Conical anti-slide tie anchoring strand stayed cable with forked ear and construction method of cable

A technology of anti-skid keys and steel strands, which is applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of high anchorage production cost, low ability to resist wind and rain excitation, and large wind resistance coefficient of cables, etc., to achieve The effect of saving raw materials, saving materials, and reducing the distance between anchor plate holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

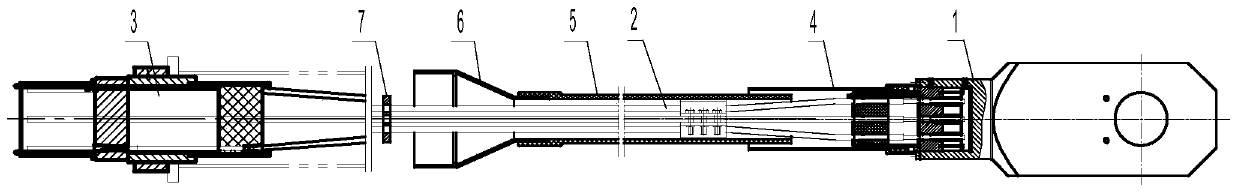

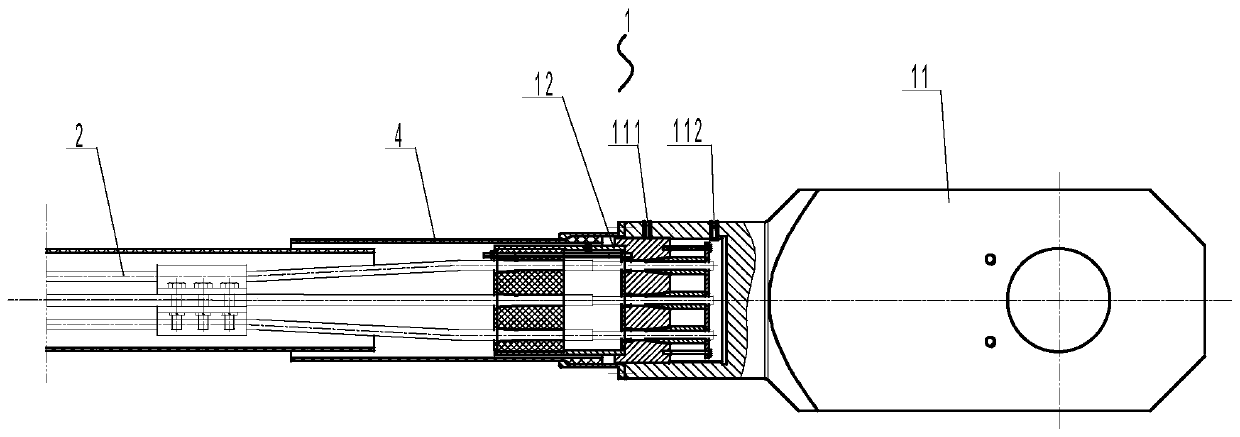

[0083] An anti-skid key with fork lugs for anchoring a steel strand cable, comprising a fixed-end anchor 1 with fork lugs, a cable body 2, and a tension-end anchor 3, wherein:

[0084] The cable body 2 is a steel strand bundle composed of multiple parallel unbonded prestressed steel strands, and each strand of unbonded prestressed steel strands (hereinafter referred to as steel strands) is a PE sheathed steel strand Wire, and both ends of the steel strand are bare steel strands after stripping the PE sheath;

[0085] The fixed-end anchor 1 with fork lugs includes fork lugs 11, conical anti-skid key anchorage anchors 12;

[0086] The fork lug is a conventional structure, the upper end of the fork lug has two side lug plates, and the two side lug plates are provided with coaxial pin holes; the lower end of the fork lug has an internal thread hole for connecting the anchor;

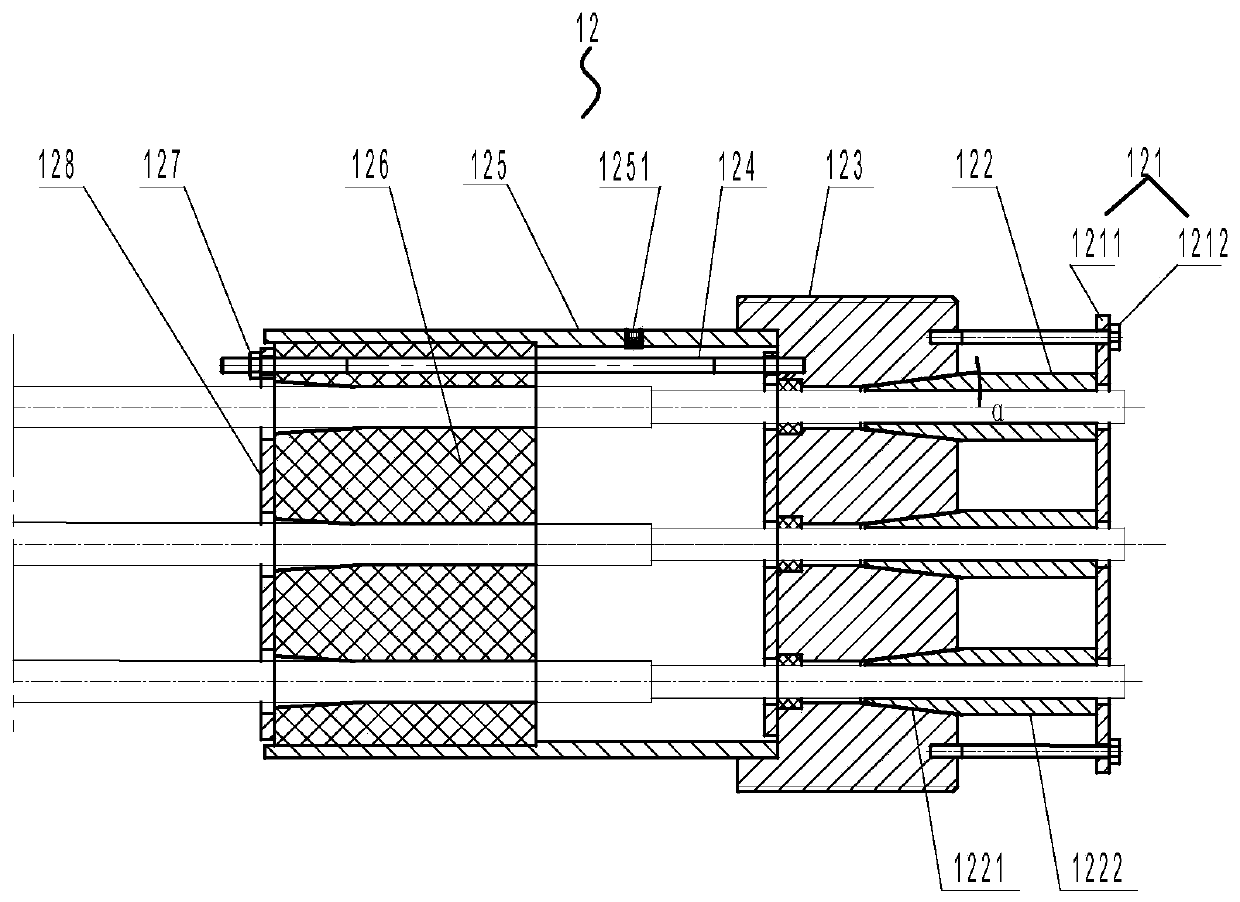

[0087] The conical anti-skid key anchor 12 includes a conical anti-skid key 122, an anchor plate 123, a ...

Embodiment 2

[0096] An anchoring steel strand cable with a fork ear cone type anti-skid key, the basic structure of the cable is the same as that of Embodiment 1, including a fixed end anchor with fork ears 1, a cable body 2, and a tension end anchor 3. The difference is that the positions of the filling holes are different. There is no filling hole A on the sealing cylinder 125 of the second embodiment, and there is no filling hole B112 on the lower end of the fork ear 11. On the anchor plate 123 along the axis There are symmetrical perfusion holes C and perfusion holes D. The concrete structure of present embodiment two is as follows:

[0097] An anti-skid key with fork lugs for anchoring a steel strand cable, comprising a fixed-end anchor 1 with fork lugs, a cable body 2, and a tension-end anchor 3, wherein:

[0098] The cable body 2 is a steel strand bundle composed of multiple parallel unbonded prestressed steel strands, and each strand of unbonded prestressed steel strands (hereinaf...

Embodiment 3

[0110] A construction method for anchoring a steel strand cable with a fork ear cone type anti-skid key as described in Embodiment 1. The method is to first fix the anchorage at the tension end on the pre-embedded pressure-bearing embedded part at the end of the beam , then pass the steel strand through the conical anti-skid key anchorage, and squeeze the conical anti-skid key at one end of the steel strand, so that the conical outer surface of the conical anti-skid key is embedded in the cone of the anchor plate In the hole; connect the fork lugs with the conical anti-skid key anchorage to form a fixed-end anchorage with fork lugs, and pin the fixed-end anchorage with fork lugs to the lug plate at the tower end; the traction steel strand The other end passes through the anchorage at the tension end, and a single steel strand is stretched with a tension jack until the cable force is calculated and then anchored, until all the steel strands are installed and tensioned, then the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap