Grinding device used before building wall coating

A building wall and coating technology, which is applied in the direction of grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve the problems of low grinding efficiency, dust ingress, environmental protection, etc., and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

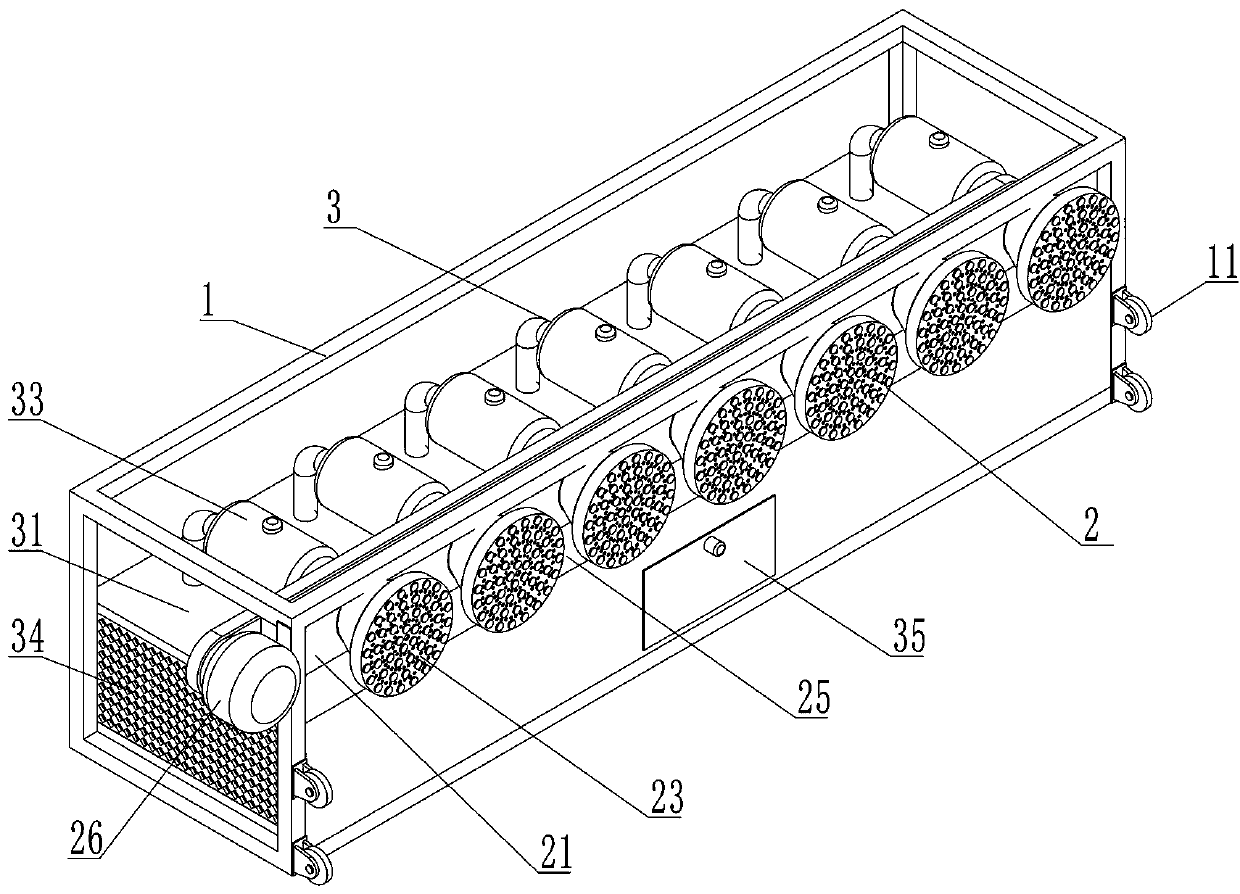

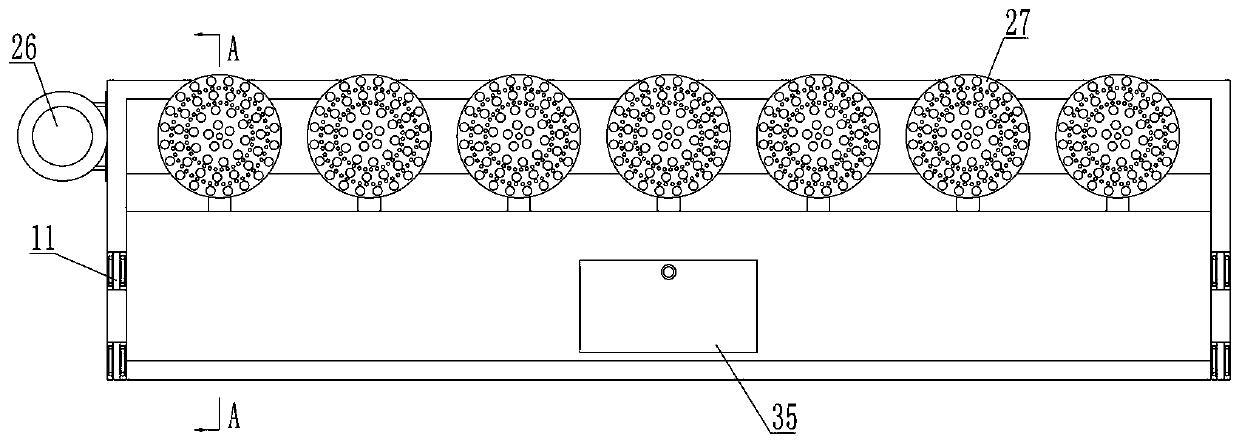

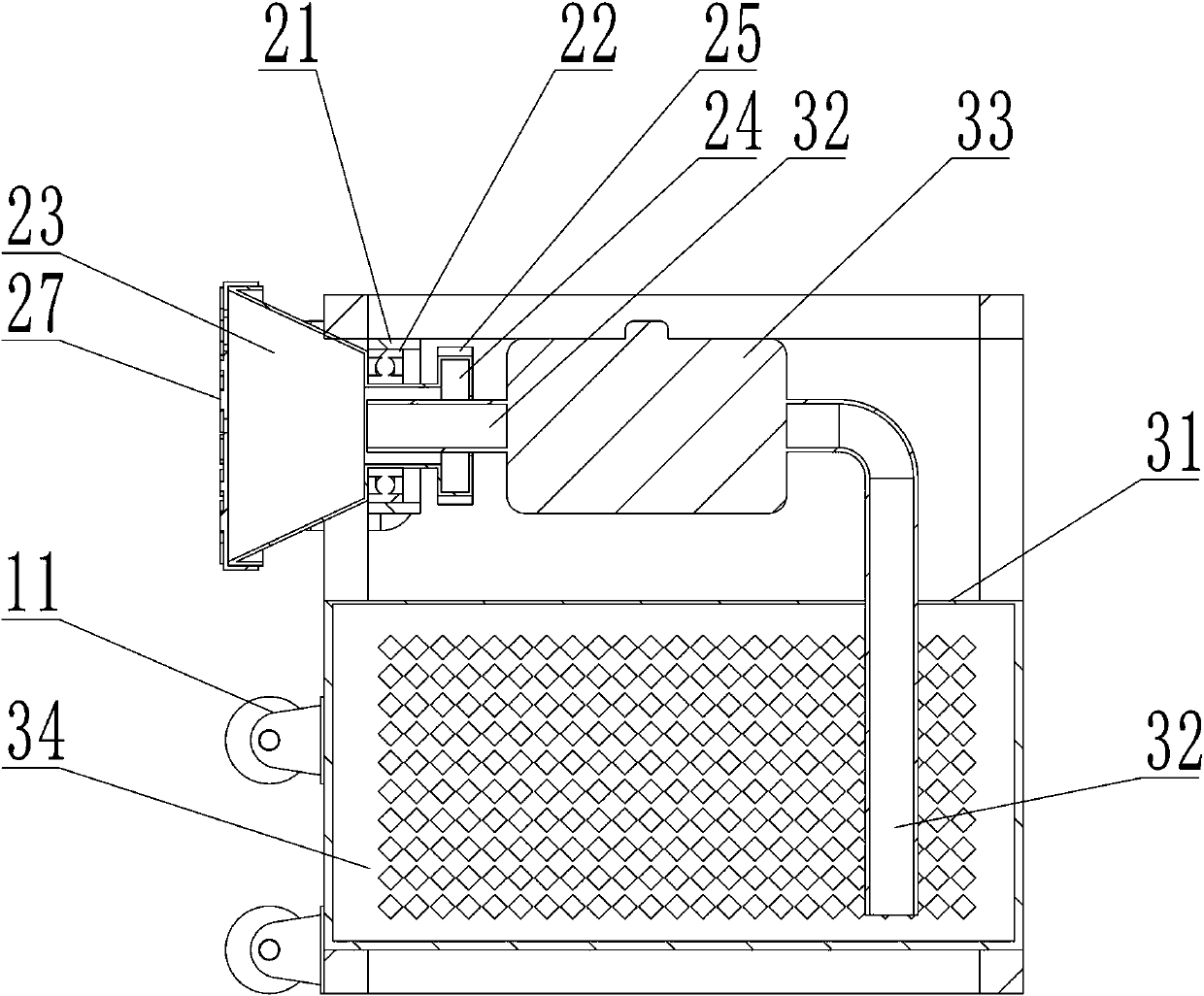

[0024] like Figure 1~Figure 3 Among them, a grinding device before coating a building wall, which includes a frame 1, a grinding mechanism 2 and a dust suction device 3; the frame 1 is a hollow frame structure, and rollers 11 are provided at both ends of the front side; The grinding mechanism 2 described includes a plurality of bearings 22 on the fixed beam 21, a grinding disc 23 cooperating with the bearing 22, a pulley 24 cooperating with the rear end of the grinding disc 23, a belt 25 and a motor 26 cooperating with the pulley 24, And the grinding sheet 27 that cooperates with the front end of the grinding disc 23; the dust suction device 3 includes a suction pipe 32 connected to the collection box 31, an exhaust fan 33 connected with the suction pipe 32; the collection box 31 is located at the bottom of the frame 1, The fixed beam 21 is positioned at the top of the collecting box 31, the motor 26 is positioned at the side of the frame 1, and the two ends of the suction pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com