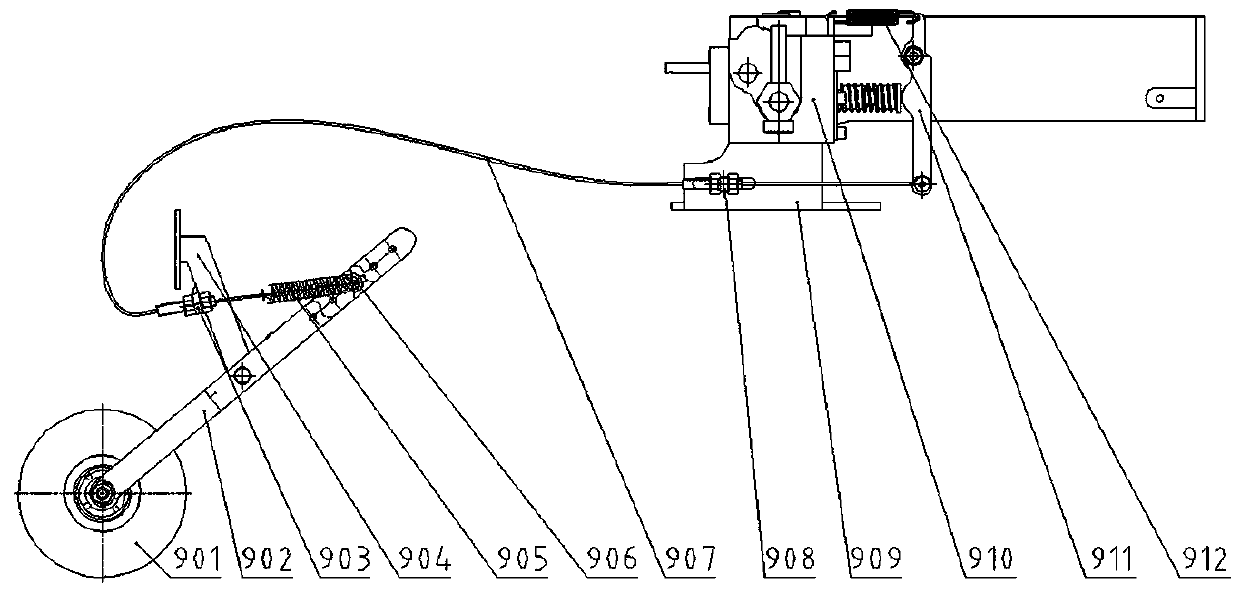

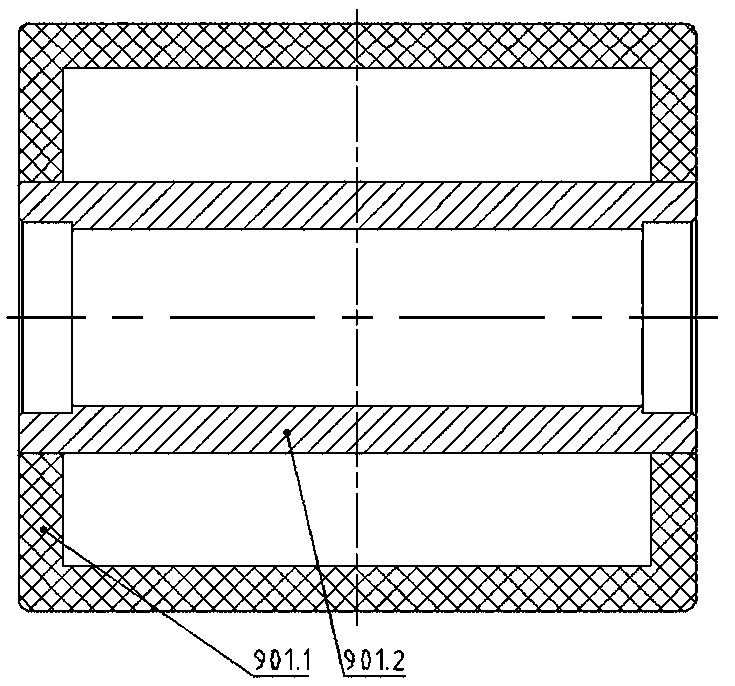

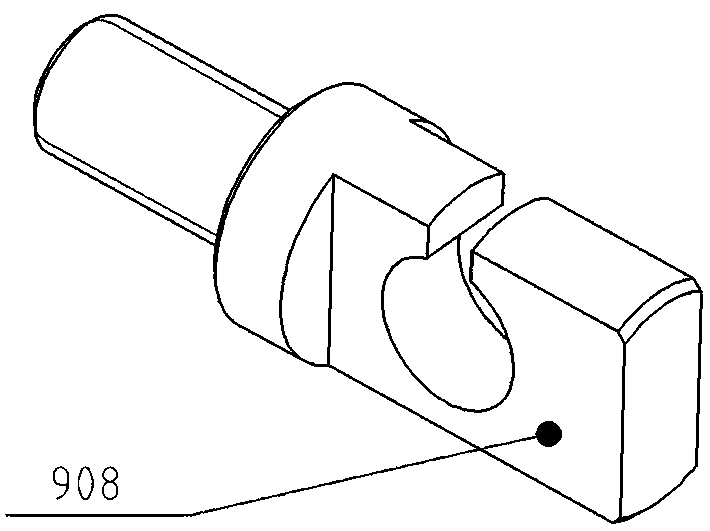

[0042] Such as Figure 8 The combined transplanting operation machine shown includes a tractor, a frame, a hydraulic system installed on the frame, a seedling frame, a rotary tillage and ditching system, a transplanting system, and a soil-covering suppression system. The frame is connected with the tractor through a three-point suspension mechanism, and is driven and pulled by the tractor. The transplanting system is provided with more than one transplanting unit, and each transplanting unit is movably connected with the frame through a pair of independent parallel four-bar profiling mechanism. At the same time, the transplanting system is equipped with a Independently control the lifting oil cylinder 12 of its lifting.

[0043]The lifting of the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com