Goods loading and unloading mechanism, goods conveying device and system

A transportation device and cargo storage technology, applied in the fields of cargo transportation devices and systems, and cargo pick-and-place mechanisms, can solve the problems of reducing the total number of shelves, reducing the volume ratio of the warehouse area, affecting the storage capacity of goods, etc. High practicability and market value, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

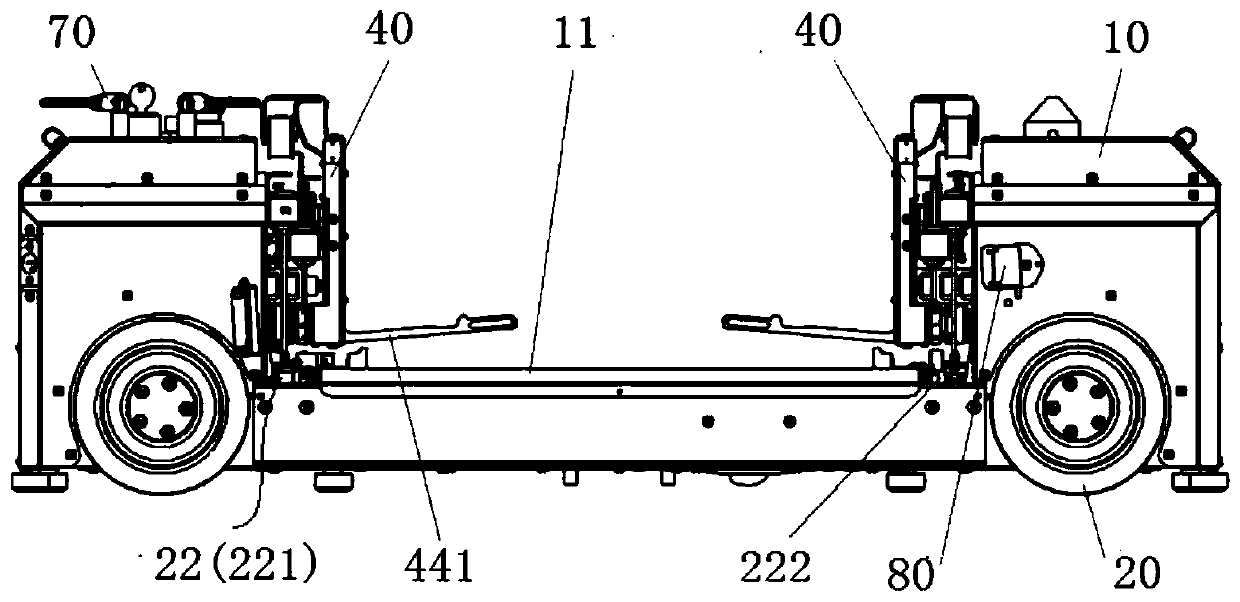

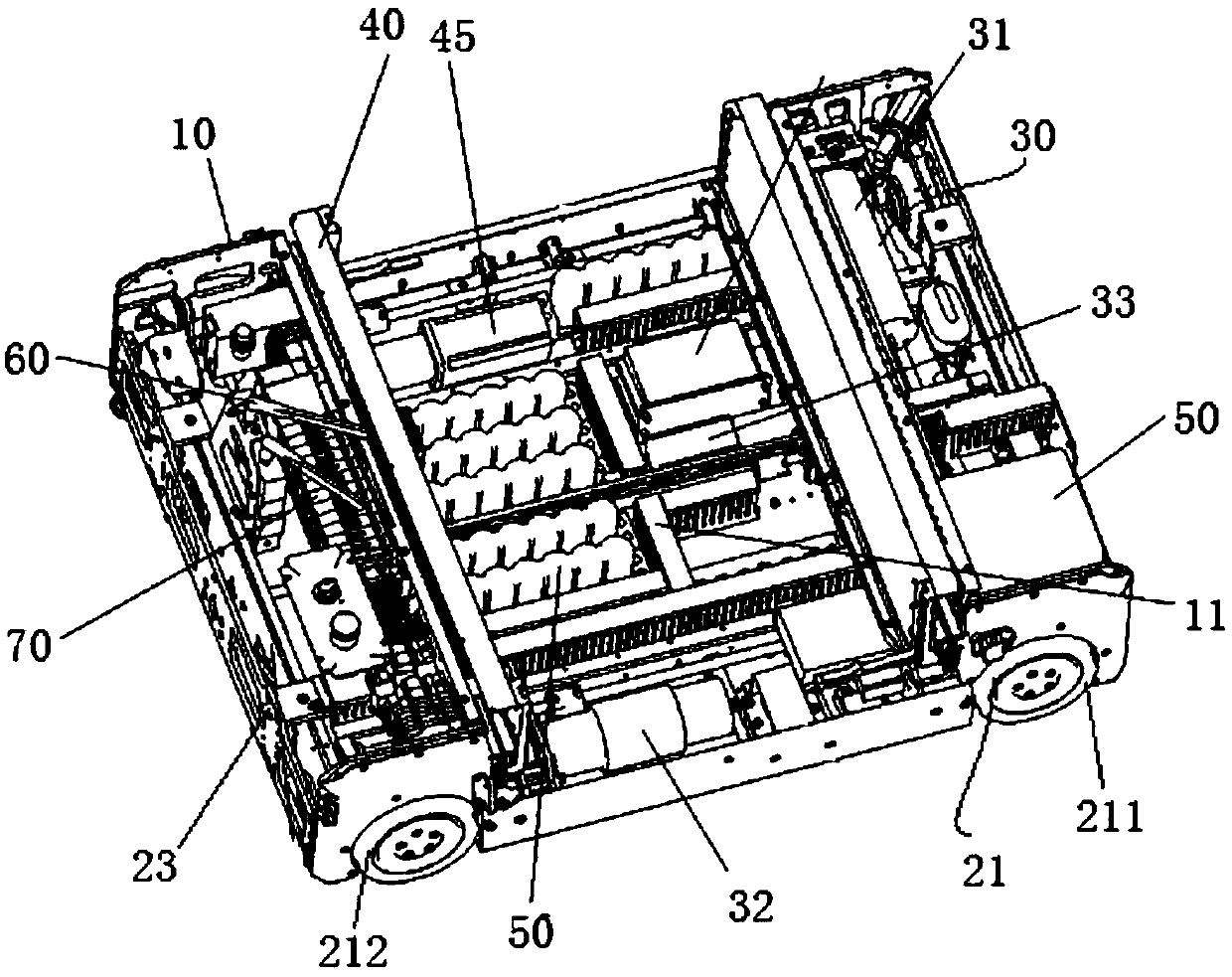

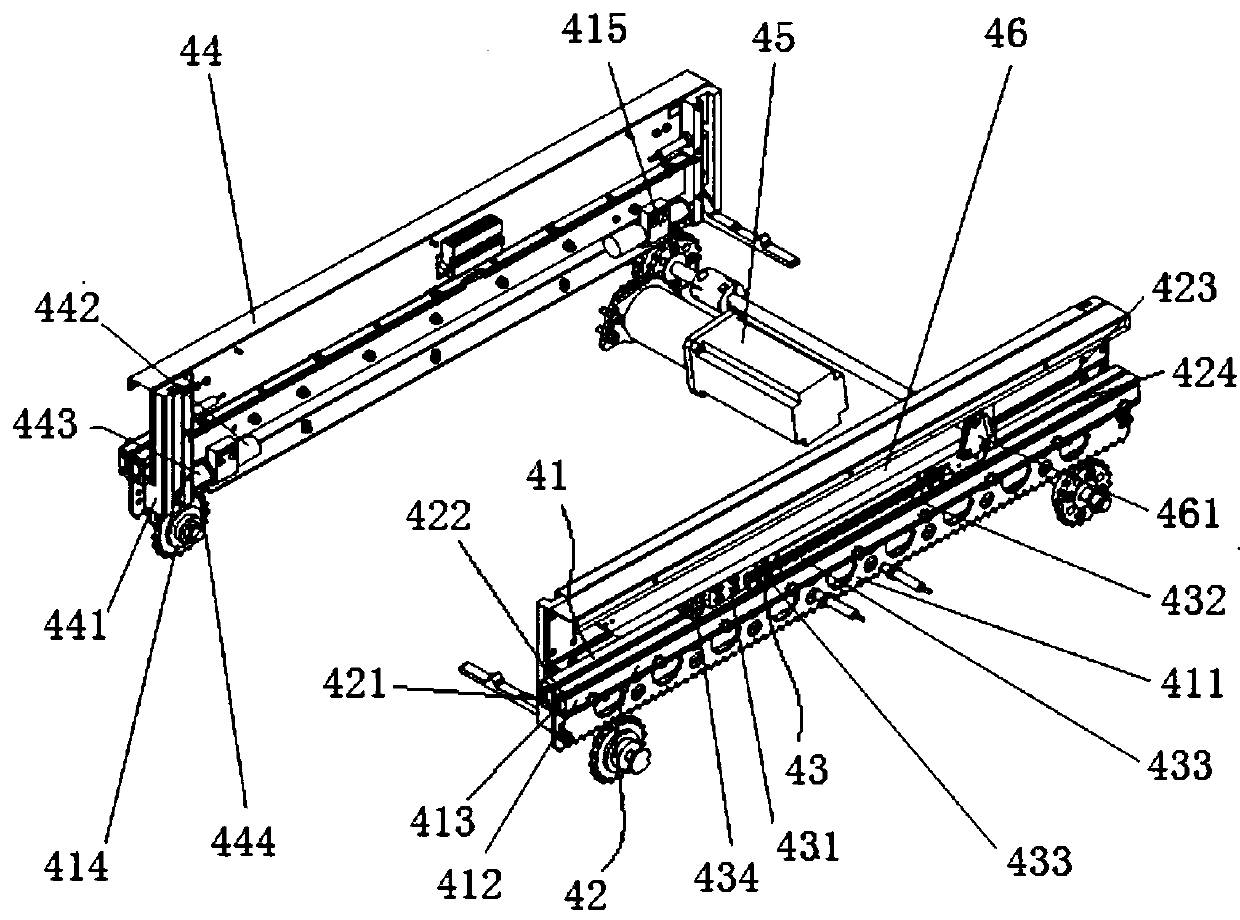

[0028] figure 1 It is a front view of the cargo conveying device according to Embodiment 1 of the present invention, figure 2 It is a schematic diagram of the internal structure of the cargo conveying device according to Embodiment 1 of the present invention.

[0029] Such as figure 1 with figure 2 As shown, the cargo delivery device 100 in the present embodiment one is a shuttle car, the height of the shuttle car is 300mm, and it is arranged in the low-level multi-storey warehouse. The minimum layer spacing of the shelves of the three-dimensional warehouse is 300mm. The goods are material boxes, and the height of the material box is less than or equal to 150mm.

[0030] The goods delivery device 100 is used to obtain goods from the storage line in the three-dimensional warehouse and move and store them in the warehouse in the corresponding three-dimensional warehouse, or take the goods out of the warehouse and move them to the outbound line in the three-dimensional wareh...

Embodiment 2

[0085] Figure 5 It is a structural block diagram of the cargo delivery system in Embodiment 2 of the present invention.

[0086] Such as Figure 5 As shown, the goods delivery system 200 in the second embodiment is used for mobile storage of the goods in the three-dimensional warehouse, and includes at least one goods delivery device 100 and the control device 300 in .

[0087] The control device 300 is used to send a control command to the cargo conveying device, so that the cargo conveying device 100 can pick up and place the cargo according to the control command. In this embodiment, the control device 300 is a computer communicatively connected with the goods delivery device 100 .

[0088] In the second embodiment, the cargo delivery device 100 further includes a shuttle car communication unit 60 , a shuttle car control unit 70 and a shuttle car detection unit 80 .

[0089] The shuttle communication unit 60 is a communication module with a communication function, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap