A dual-inlet adaptive dynamic water and fertilizer mixing device and method

A water and fertilizer mixing and mixing device technology, which is applied in the direction of mixers, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problems of small flow, increase the burden of agricultural production, and limited applicability of the device, and reach the waterway flow rate The effect of maintaining stability and pressure, improving the level of agricultural irrigation management, and reducing the impact of flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

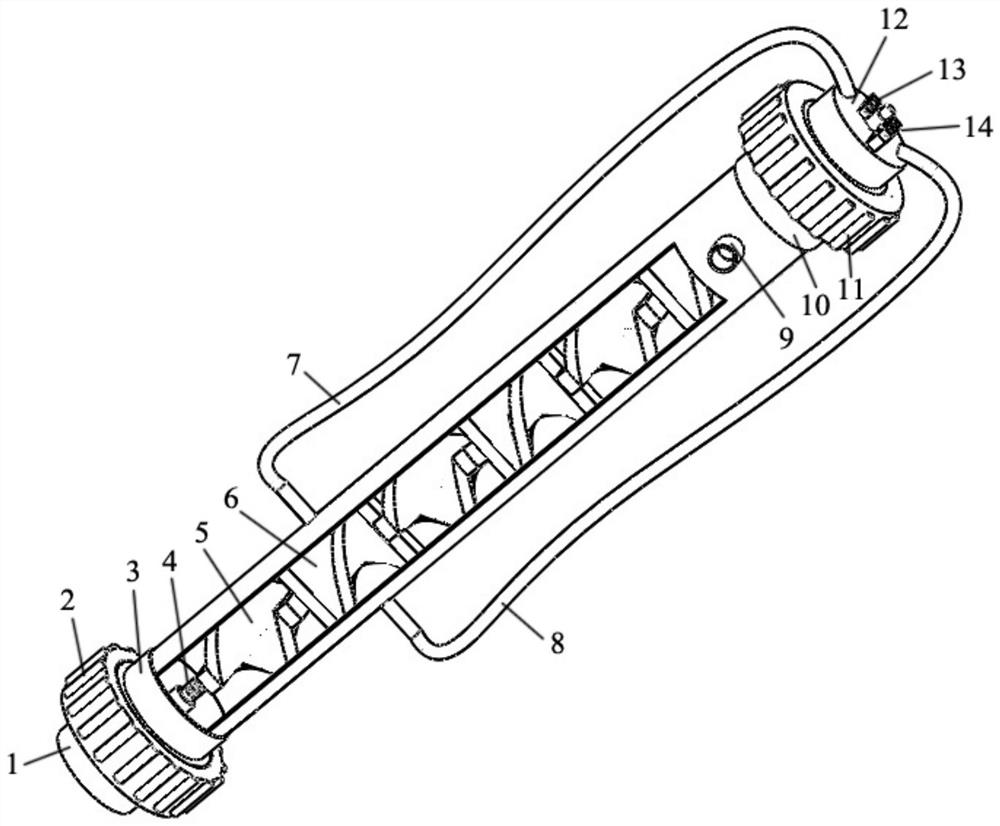

[0065] The present invention is a dual-entrance self-adaptive dynamic water and fertilizer mixing device, such as Figure 1-23 As shown, including mixing blades, blade mounting mechanism, adaptive adjustment mechanism and device bracket;

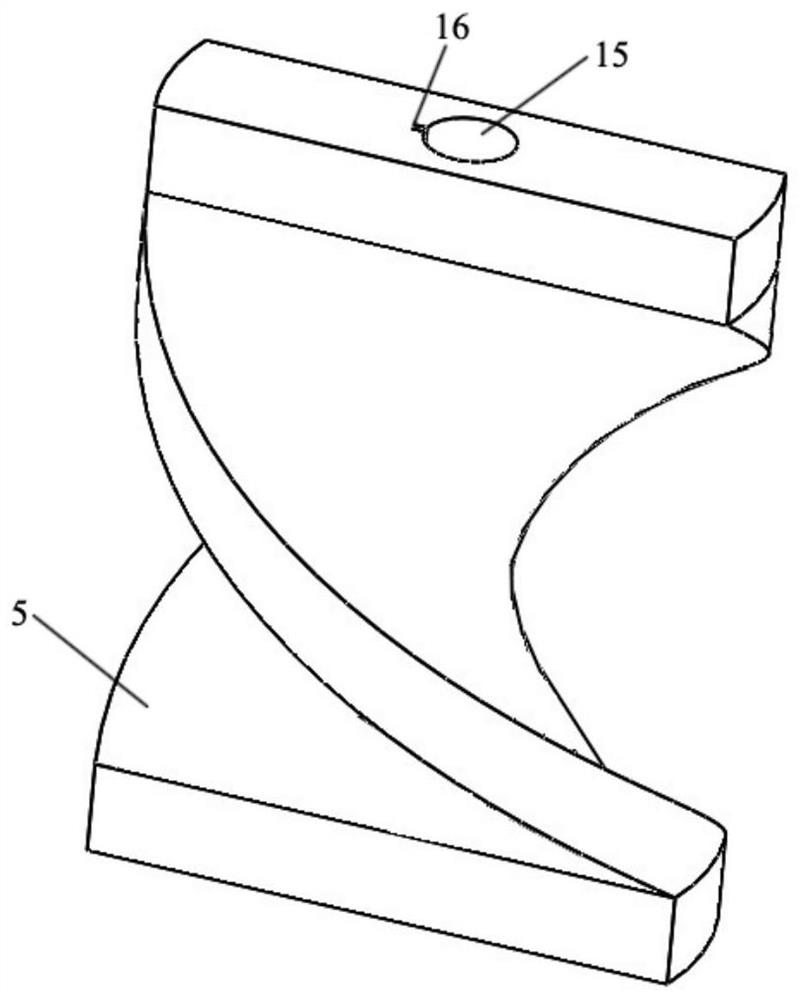

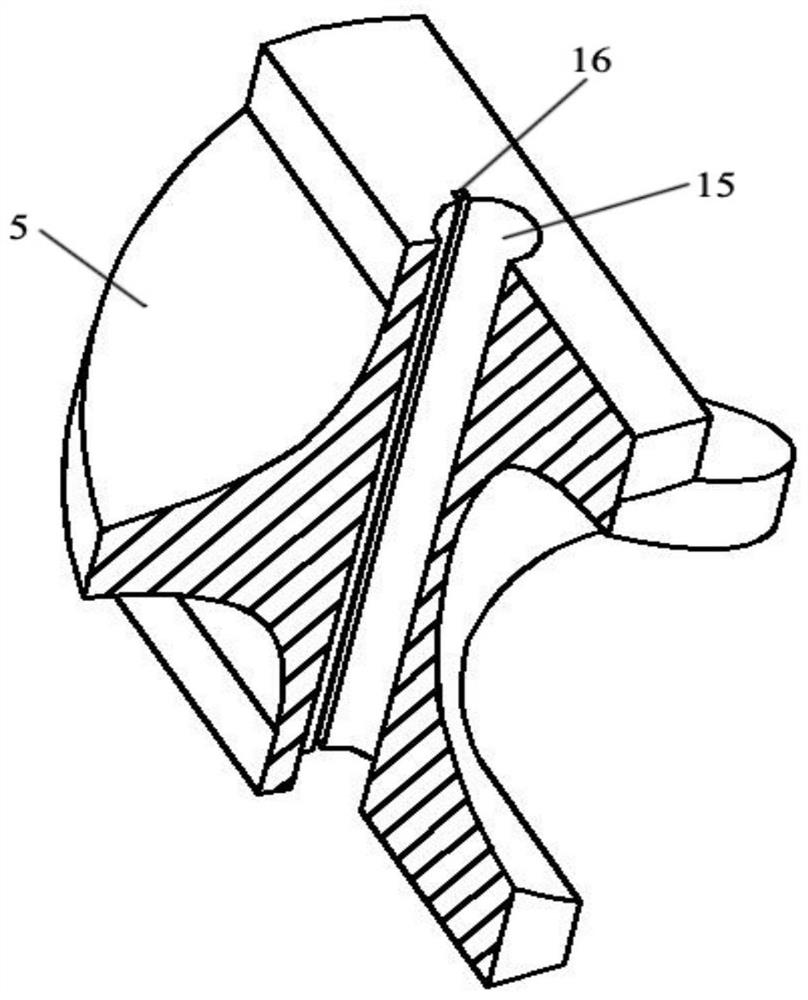

[0066] The mixing blades include counterclockwise mixing blades 5 and clockwise mixing blades 6. The external structures of the blades of the two mixing devices are helicoids. The inside of the counterclockwise mixing blades 5 has an axially penetrating counterclockwise blade mounting hole 15, and the axially penetrating The counterclockwise blade installation groove 16 is arranged on the circumferential surface of the counterclockwise blade installation hole 15; the inside of the clockwise mixing blade 6 has an axially penetrating clockwise blade installation hole 17, and the axially penetrated clockwise blade installation groove 18 is arranged on the On the circumferential surface of the clockwise blade mounting hole 15; when the angles of...

Embodiment 2

[0085] A dual-entrance self-adaptive dynamic water and fertilizer mixing method, comprising the following steps:

[0086] a. During the water and fertilizer mixing process, the irrigation water and the fertilizer solution are sent into the device through two input ports respectively, and the fertilizer solution and the fertilizer solution entering the mixing device are made to flow through the counterclockwise mixing blade 5 or the clockwise mixing blade 6. diversion of irrigation water;

[0087] b. When the divided mixed liquid enters the next adjacent clockwise mixing blade 6 or counterclockwise mixing blade 5, further mixing is carried out, and the mixed liquid is further divided into two parts by further shunting; after multiple counterclockwise mixing The repeated mixing and splitting of blade 5 and clockwise mixing blade 6 makes the mixture of irrigation water and fertilizer liquid fill the entire mixing chamber;

[0088] c. After the entire mixing chamber is filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com