Epoxy group electroconductive heat-conducting adhesive and preparation method thereof

A technology of electrical and thermal conductivity and adhesives, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of reducing regularity, defects, affecting graphene mechanics, and enhancing the effect of electrical and thermal conductivity, etc., to solve the problem of poor toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

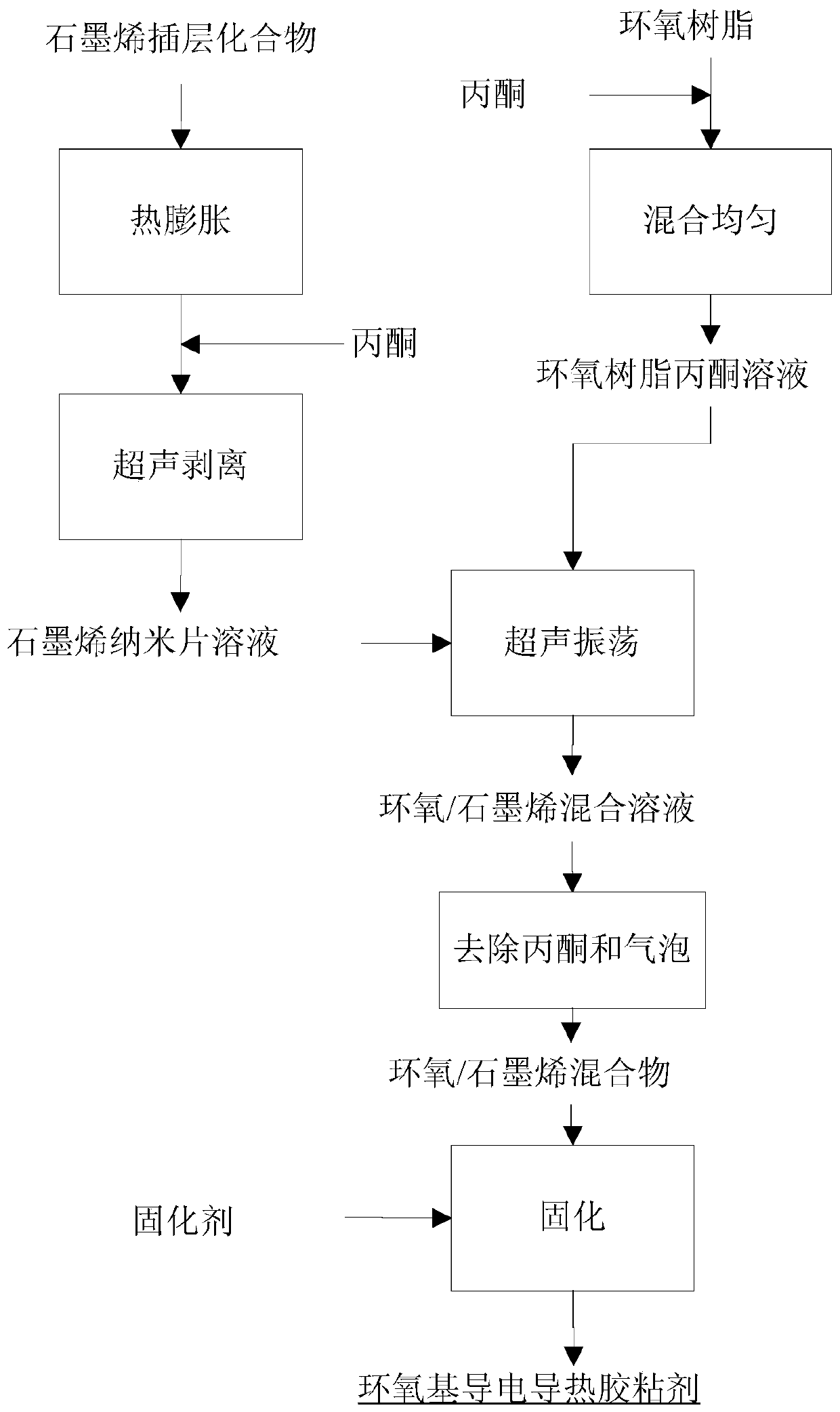

[0042] A preparation method of epoxy-based conductive heat-conducting adhesive, the preparation process flow chart is shown in figure 1 , including the following steps:

[0043] Step 1: Thermally expand the graphene intercalation compound at 700°C for 1 min, then add acetone, and ultrasonically peel off for 30 min to obtain a graphene nanosheet solution; wherein, in the graphene nanosheet solution, the concentration of graphene nanosheets is 0.01g / mL; Among them, the ultrasonic power is 100W, the ultrasonic work is 2s, and the pause is 1s.

[0044] By carrying out transmission electron microscopy analysis and testing on graphene nanosheets in the graphene nanosheet solution, the obtained transmission electron microscope diagram is shown in Image 6 Middle picture (a), picture (b), picture (c), graphene structure and atomic scale details can be observed from picture (a), which shows transparency, which proves that it is few-layer graphene, combined with picture (b) ) and Figu...

Embodiment 2

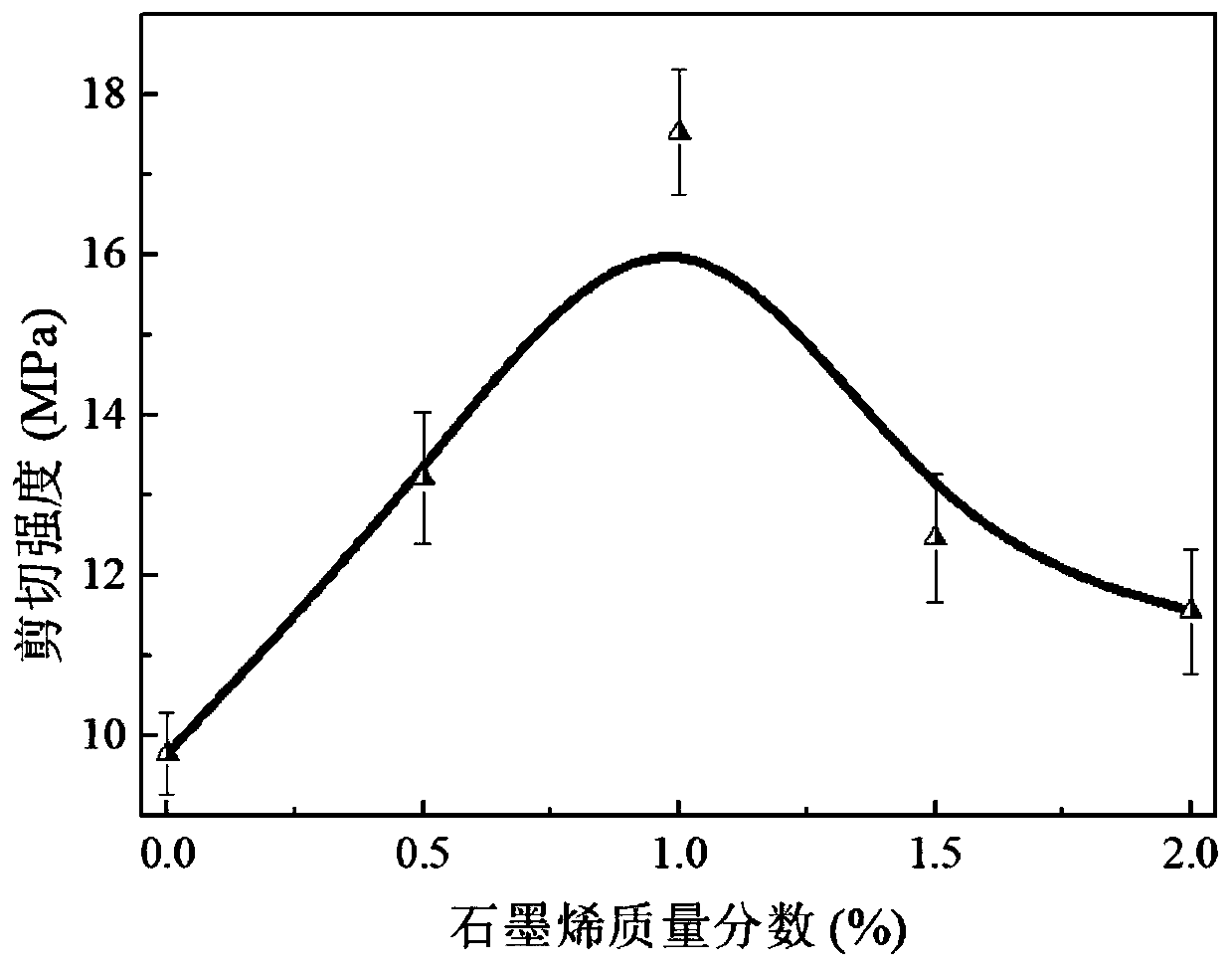

[0050] A kind of preparation method of epoxy-based conductive heat-conducting adhesive, with embodiment 1, difference is:

[0051] In step 2, according to the mass ratio, the quality of the graphene nanosheets: epoxy resin+curing agent+graphene nanosheets=0.8:100.

Embodiment 3

[0053]A kind of preparation method of epoxy-based conductive heat-conducting adhesive, with embodiment 1, difference is:

[0054] In step 2, by mass ratio, graphene nanosheets: epoxy resin+curing agent+graphene nanosheets=1.0:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com