LNG (liquefied natural gas) pipeline precooling method and NG (natural gas) cool air generating device

A technology for generating device and air-conditioning, which is applied in the direction of combination device, separation method, chemical instrument and method, etc., to achieve the effect of small equipment footprint, reduced banana effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0029] The method for precooling an LNG pipeline according to the present invention uses the sensible heat of NG at normal temperature to vaporize the LNG to form NG cold air, and uses the NG cold air to precool the LNG pipeline.

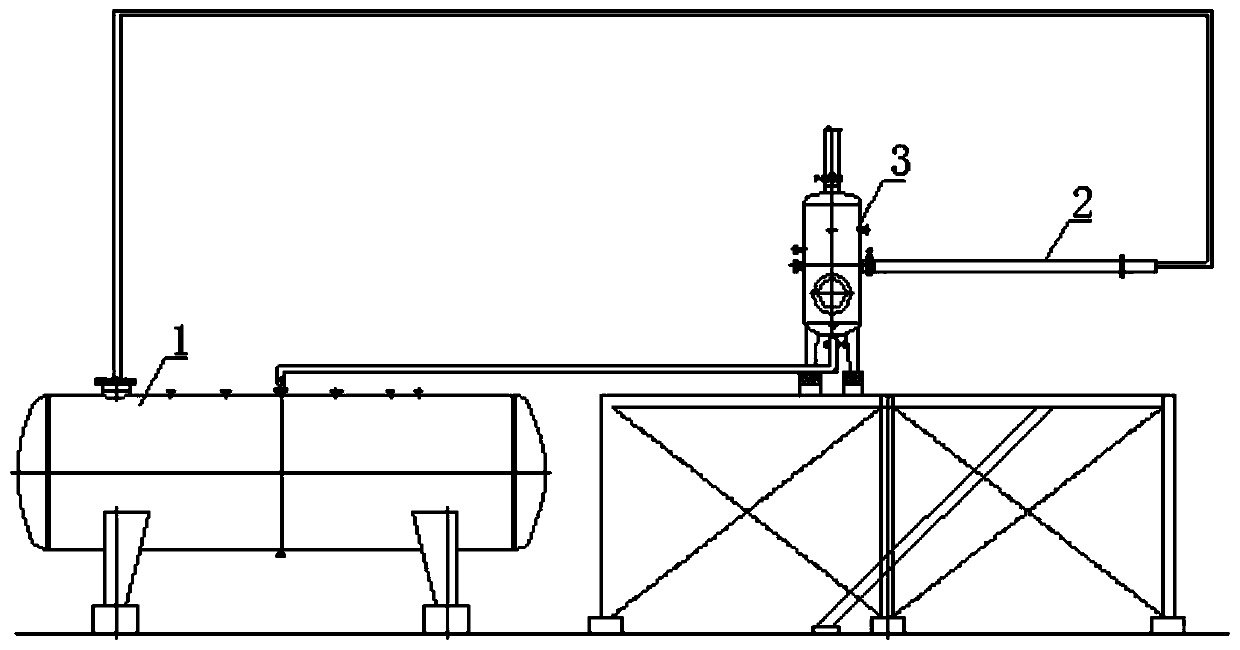

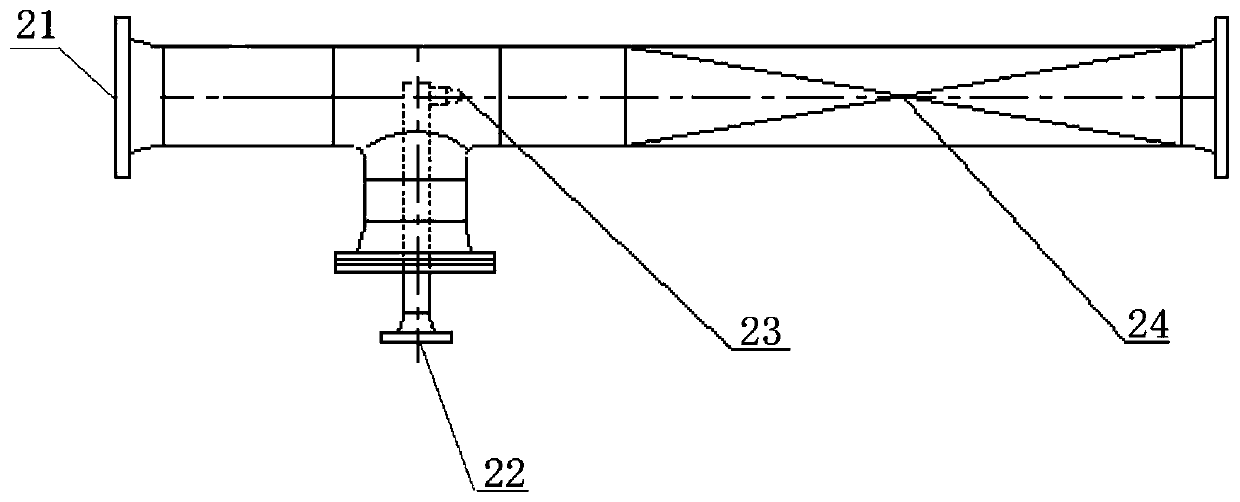

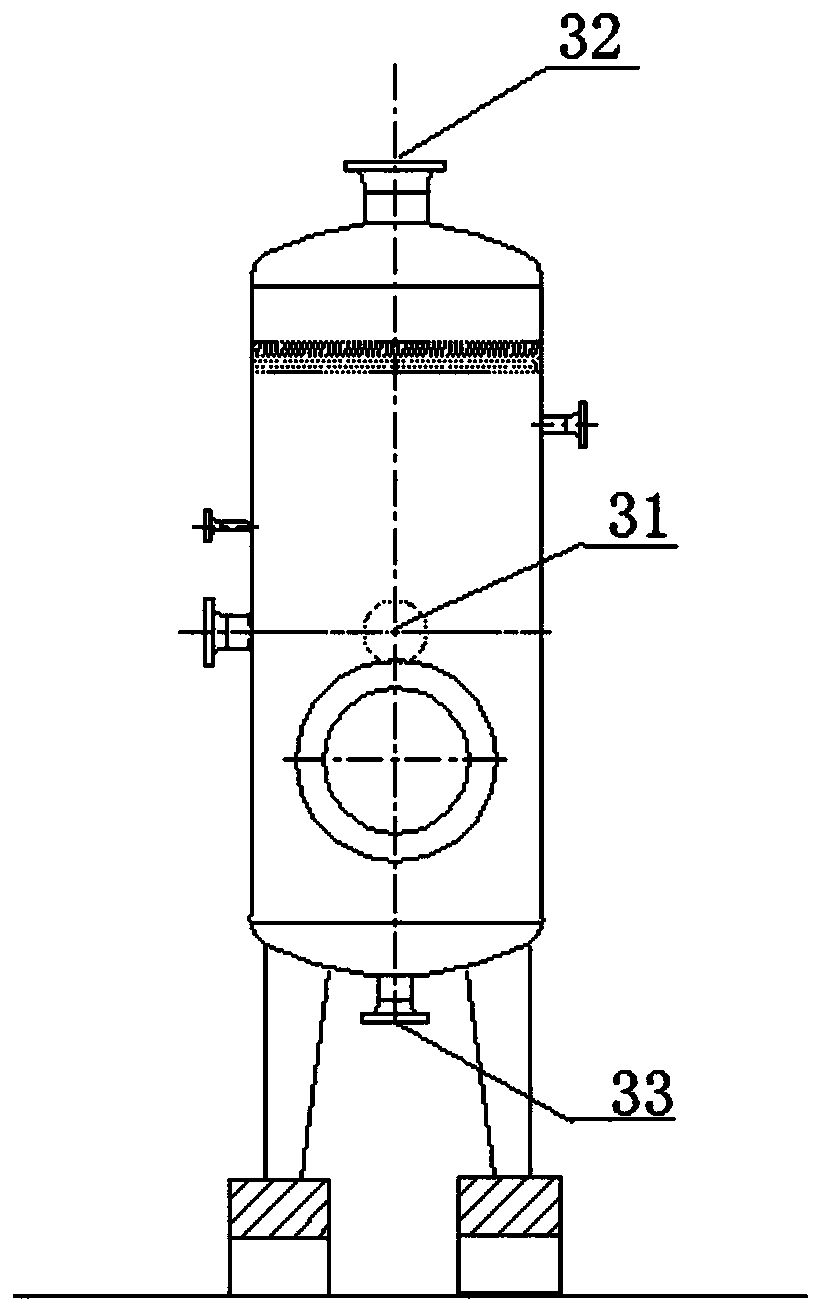

[0030] Such as Figure 4 As shown, a kind of LNG pipeline precooling method described in the present invention is specifically: the LNG from the LNG discharge tank 1 is fully mixed with normal temperature NG in the LNG mixing device 2 to produce low-temperature NG atomized gas and low-temperature NG mist The gas is separated by the LNG gas-liquid separator 3 to obtain dry NG cold air, which is used as the pre-cooling circulating gas before the LNG pipeline and equipment start; the liquid separated by the LNG gas-liquid separator 3 is returned to the LNG discharge tank 1.

[0031] Such as figure 1 As shown, a kind of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com