Shell assembly, preparation method thereof and electronic equipment

A shell assembly and shell technology, which is applied to electrical equipment shells/cabinets/drawers, electronic equipment, casings/cabinets/drawer parts, etc., can solve problems such as wrinkles, poor fit, and needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

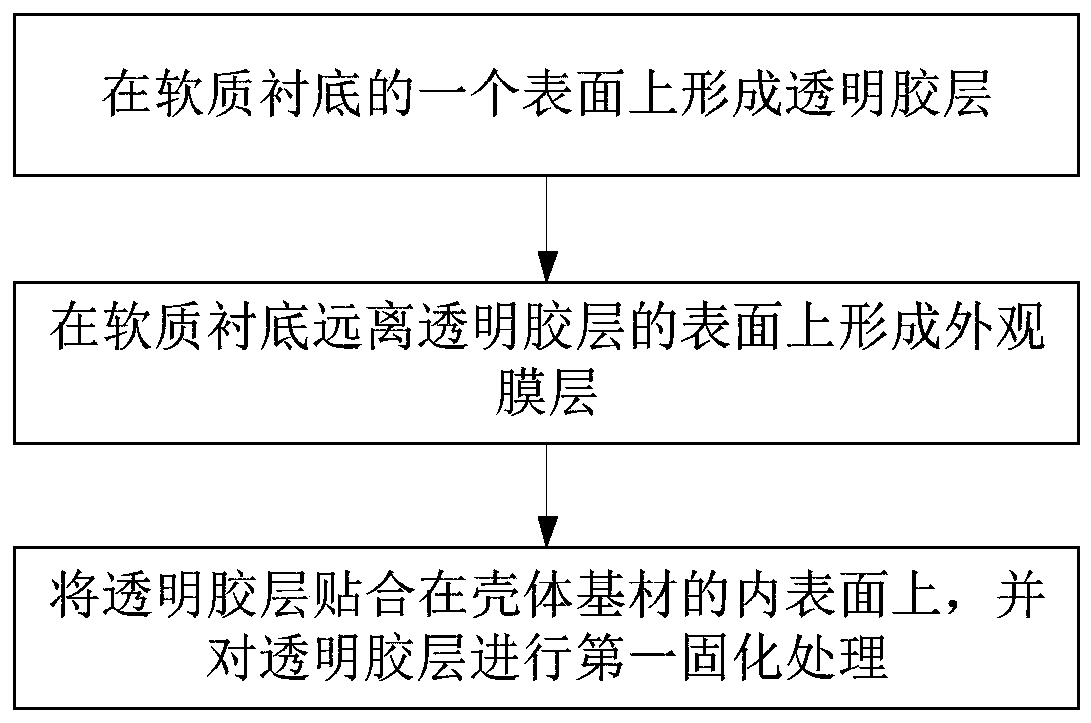

Method used

Image

Examples

Embodiment 1

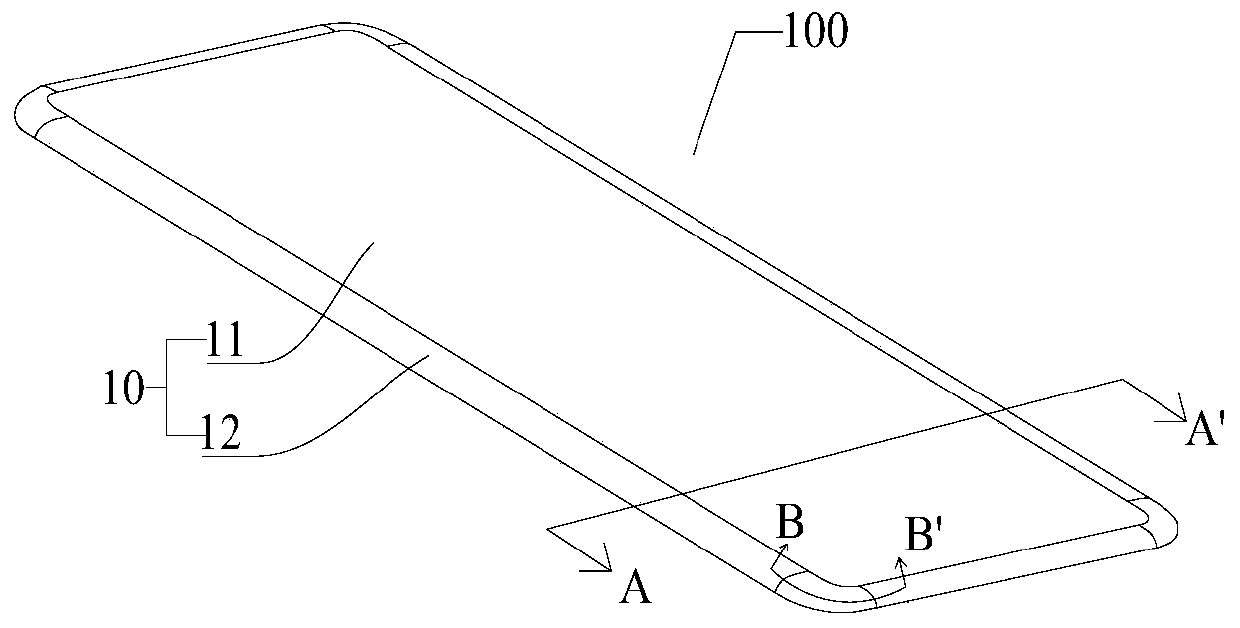

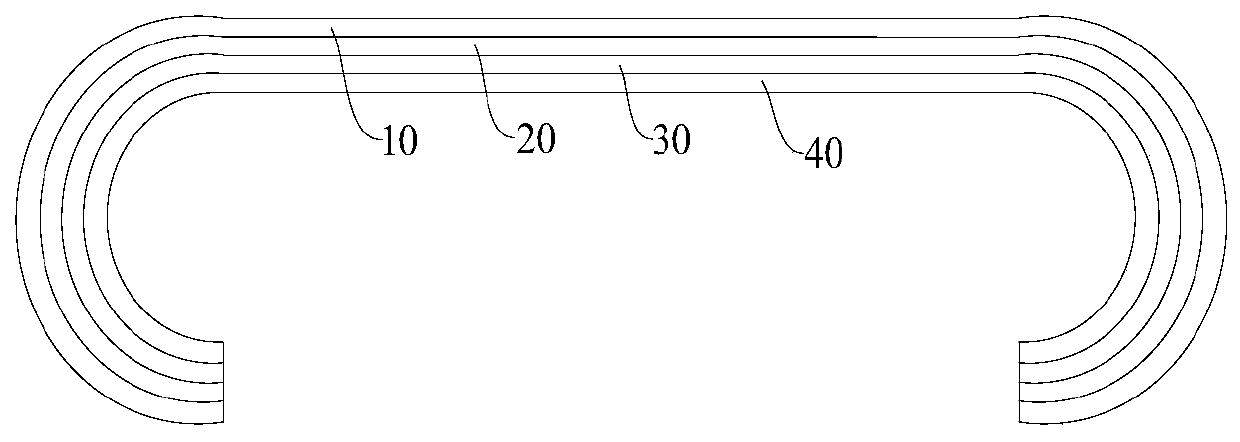

[0039] Heat the PUR hot melt adhesive to a molten state, and unwind the TPU soft film layer roll with a thickness of 100 microns through traction, and use a roller doctor blade to apply the molten liquid PUR hot melt adhesive on the surface through slit extrusion. On the TPU soft film layer, control the coating thickness to 20-30 microns, and quickly cool the coated glue into a solid to obtain a transparent adhesive layer, and finally wind it into a roll material. During this process, the glue does not react, and the transparent adhesive layer The kinetic friction coefficient of the surface is less than 0.5. Then, on the surface of the soft film layer away from the transparent adhesive layer, a UV transfer layer, a PVD coating layer, and an ink cover layer are sequentially formed, and then the above-mentioned product is cut into the same size as the shell substrate, and the shell is positioned by the CCD The base material and the product obtained above are covered with an isol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com