Internal threaded copper pipe for air conditioner

A technology of internal threads and copper tubes, which is applied in the field of internal threaded pipes of heat exchangers, can solve the problems of increasing the contact area between the inner wall of the copper tube and the refrigerant, accelerating the heat exchange efficiency of the refrigerant, and guiding the flow direction of the refrigerant, etc. Exchange performance, maintain heat exchange performance, avoid the effect of too close

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

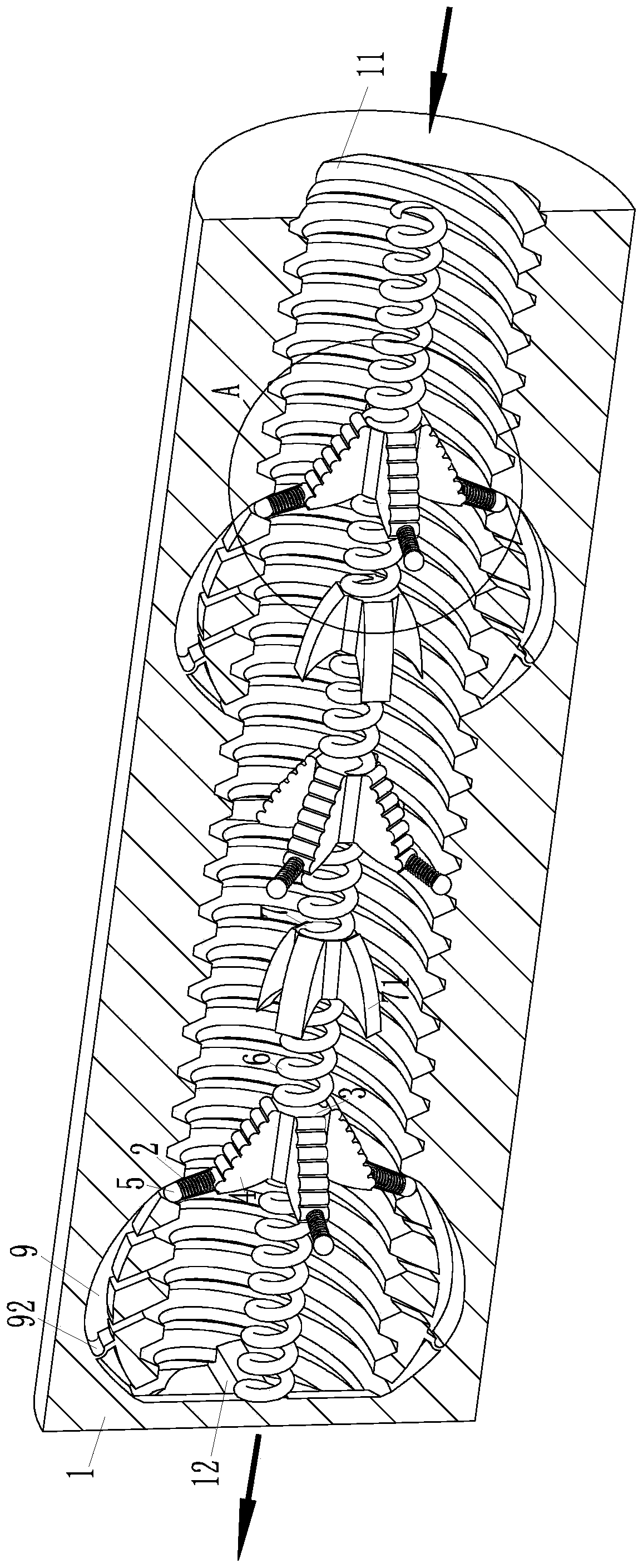

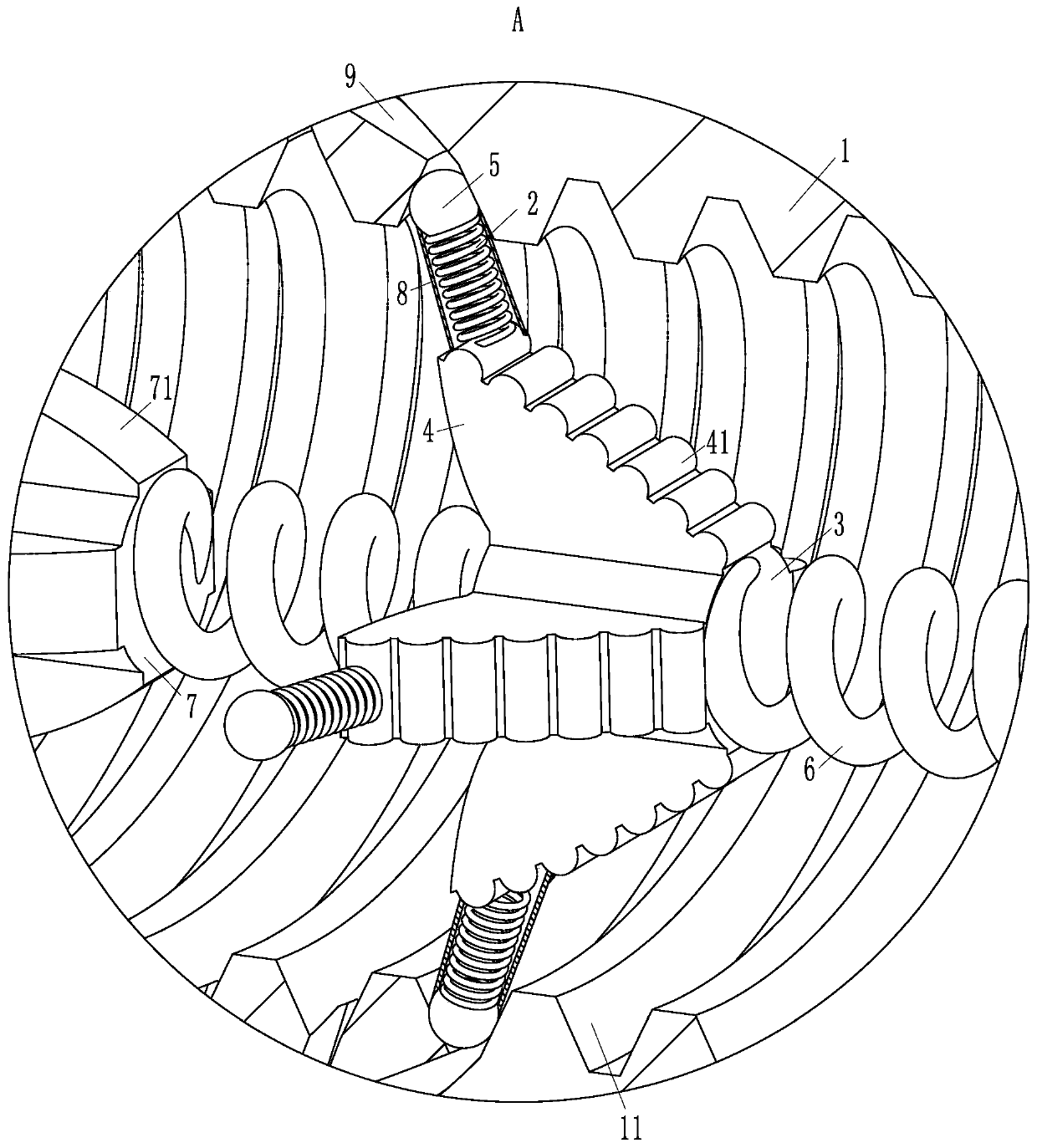

[0019] use Figure 1 to Figure 2 An internally threaded copper pipe for an air conditioner according to the present invention will be described as follows.

[0020] Such as Figure 1 to Figure 2As shown, a kind of internally threaded copper pipe for air conditioner of the present invention comprises copper pipe 1, No. 2 spring 2, cylindrical block 3 and water stirring plate 4; the inner surface of described copper pipe 1 is provided with internal thread 11; The cylindrical block 3 is located in the copper tube 1, the number of the cylindrical block 3 is at least three, and the axis of the cylindrical block 3 coincides with the axis of the copper tube 1; the circumferential direction of the cylindrical block 3 is uniformly provided with a water stirring plate 4; Two adjacent water stirring plates 4 are arranged in a staggered manner; the shape of the vertical section of the water stirring plate 4 is an obtuse triangle, and the top of the water stirring plate 4 is inclined to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com