Vacuum pressure stabilizing tank for rotating-disc-type milking machine

A milking machine and turntable technology, which is applied in the field of pressure-stabilizing tanks, can solve problems such as vacuum pump starter motor burnout, vacuum pump inner wall space being filled, and milking machines unable to milk milk, etc., so as to reduce production costs and improve production Efficiency, ingenious structure and unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

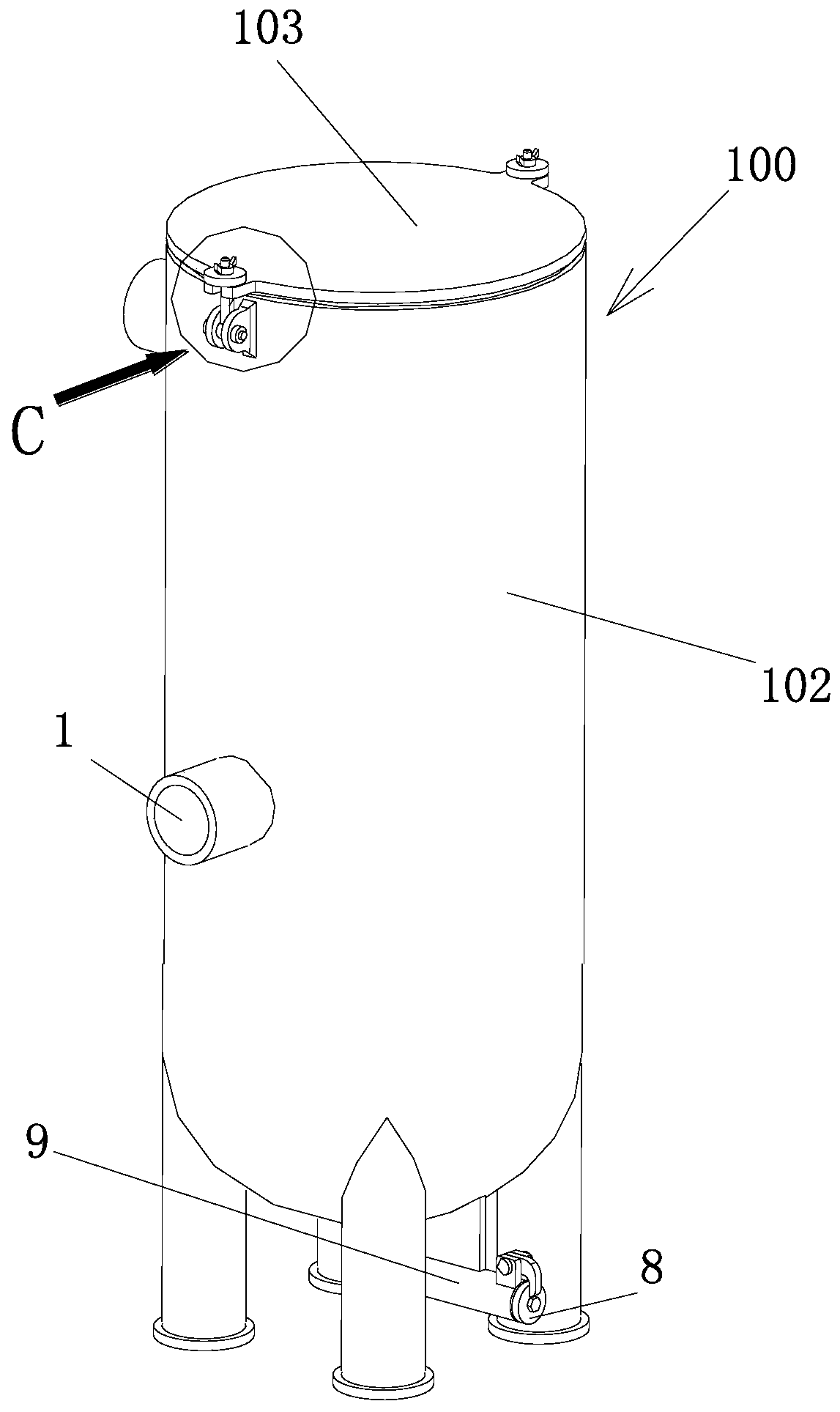

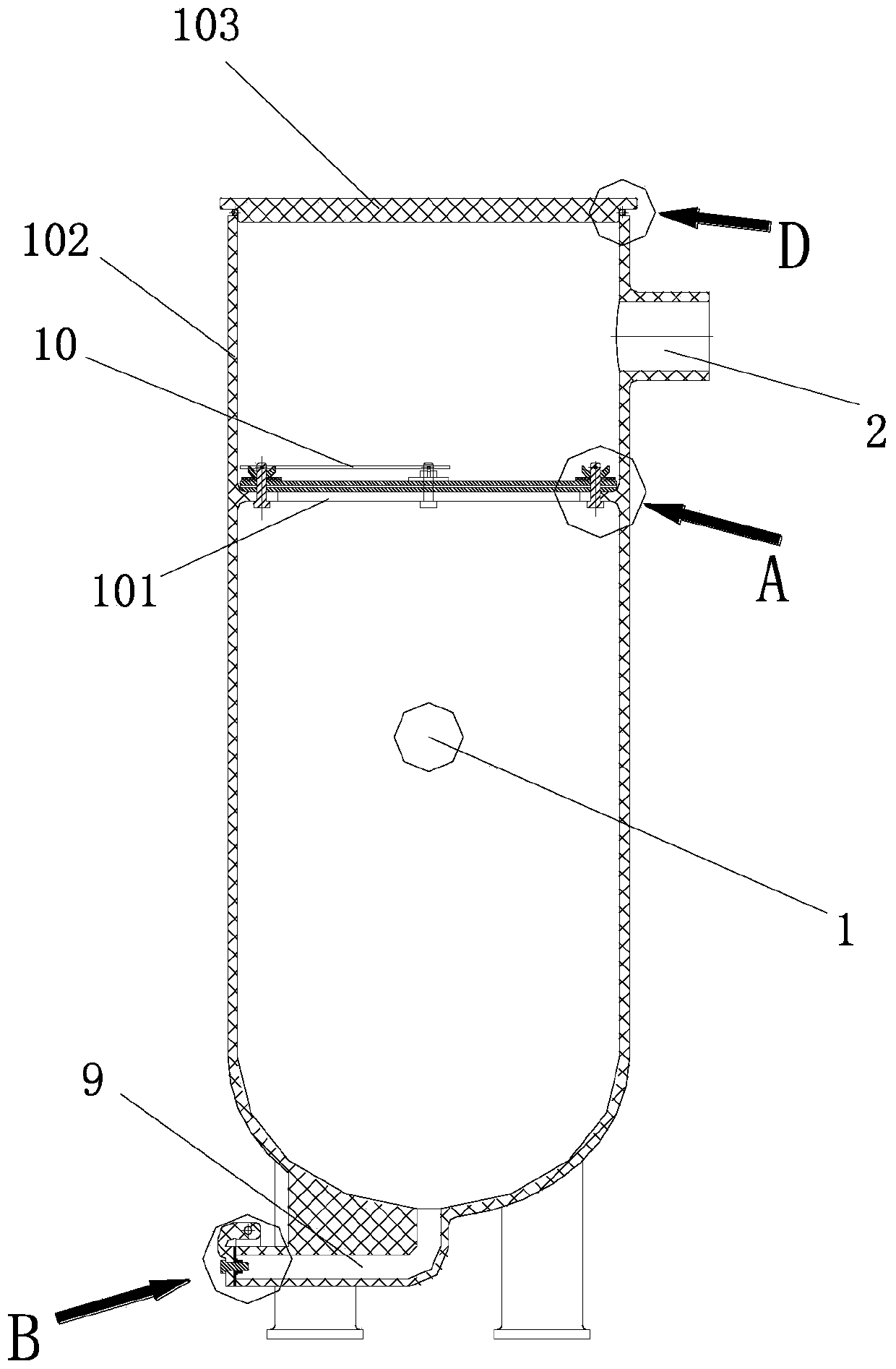

[0037] figure 1 , figure 2 Shown is a vacuum surge tank for a rotary milking machine, comprising a tank body 100, provided with an air inlet 1 and an air outlet 2, and the tank between the air inlet 1 and the air outlet 2 A set of filter assemblies are arranged on the inner wall of the body 100, and the filter assemblies include a detachably fixed filter membrane 3 (a piece of filter cotton), between the edge of the filter membrane 3 and the inner wall of the tank body 100 The airtight connection is maintained so that the gas entering from the air inlet 1 must be filtered by the filter membrane 3 before being output from the air outlet 2 .

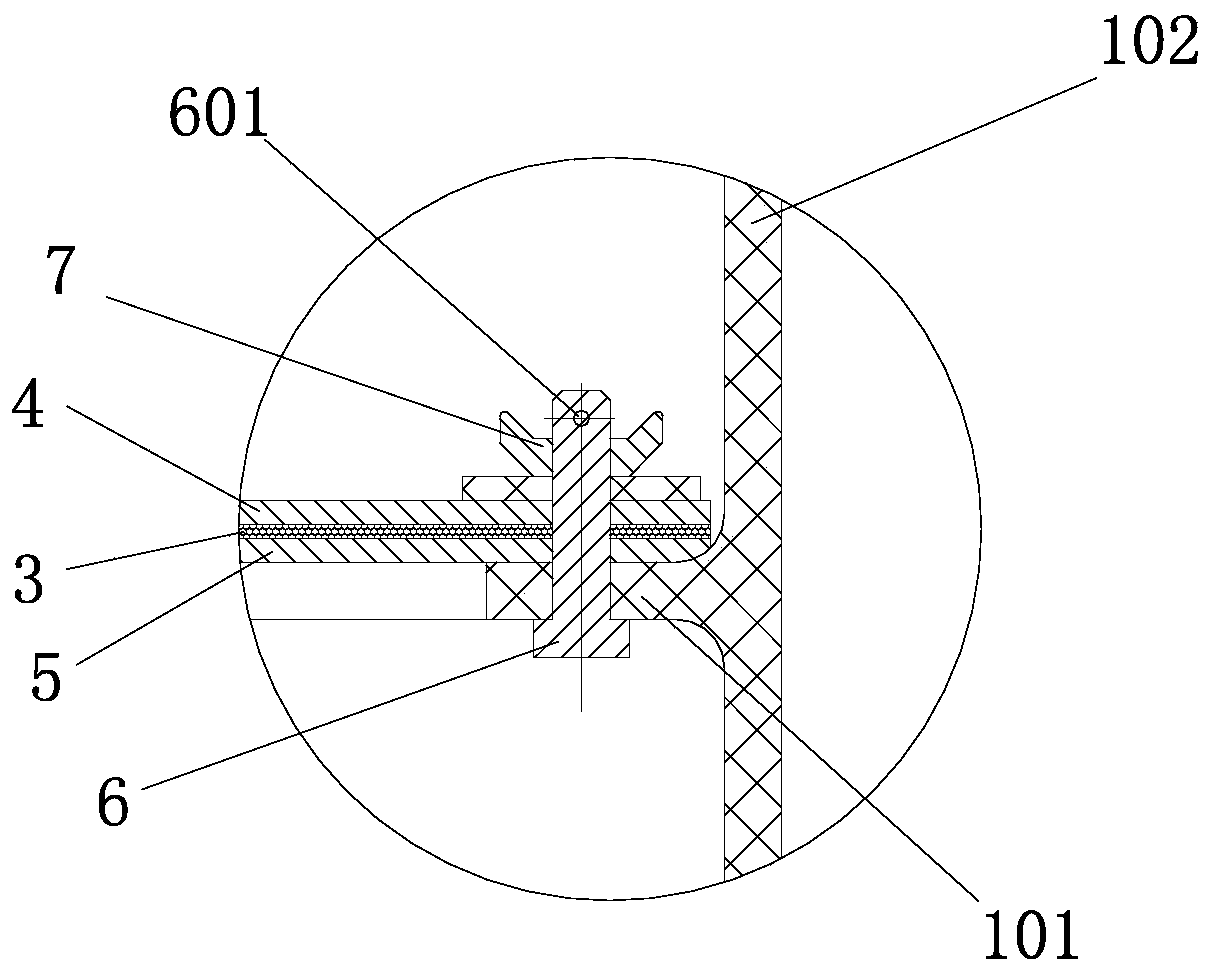

[0038] Such as image 3 As shown, the filter assembly includes a first filter membrane clamping net 4 and a second filter membrane clamping net 5 detachably fixed by screws and nuts, respectively clamped on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com