Heat sealing device for multi-row bagged packaging machine

A technology of heat sealing and packaging machines, which is applied in the directions of packaging sealing/fastening, packaging, and transportation packaging. Convenient and quick opening, precise action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

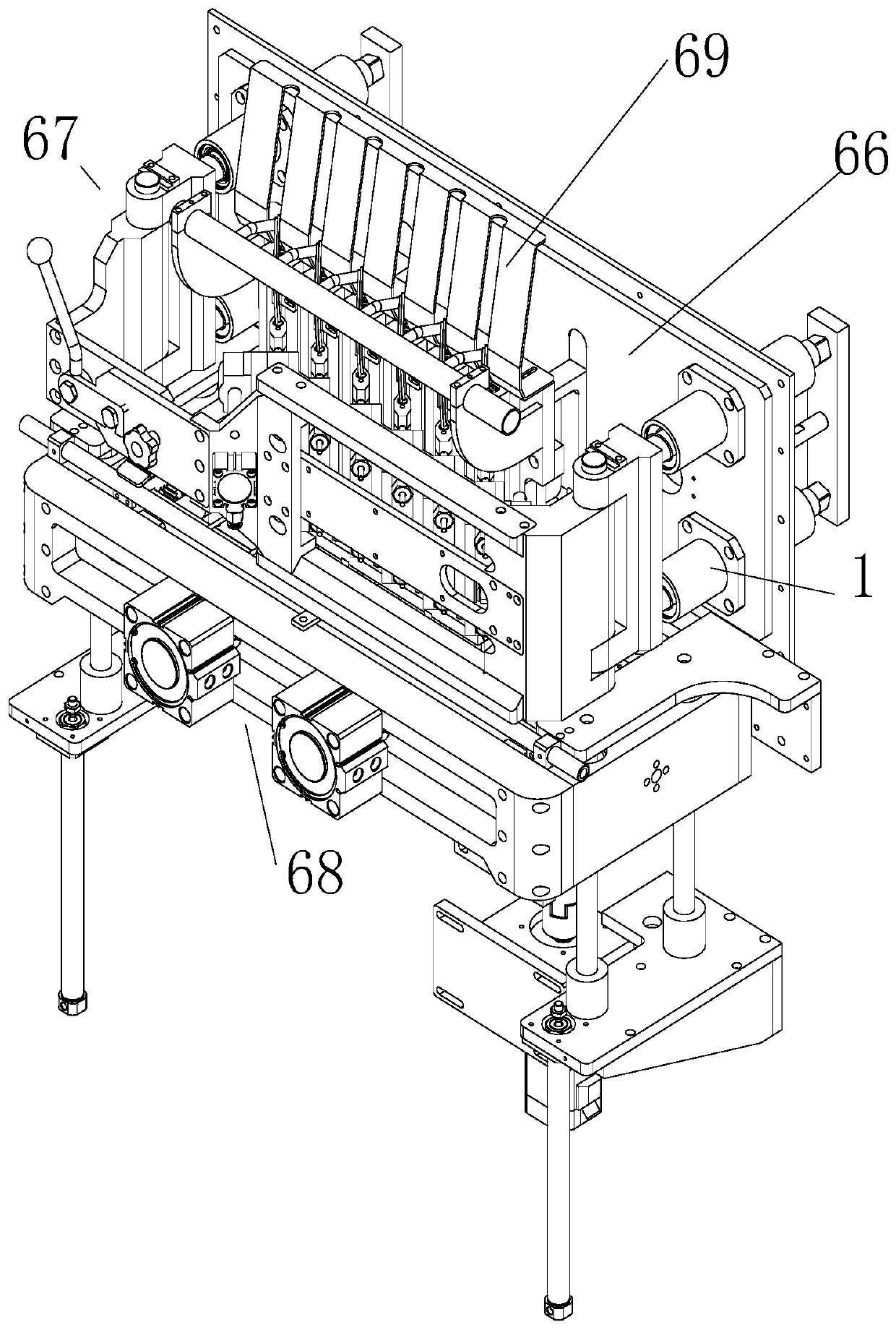

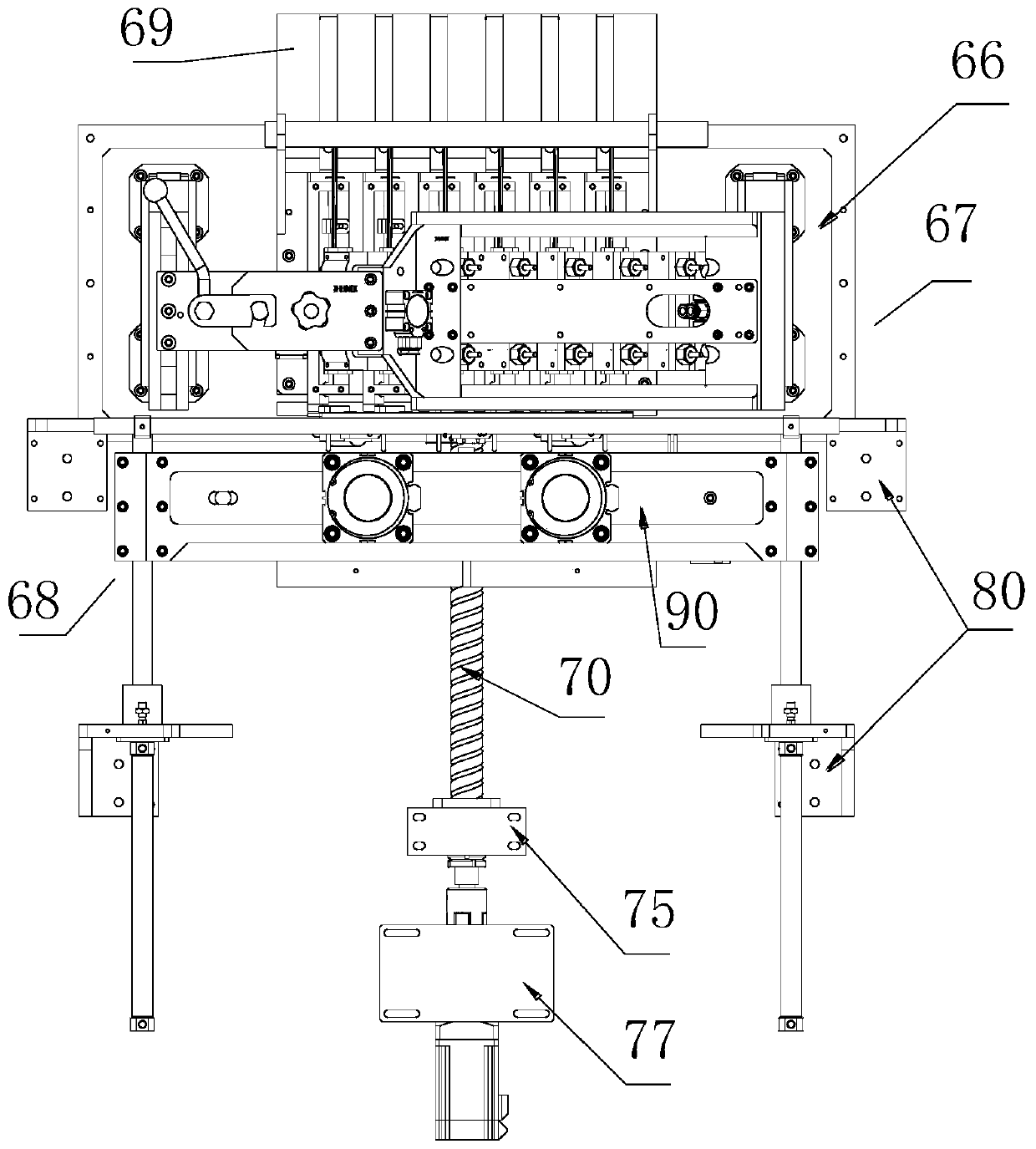

[0100] Such as Picture 1-1 , Figure 1-2 , Figure 1-3 with Figure 1-4 As shown, the present invention proposes a heat-sealing device for a multi-row bag packaging machine, including a material bag forming mechanism, a vertical sealing mechanism 67 and a horizontal sealing mechanism 68 all fixed to the frame.

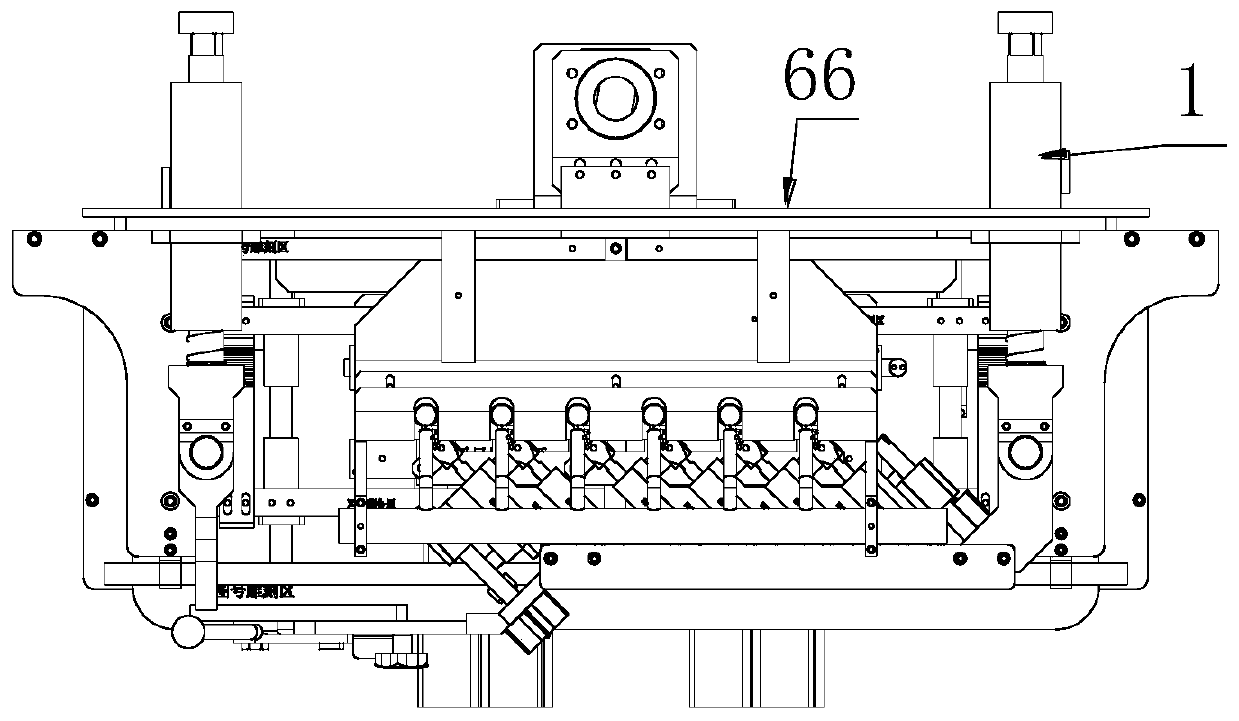

[0101] Such as diagram 2-1 , Figure 2-2 , Figure 2-3 , Figure 3-1 , Figure 3-2 with Figure 3-3 As shown, the longitudinal seal mechanism 67 includes a longitudinal seal fixed plate 66, four sets of longitudinal seal guide sleeve parts 1 and two remote vertical cylinders 4, and the four sets of longitudinal seal guide sleeve parts 1 are respectively installed on the longitudinal seal guide sleeve parts 1 in pairs. Seal the left and right ends of the large...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap