Wheel rim for flywheel rotor and flywheel rotor

A flywheel rotor and rim technology, applied in flywheels, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problem that it is difficult to further increase the energy storage density of the flywheel rotor, the service life of the rim and the flywheel rotor is short, and the flywheel rotor is difficult to surpass. Rotation speed and other issues, to prevent radial delamination and splitting, low density, and increase speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

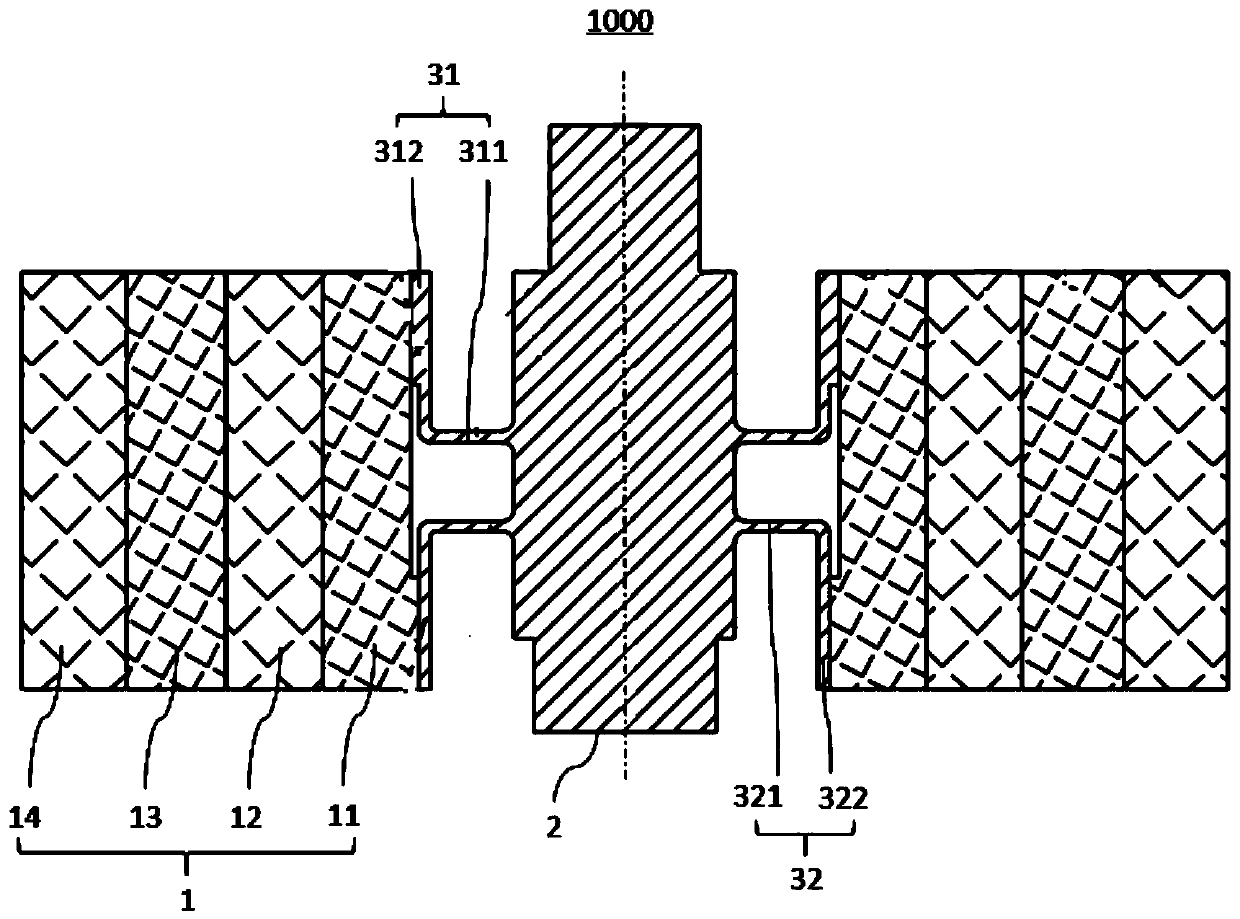

[0037] Refer below figure 1 A rim 1 for a flywheel rotor according to an embodiment of the first aspect of the present invention will be described.

[0038] Such as figure 1 As shown, according to the rim 1 used on the flywheel rotor 1000 according to the embodiment of the first aspect of the present invention, the rim 1 is hollow cylindrical, and the rim 1 is sequentially provided with multi-layer ring shapes on the radial projection plane from the inside to the outside. The fiber composite winding layer, the elastic modulus of the mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com