Air spring using double conical stack type auxiliary spring

A technology of auxiliary springs and air springs, applied in the direction of springs, spring/shock absorbers, shock absorber-spring combinations, etc., can solve the problems of limited vertical vibration damping effect, complex structure, cumbersome installation, etc., to ensure comfortable operation The effect of increasing the riding comfort and reducing the vertical stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

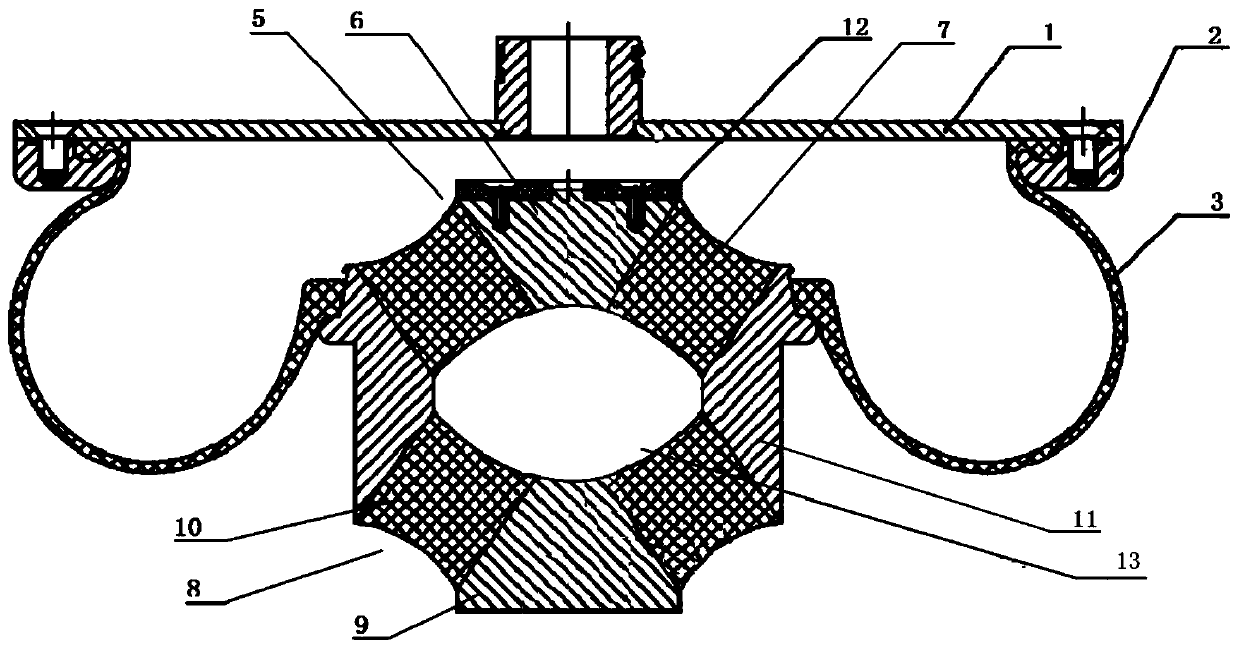

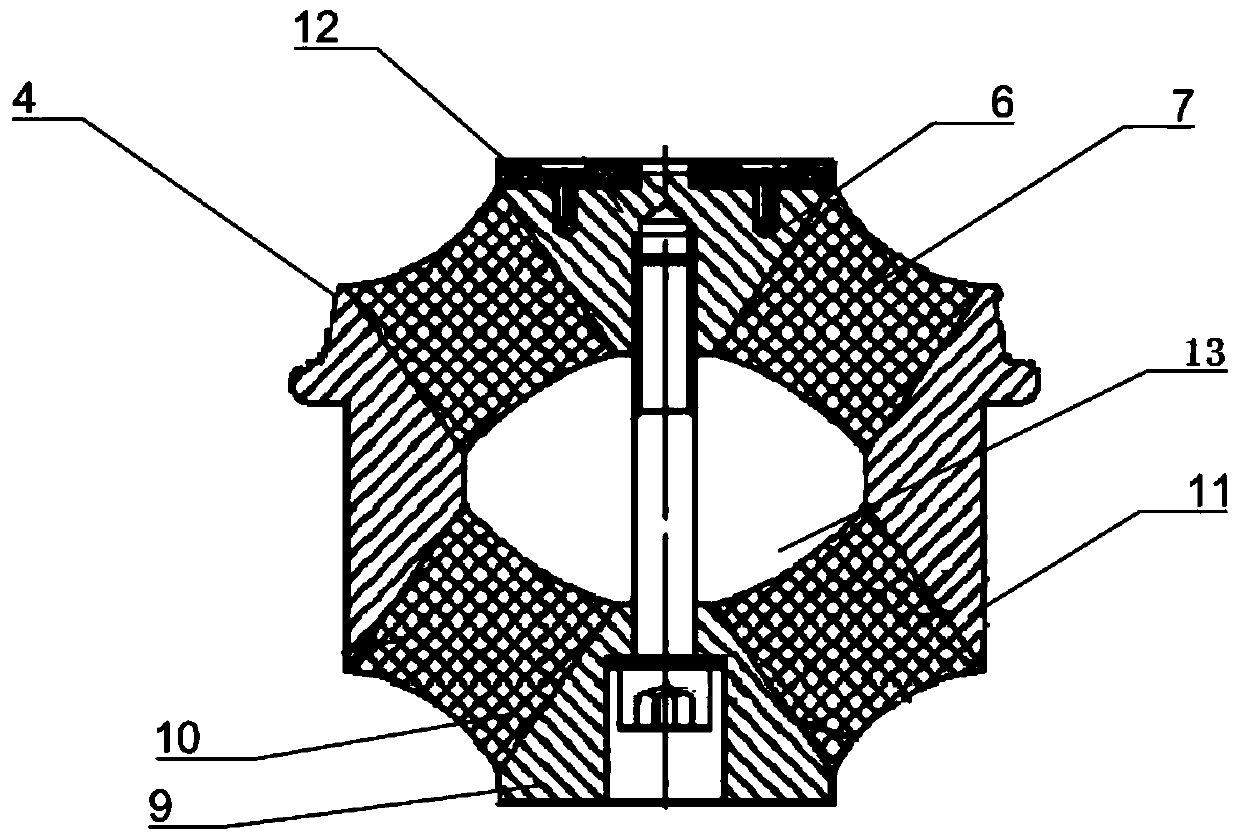

[0024] An air spring that uses a double-cone stack auxiliary spring, such as figure 1 As shown, the air spring system is mainly composed of an upper cover 1, a buckle 2, an air bag 3, an auxiliary spring 4, and a friction block 12. Wherein the auxiliary spring 4 includes an upper cone 5 , a lower cone 8 , and an outer jacket 11 . The upper mouth of the airbag 3 is press-fitted on the loam cake by the buckle 2 through screws, and the lower mouth of the airbag 3 is assembled with the outer coat layer 11 through interference fit. The upper cone 5 is vulcanized by the upper mandrel 6 and the upper rubber stack 7. In this implementation, the upper mandrel 6 is in the shape of a truncated cone, and its upper surface is fixedly connected with the friction block 12 by screws; the rubber stack can be selected There is no separator layer, and multiple separator layers can also be arranged at intervals inside the rubber pile. In this embodiment, it is preferred that there is no separato...

Embodiment 2

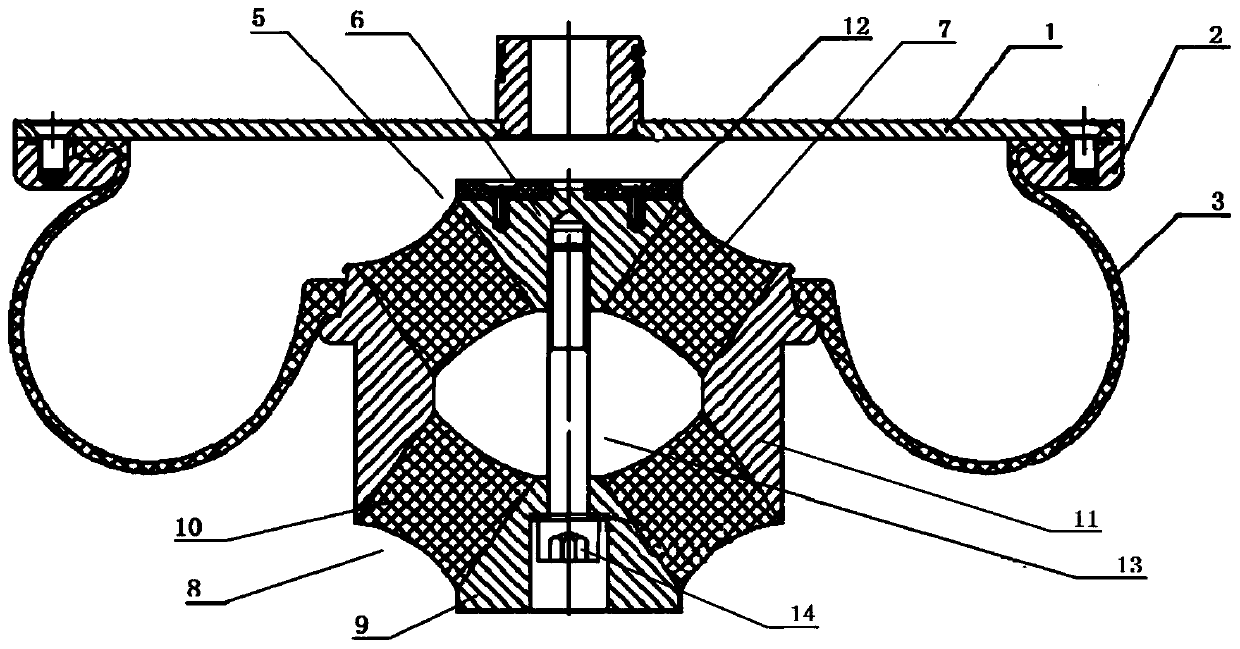

[0029] An air spring that uses a double-cone stack auxiliary spring, such as figure 2 As shown, its structure is different from that of Embodiment 1 in that a pre-tightening bolt 14 is installed at the central axis of the auxiliary spring 4, the pre-tightening bolt connects the upper mandrel 6 and the lower mandrel 9, and the top of the pre-tightening bolt 14 A spacer is placed on the upper surface, and the pre-tightening bolt 14 reduces the height drop of the air spring in an airless state, reduces the variation of the vertical stiffness, and further improves the situation that the vehicle body sinks and damages other components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com