Flexible angle sensor and preparation method thereof

An angle sensor, flexible technology, applied in the direction of instruments, measuring devices, measuring force, etc., can solve the problems of complex sensor preparation process, low sensing performance, high price, etc., and achieve easy large-scale production, simple preparation process, high The effect of angle-aware sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

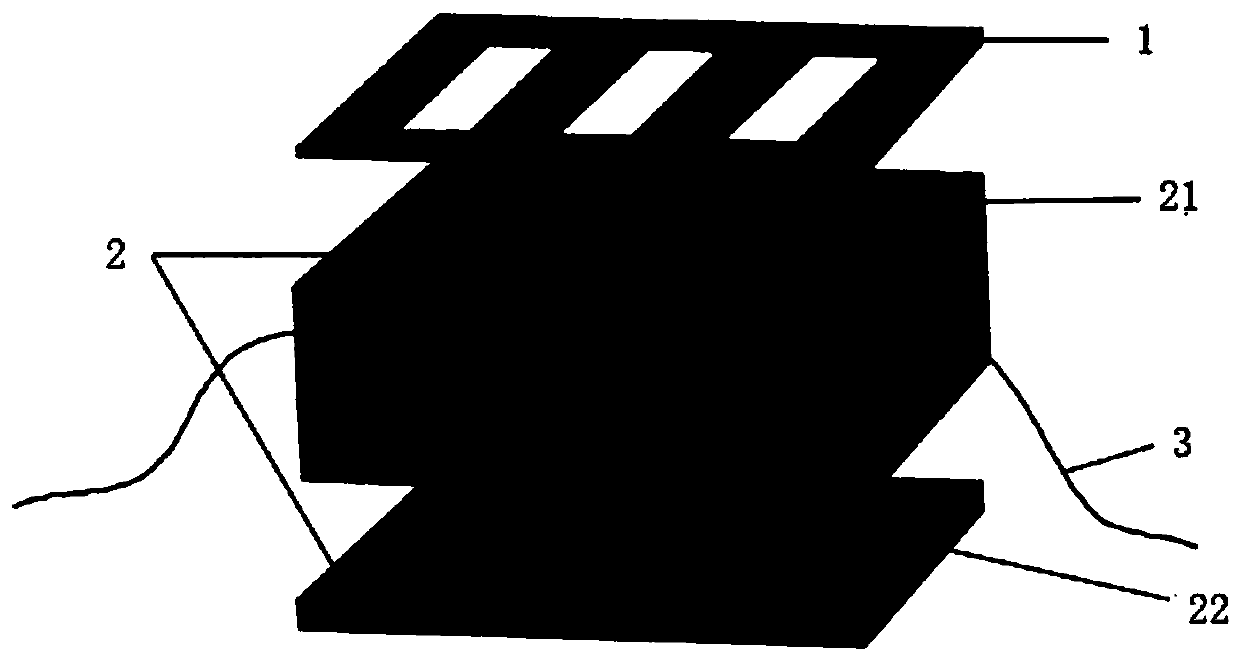

[0025] A preparation method of a flexible angle sensor, comprising the following steps:

[0026] a. Preparation of conductive dispersion: 0.05 g of multi-walled carbon nanotubes and 0.1 g of sodium dodecylbenzenesulfonate surfactant were prepared into 50 ml of aqueous dispersion, and stirred at 30° C. and 300 r / min for 1 hour;

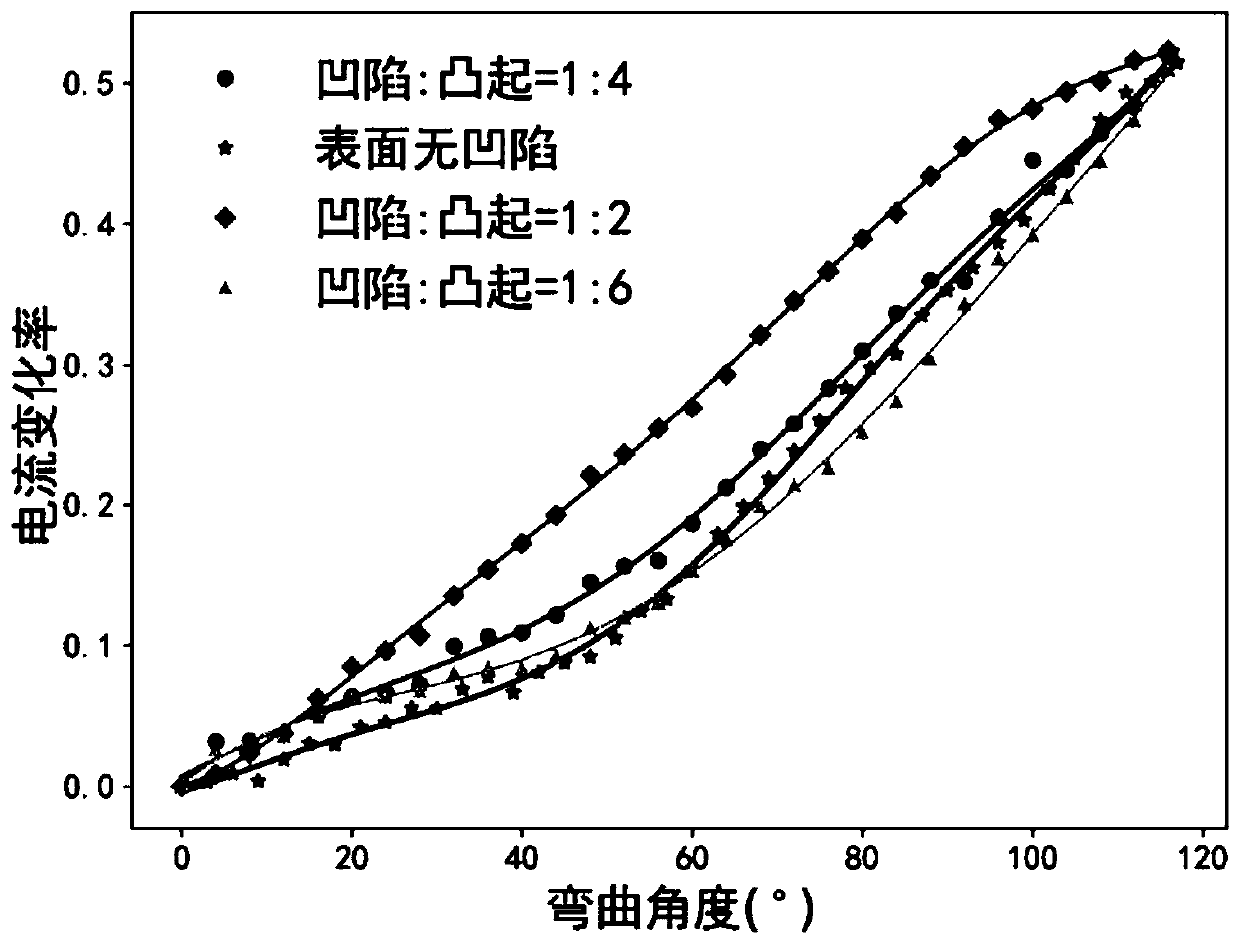

[0027] b. Preparation of porous sponge with concave-convex arrangement: use a drawing tool to draw a mask template with a rectangular concave-convex structure, use the mask template to engrave a surface microstructure with concave-convex arrangement on the polyurethane porous sponge, the engraving power is 30W, and the speed is 10mm / s, the precision is 500ppi, and the aspect ratio of the concave-convex structure is 1:4;

[0028] c. Preparation of porous conductive sponge layer with concavo-convex arrangement: immerse the polyurethane porous sponge with concavo-convex structure obtained in step b into the multi-walled carbon nanotube dispersion prepare...

Embodiment 2

[0032] A preparation method of a flexible angle sensor, comprising the following steps:

[0033] a. Preparation of conductive dispersion: 0.5 g of graphene and 1 g of sodium dodecylbenzenesulfonate surfactant were prepared into 100 ml of aqueous dispersion, stirred at 60° C. and 600 r / min for 2 hours;

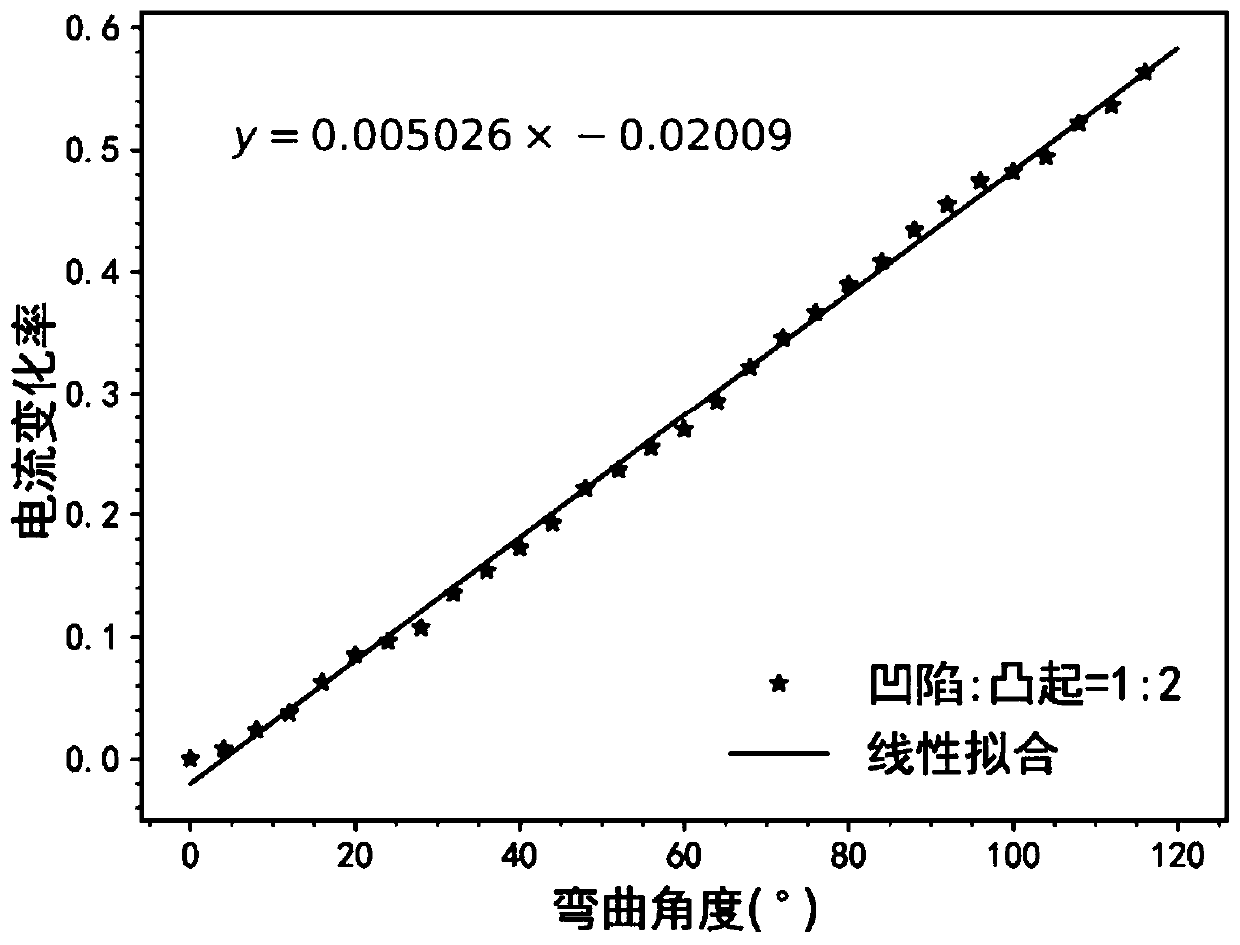

[0034] b. Preparation of porous sponge with concave-convex arrangement: use a drawing tool to draw a mask template with a zigzag concave-convex structure, use the mask template to engrave a surface microstructure with concave-convex arrangement on the porous polyvinyl alcohol sponge, and the engraving power is 60W. The speed is 55mm / s, the precision is 500ppi, and the aspect ratio of the concave-convex structure is 1:2;

[0035] c. Preparation of porous conductive sponge layer with concavo-convex arrangement: immerse the porous sponge with concavo-convex structure obtained in step b into the graphene dispersion prepared in step a, dry it in a constant temperature drying oven fo...

Embodiment 3

[0039] A preparation method of a flexible angle sensor, comprising the following steps:

[0040] a. Preparation of conductive dispersion: 0.28g of single-walled carbon nanotubes and 0.5g of sodium dodecylbenzenesulfonate surfactant were formulated into 75ml of aqueous dispersion, and stirred at 45°C and 450r / min for 1.5 hours;

[0041] B, the preparation of the porous sponge of concavo-convex arrangement: utilize drawing tool to draw the mask template that has rectangular concavo-convex structure, utilize this mask template to engrave the surface microstructure of concavo-convex arrangement on the porous seaweed cotton sponge, the power of engraving is 45W, and the speed is 30mm / s, the precision is 500ppi, and the aspect ratio of the concave-convex structure is 1:6;

[0042]c. Preparation of porous conductive sponge layer with concave-convex arrangement: immerse the porous seaweed cotton sponge with concave-convex structure obtained in step b into the single-walled carbon nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com