Hybrid Mode Magnetorheological Isolators

A hybrid-mode, magneto-rheological technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of limiting the vibration isolation effect of the vibration isolation system, poor controllability, and increased space occupation. Achieve the effect of broadening the frequency range of vibration isolation, expanding the range of vibration isolation, and improving the range of vibration isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] When the present invention is describing the orientation, the figure 1 The orientation shown is described, and the upper and lower orientations in the figure are also up and down in the description; the description of the upper and lower orientations should not be used as a limitation to the present invention.

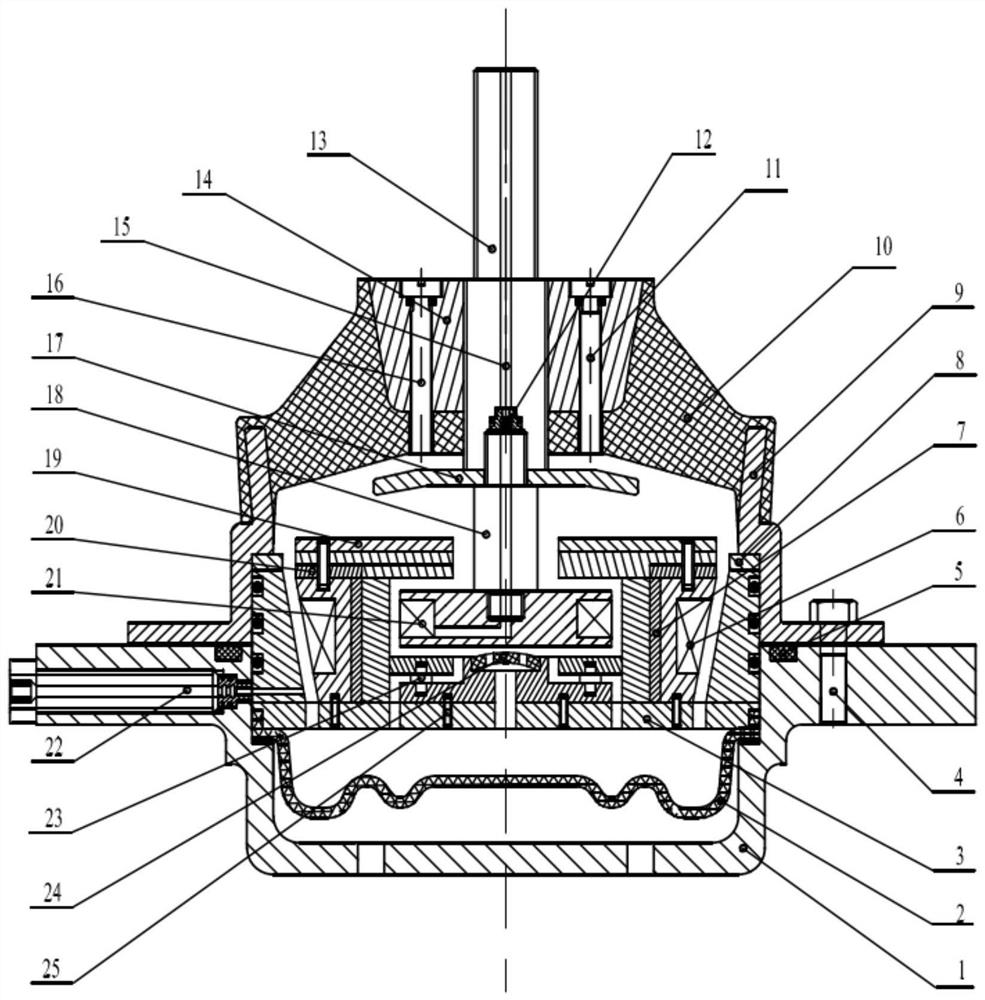

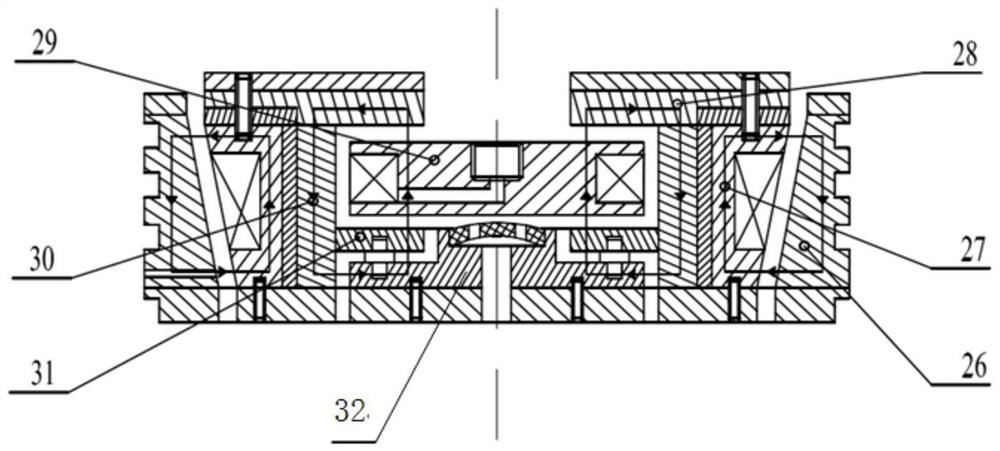

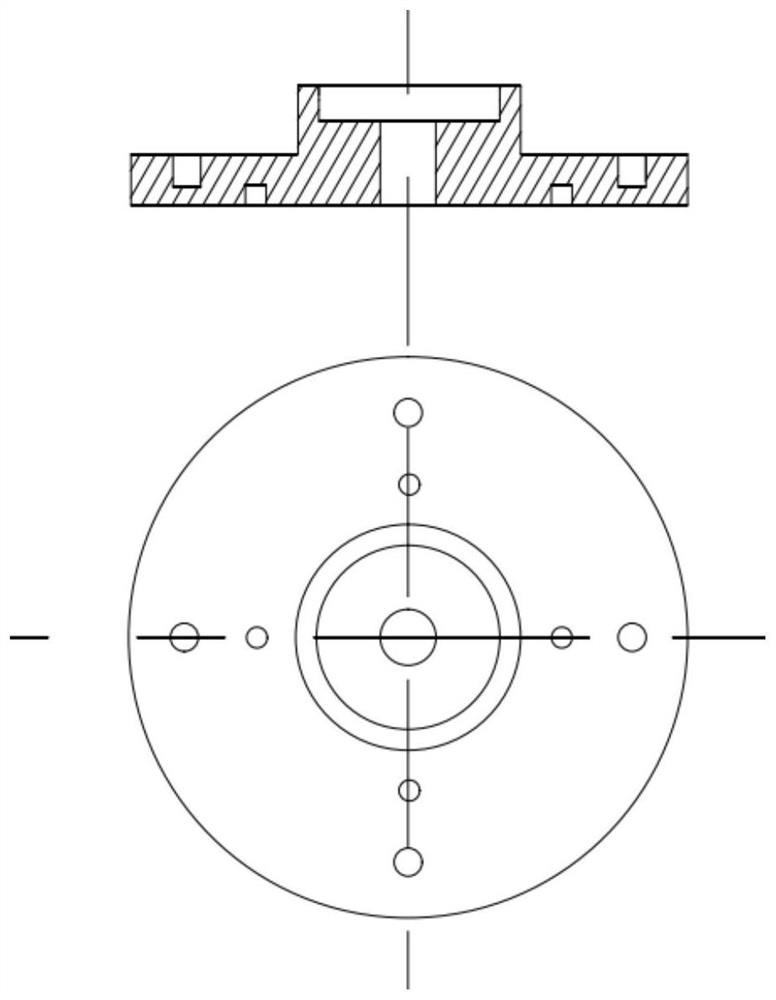

[0028] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the magnetic circuit of the present invention, image 3 It is a schematic diagram of the structure of the lower magnetic plate of the present invention, Figure 4 It is a schematic diagram of the structure seat of the magnetic isolation base of the present invention. As shown in the figure, the magneto-rheological vibration isolator of this embodiment includes an upper shell 9, a lower shell 1 that is fastened with the upper shell 9, and is arranged on the The damping assembly in the upper casing 9 and the lower casing 1; the fastening surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com