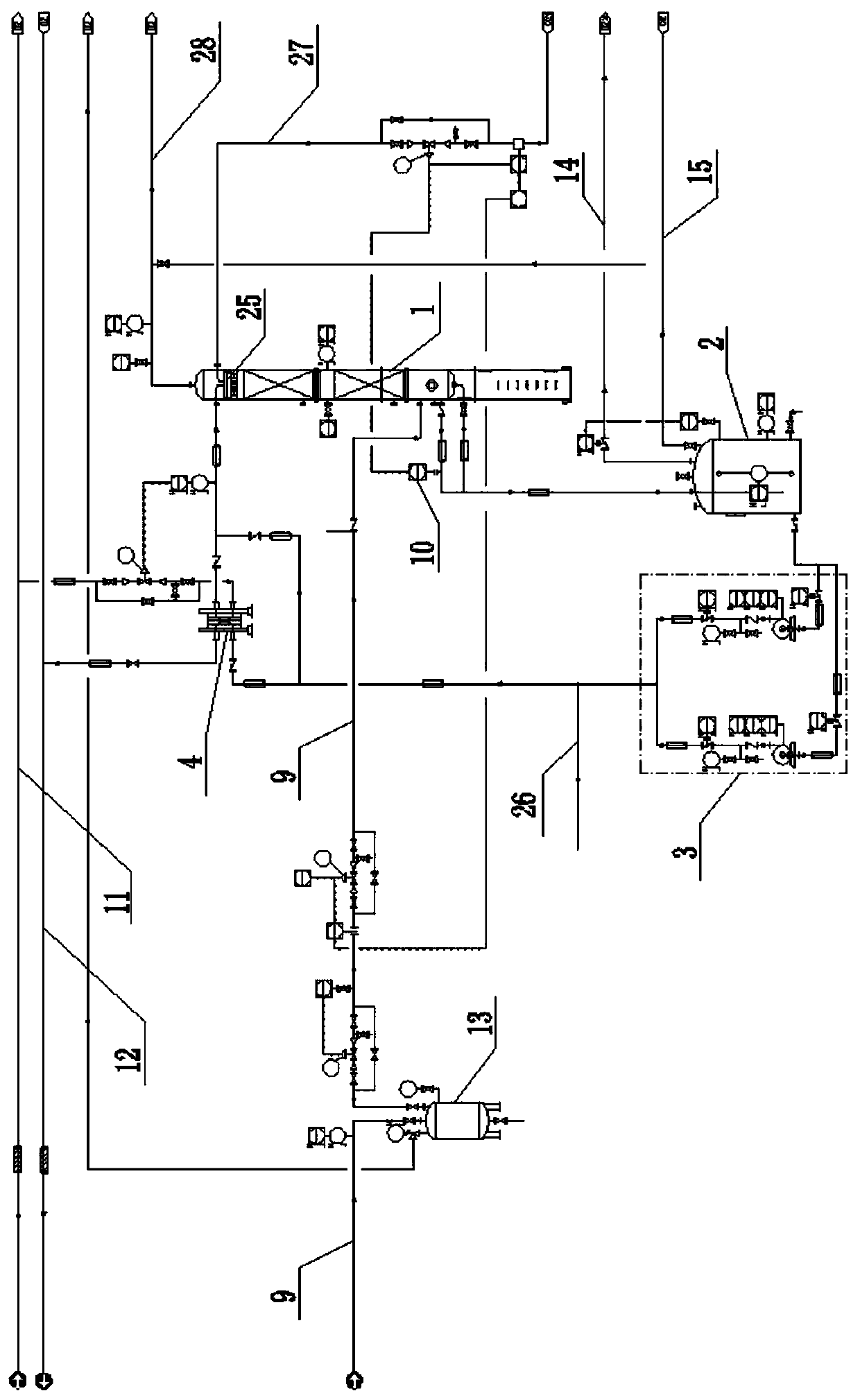

System and technology for producing sodium hypochlorite by tower-type continuous method

A technology of sodium hypochlorite and sodium hypochlorite solution, which is applied in the direction of hypochlorous acid, hypochlorite, chemical instruments and methods, etc. It can solve the problems of unstable product quality, easy salt collection and blockage, etc., and achieve continuous stable production, energy saving and environmental protection Good, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

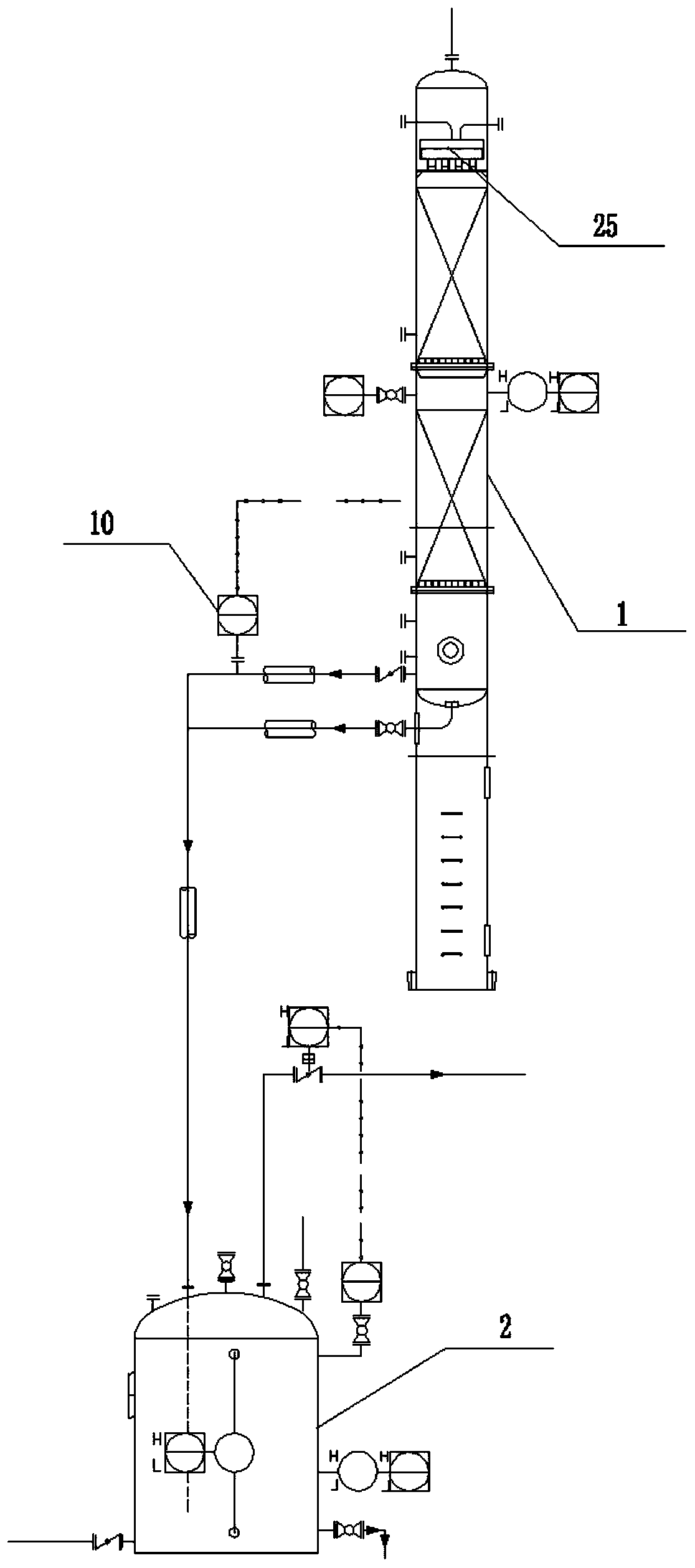

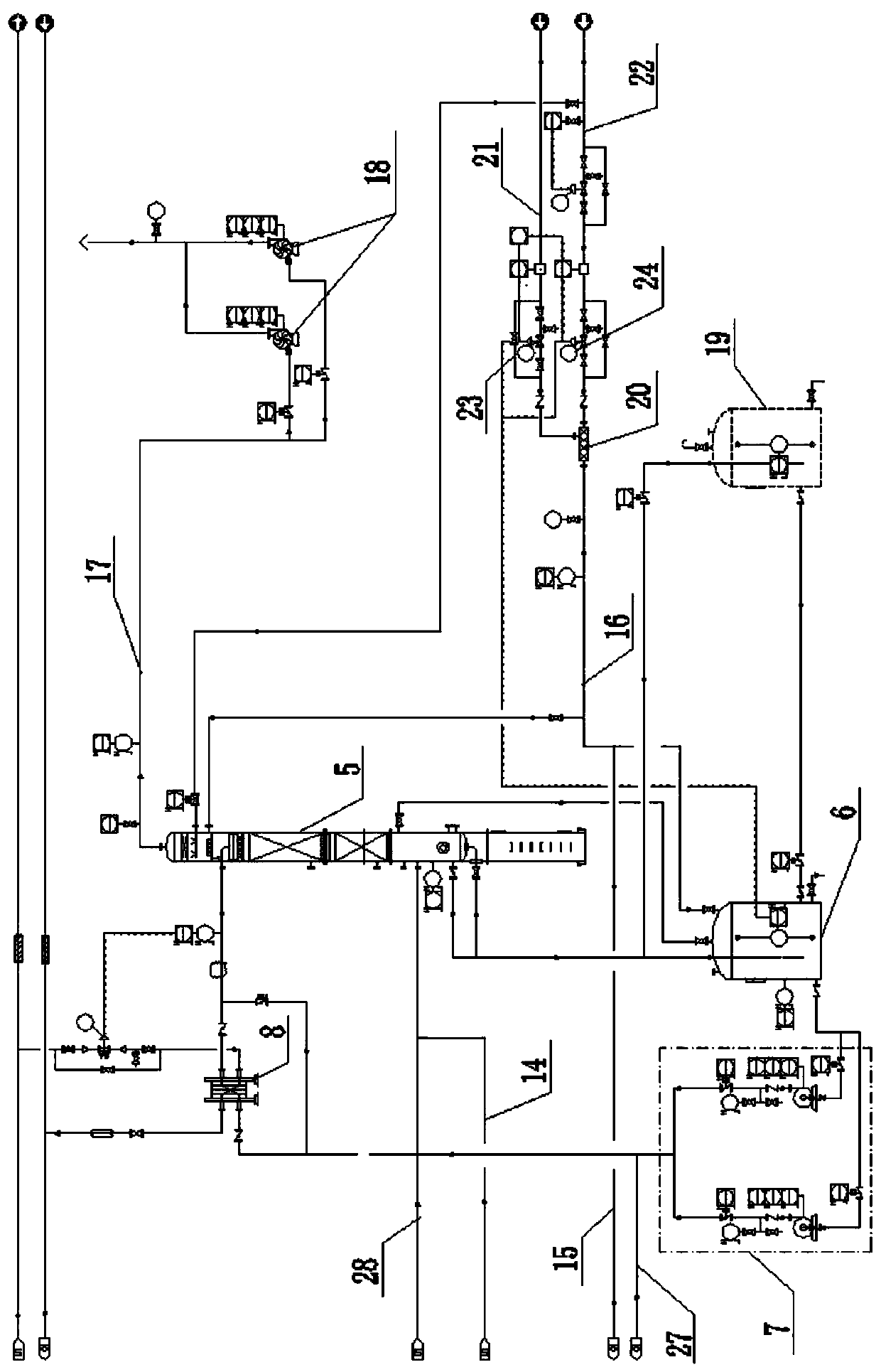

[0034] refer to Figure 1~4 , a device for producing sodium hypochlorite by a continuous tower method, said device comprising a sodium hypochlorite reaction mechanism and a tail chlorine absorption mechanism, said sodium hypochlorite reaction mechanism comprising a sodium hypochlorite reaction tower 1, a sodium hypochlorite circulation tank 2, a sodium hypochlorite circulation pump 3, a sodium hypochlorite cooler 4 , the tail chlorine absorption mechanism comprises tail chlorine absorption tower 5, lye circulation tank 6, lye circulation pump 7, lye cooler 8, and described sodium hypochlorite circulation tank 2 passes through sodium hypochlorite circulation pump 3, sodium hypochlorite cooler 4 successively It is connected with the sodium hypochlorite reaction tower 1 top,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com