Novel fabricated column foot connecting node and mounting method thereof

A connection node, prefabricated technology, applied in the direction of architecture, building structure, etc., can solve the problems of less R&D and production, lack of nodes in the position of column bases, etc., to avoid welding, easy installation and disassembly, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

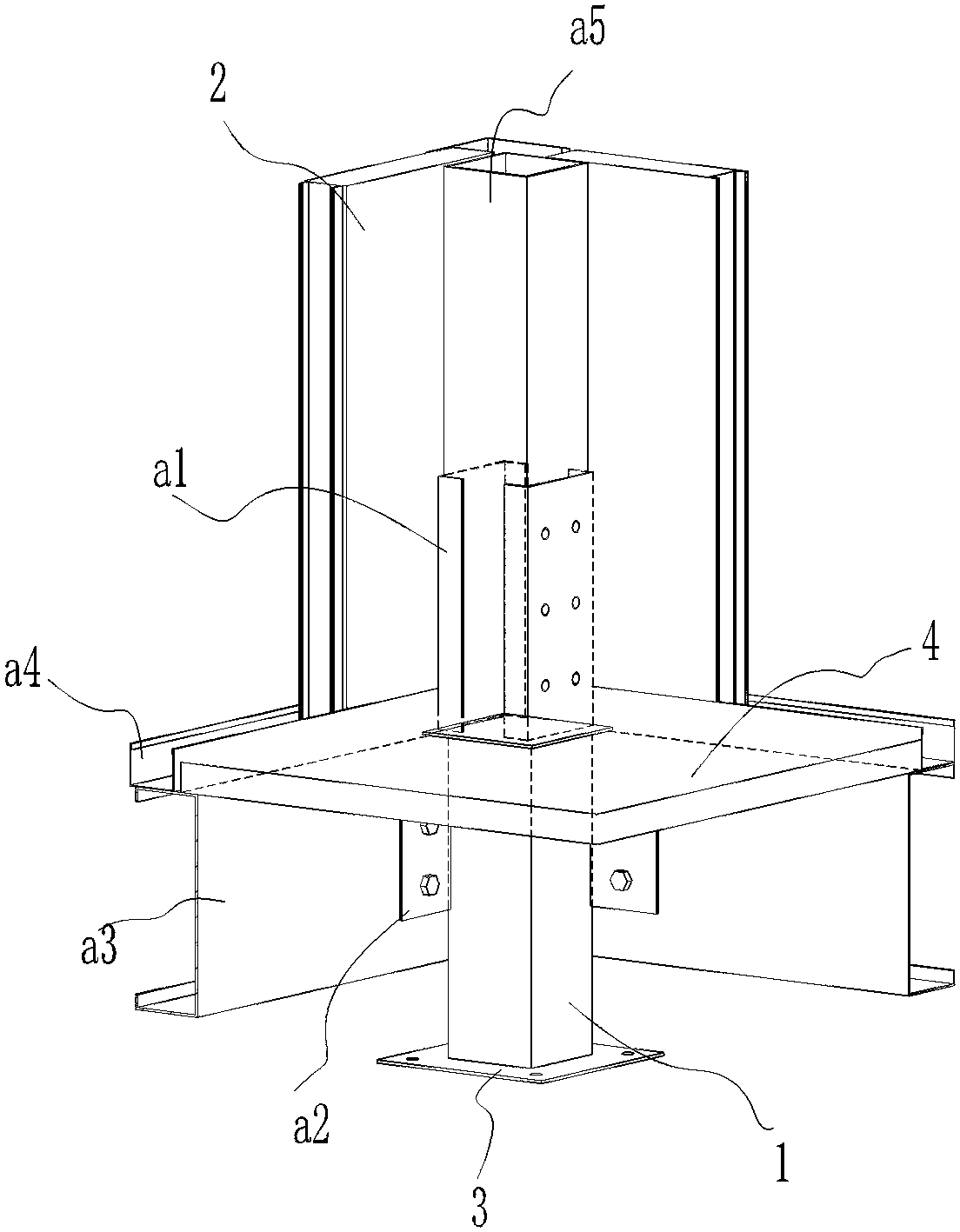

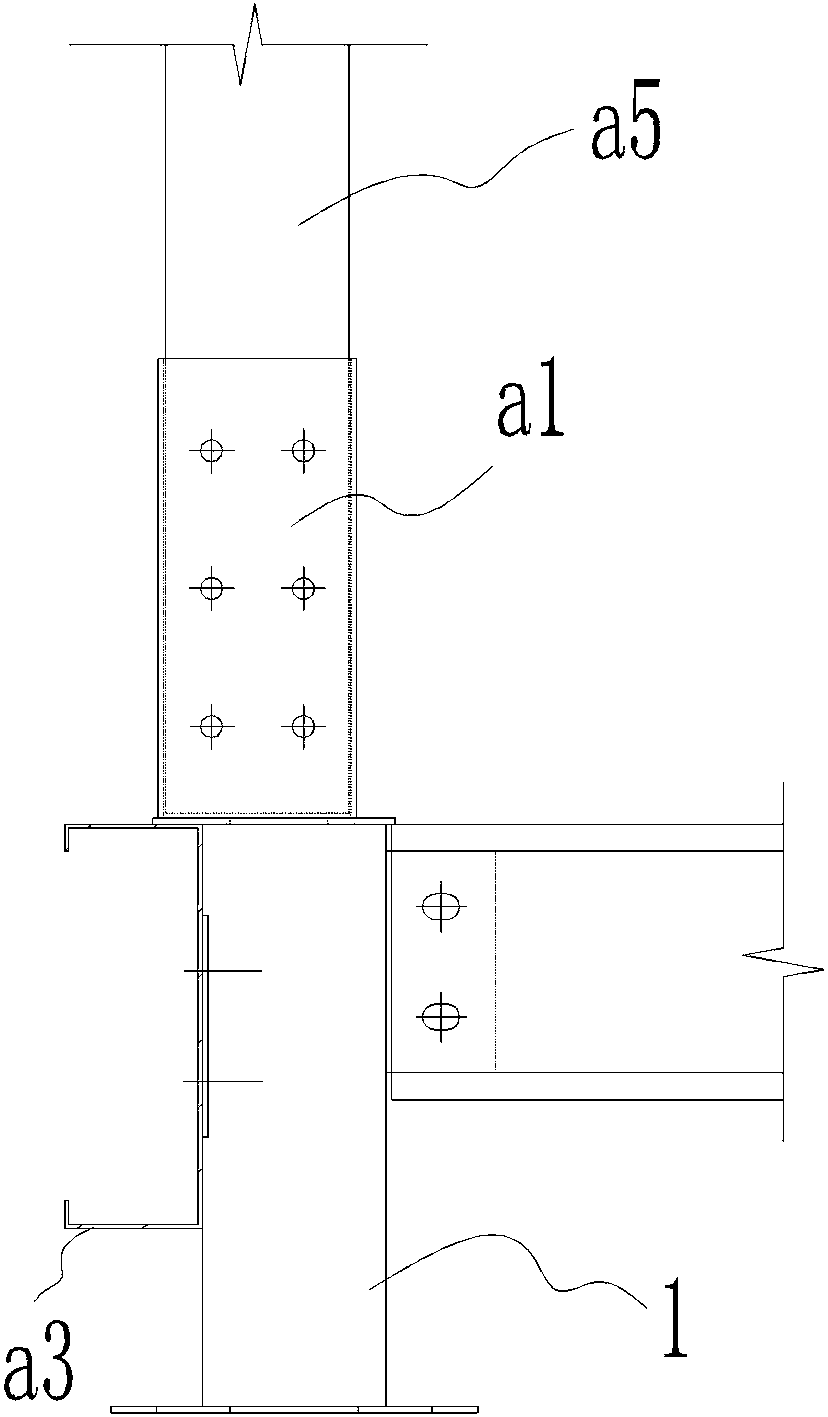

[0026] Embodiment: As shown in the figure, a new type of assembled column foot connection node:

[0027] It includes a bottom steel column and two galvanized C-shaped purlins. The two side walls of the bottom steel column are respectively provided with purlin connecting plates, and the two purlin connecting plates form a 90-degree angle distribution. The upper part of the purlin connecting plate The fixed connection has a pair of symmetrically distributed C-shaped hoops. The outer wall of the purlin connection plate is fixed to the galvanized C-shaped purlin, and the ends of the two galvanized C-shaped purlins form a 90-degree angle distribution. The upper part of the zinc C-shaped purlin is fixed with a U-shaped notch, and the upper steel column is inserted into the two C-shaped hoops, and the upwardly extending wall panel is inserted into the U-shaped notch, and the ends of the two wall panels Form a 90-degree angle distribution.

[0028] The galvanized C-shaped purlin is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com