Hot aggregate temperature control device for asphalt mixture stirring station and control method thereof

A temperature control device, asphalt mixture technology, applied in the direction of roads, road repair, roads, etc., can solve the problem of slow response speed of burner heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

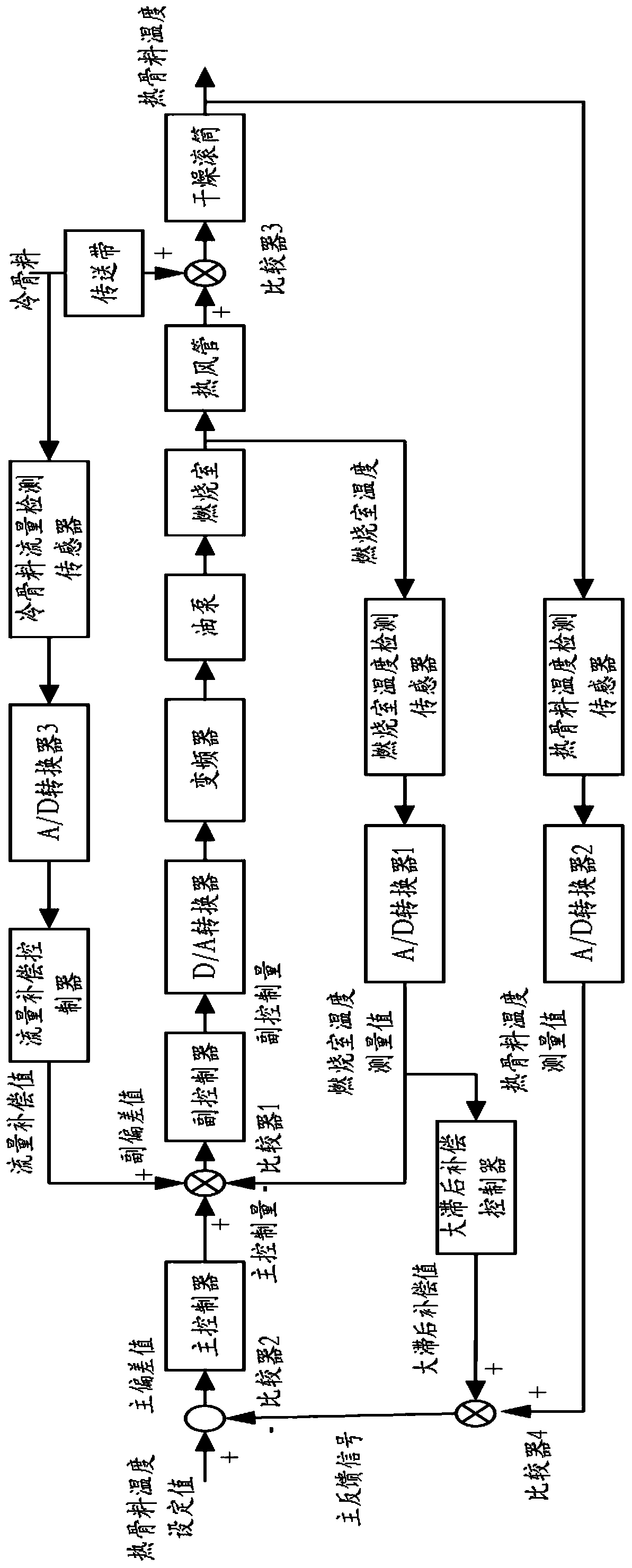

[0037] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] Refer to attached figure 1 A thermal aggregate temperature control method for an asphalt mixing plant comprises the following steps:

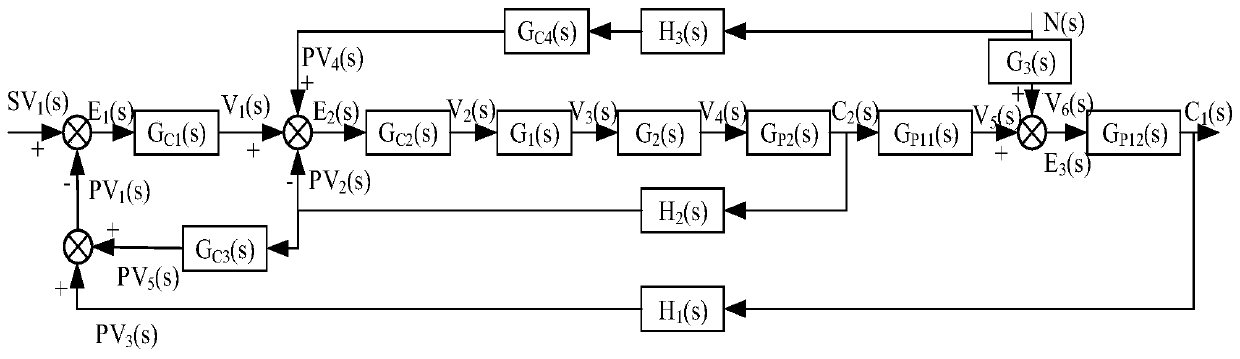

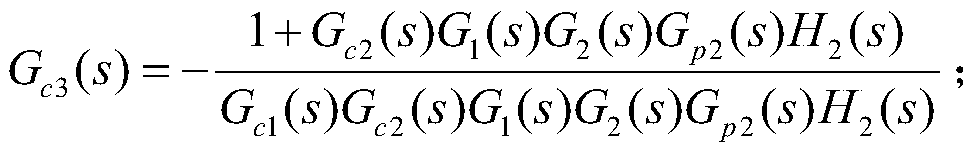

[0039] Step 1, establish the transfer function G of the D / A converter and the frequency converter 1 (s), the transfer function G of the oil pump 2 (s), the transfer function G of the conveyor belt 3 (s), transfer function H of thermal aggregate temperature detection sensor and A / D converter 2 1 (s), the transfer function H of the combustion chamber temperature detection sensor and A / D converter 1 2 (s), the transfer function H of aggregate flow detection sensor and A / D converter 3 3 (s), the transfer function G of the hot air pipe p11 (s), the transfer function G of the drying drum p12 (s), the transfer function G of the combustion chamber p2 (s); Design the transfer function G of the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com