An automatic access system for medical maintenance tools

A technology for accessing systems and maintenance tools, applied in the field of tool storage equipment, can solve the problems of simplicity and rudeness, constant storage space, and inability to count tool usage, etc., and achieves the effect of various storage forms and properly standardized storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

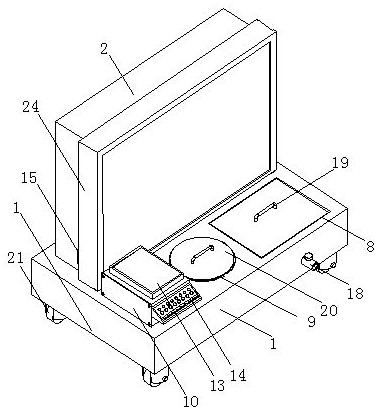

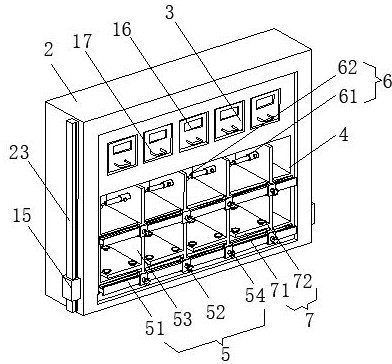

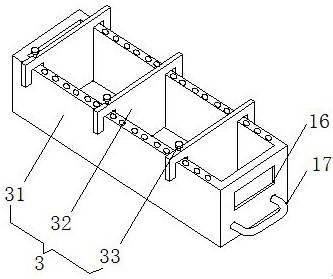

[0025]An automatic access system for medical maintenance tools, including a base plate 1, an access box 2 is provided on the rear side of the upper end of the base plate 1 to realize the storage of tools, and a storage structure is provided in the installation slots evenly distributed on the upper end of the front side of the access box 2 3. The storage structure 3 includes a drawer 31 that is slidably connected in the installation groove to realize tool storage. The two sides of the upper end of the drawer 31 are slidably connected to the chute at the bottom of the partition 32. The upper end of the partition 32 is provided with an adjusting bolt 33 for adjusting The bottom end of bolt 33 is threadedly connected with the evenly distributed threaded holes on both sides of the drawer 31. The front side of drawer 31 in storage structure 3 is provided with numbering plate 16 and handle 17 successively from top to bottom. There are two evenly distributed access slots 4, the bottom ...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is:

[0028] In this embodiment, the size adjustment structure 5 includes a track 51 arranged at the bottom edge of the front side of the access slot 4, and the upper end of the track 51 is slidably connected with evenly distributed sliders 52, and the upper end of the slider 52 is provided with a partition plate 53 , the rear end of the partition plate 53 extends to the inside of the access slot 4, the front side of the slider 52 is screwed with a locking bolt 54, the inner end of the locking bolt 54 contacts the front surface of the track 51, and the suspension structure 6 Comprising a telescopic column 61 fixedly connected to the left side wall of the partition plate 53 above, the left part of the telescopic end of the telescopic column 61 is provided with a hook 62, and the adsorption structure 7 includes a pendulum fixedly connected to the bottom left side of the partition plate 53 below. Put plate 71, put the...

Embodiment 3

[0031] The difference between this embodiment and Embodiment 1 is:

[0032] In this embodiment, the cleaning device 8 includes a bracket 81 fixedly connected to the inner wall of the mounting groove at the right end of the base plate 1, the bottom end of the bracket 81 is fixedly connected to the center of the upper end of the disc 82, and the chute on the arc surface of the disc 82 is connected to the ring plate The annular slider at the bottom of 83 is slidingly connected, the inner wall of the ring plate 83 is covered with brush strips 86, the bottom of the base plate 1 is provided with a servo motor 84, and the output shaft of the servo motor 84 passes through the bottom through hole of the base plate 1 and extends to In the installation groove, the top of the output shaft of the servo motor 84 is provided with three evenly distributed diagonal braces 85, the top of the diagonal braces 85 is fixedly connected to the bottom surface of the ring plate 83, and the input end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com