Wax type production process based on metal sculptures

A production process and metal technology, which is applied in the field of wax-type production process, can solve the problems of difficult to process handicrafts and small application range, and achieve the effects of improving quality, convenient operation and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

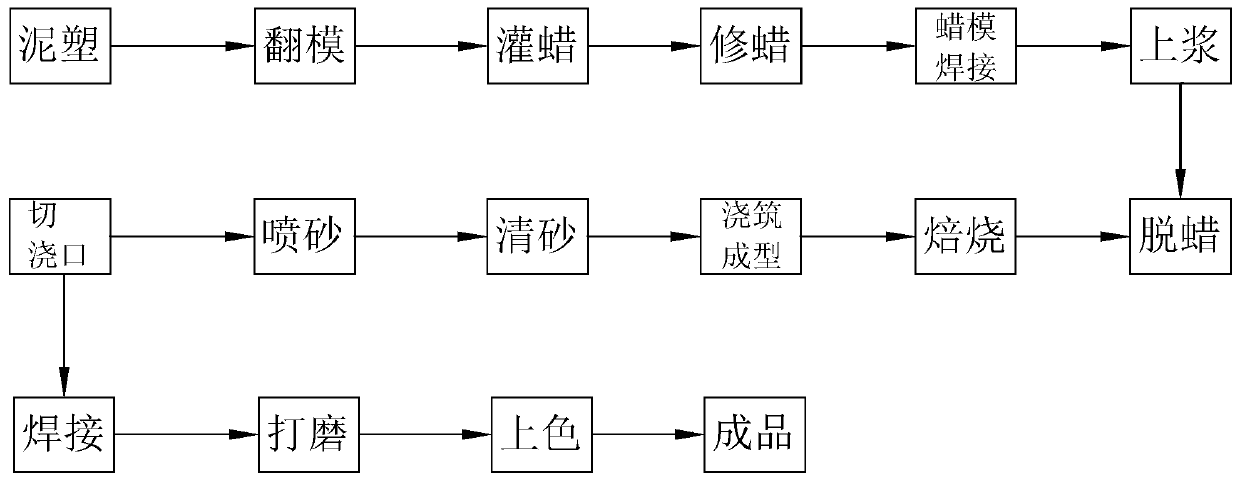

Method used

Image

Examples

Embodiment

[0053] A wax-type production process based on metal sculpture, comprising the following steps:

[0054] S01, Clay Sculpture, first select fine yellow mud and clear water to mix and mix. During the mixing process, slowly add clear water until the yellow mud and clear water are mixed into a lumpy soft mud, so that sculpture mud is made, and then, according to the drawings and customer needs Manually shape the sculpture clay, process clay sculptures of different shapes, and compare them with the drawings. After the customer confirms that they are correct, they can enter the next process;

[0055] S02, turn over the mold, first need to prepare the gypsum mixture, the gypsum mixture includes base material, the base material includes warm water and gypsum powder, and the ratio of warm water to gypsum powder is 1:1.1-1.8, during the preparation process, first add warm water and then add gypsum powder, stir it evenly, add additives during the mixing process, the additive is environmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com