Crawler assembly unit and crawler assembly

A technology for assembling units and tracks, which is used in tracked vehicles, transportation and packaging, motor vehicles, etc., can solve the problems of poor working conditions of excavators, falling off track shoes, breaking track bolts, etc., so as to reduce lateral shear and torsion. The effect of force, preventing breakage and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

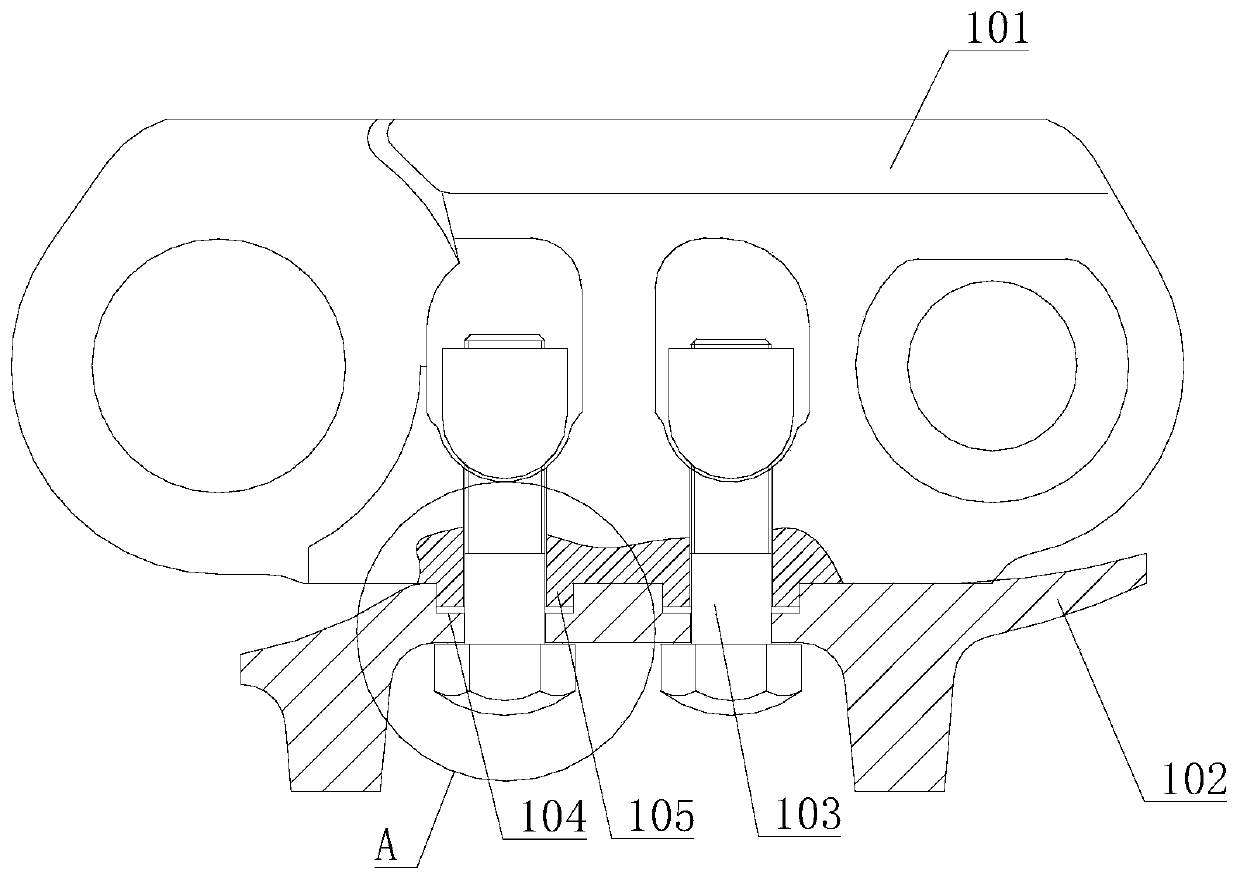

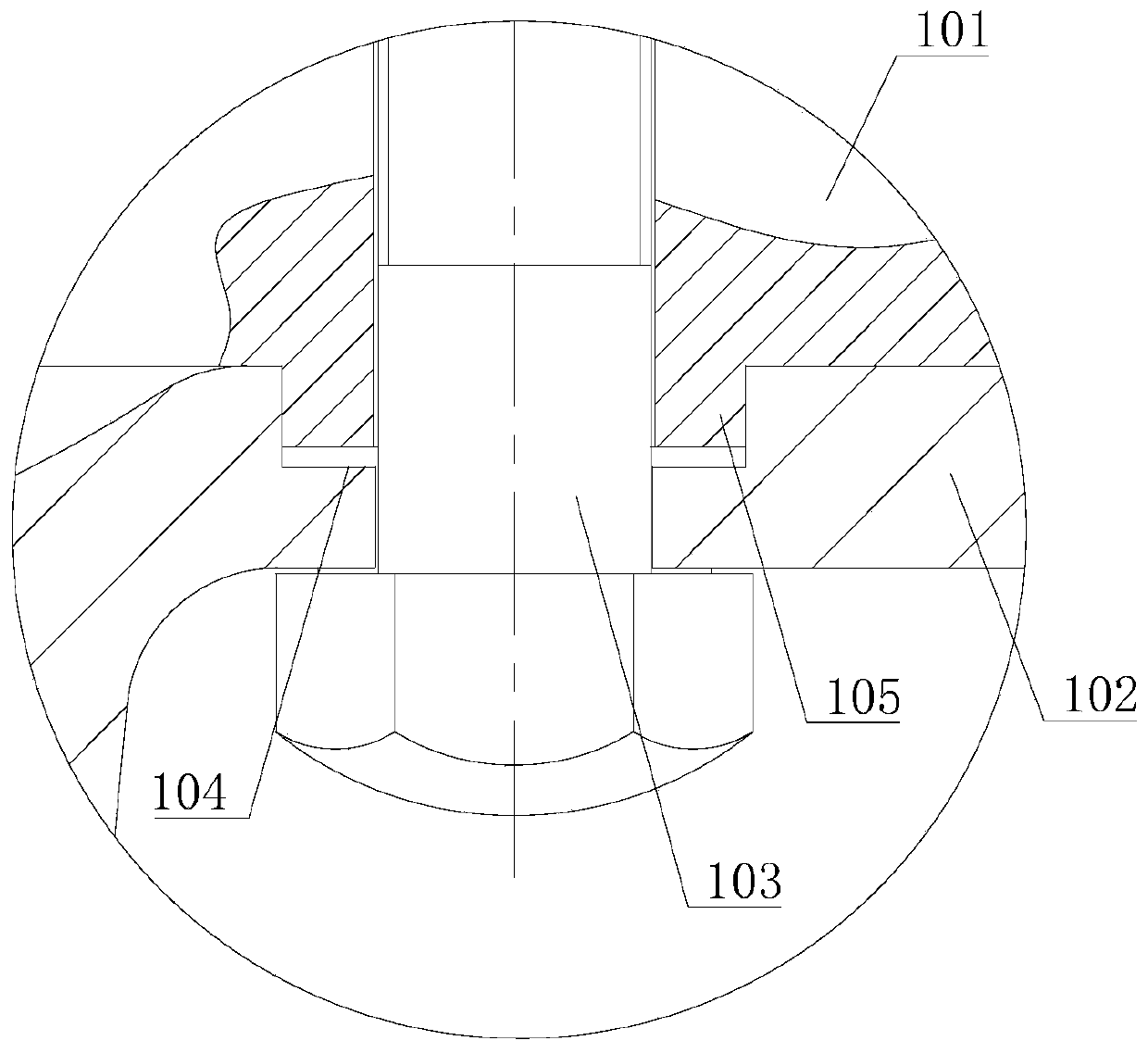

[0038] see Figure 1 to Figure 4 As shown, the track assembly unit provided by the present application includes a chain rail link group 101, a track shoe 102 and a connector 103; the chain rail link group 101 and the track shoe 102 are connected through the connector 103; the track shoe 102 is provided with The positioning groove 104 and the chain rail segment group 101 are provided with a positioning protrusion 105 , and the positioning protrusion 105 can be inserted into the positioning groove 104 for positioning the relative positions of the chain rail segment group 101 and the track shoe 102 .

[0039]Specifically, the crawler assembly unit includes a chain rail link group 101 , a crawler shoe 102 and a connecting piece 103 . Among them, the chain rail link group 101 is the most important part of the crawler belt, which plays the role of supporting weight and transmitting driving force; The effect of force; the chain rail segment group 101 and the track shoe 102 are attac...

Embodiment 2

[0051] The second embodiment is an improvement on the basis of the above embodiment, and the technical content disclosed in the above embodiment will not be described repeatedly, and the content disclosed in the above embodiment also belongs to the content disclosed in the second embodiment.

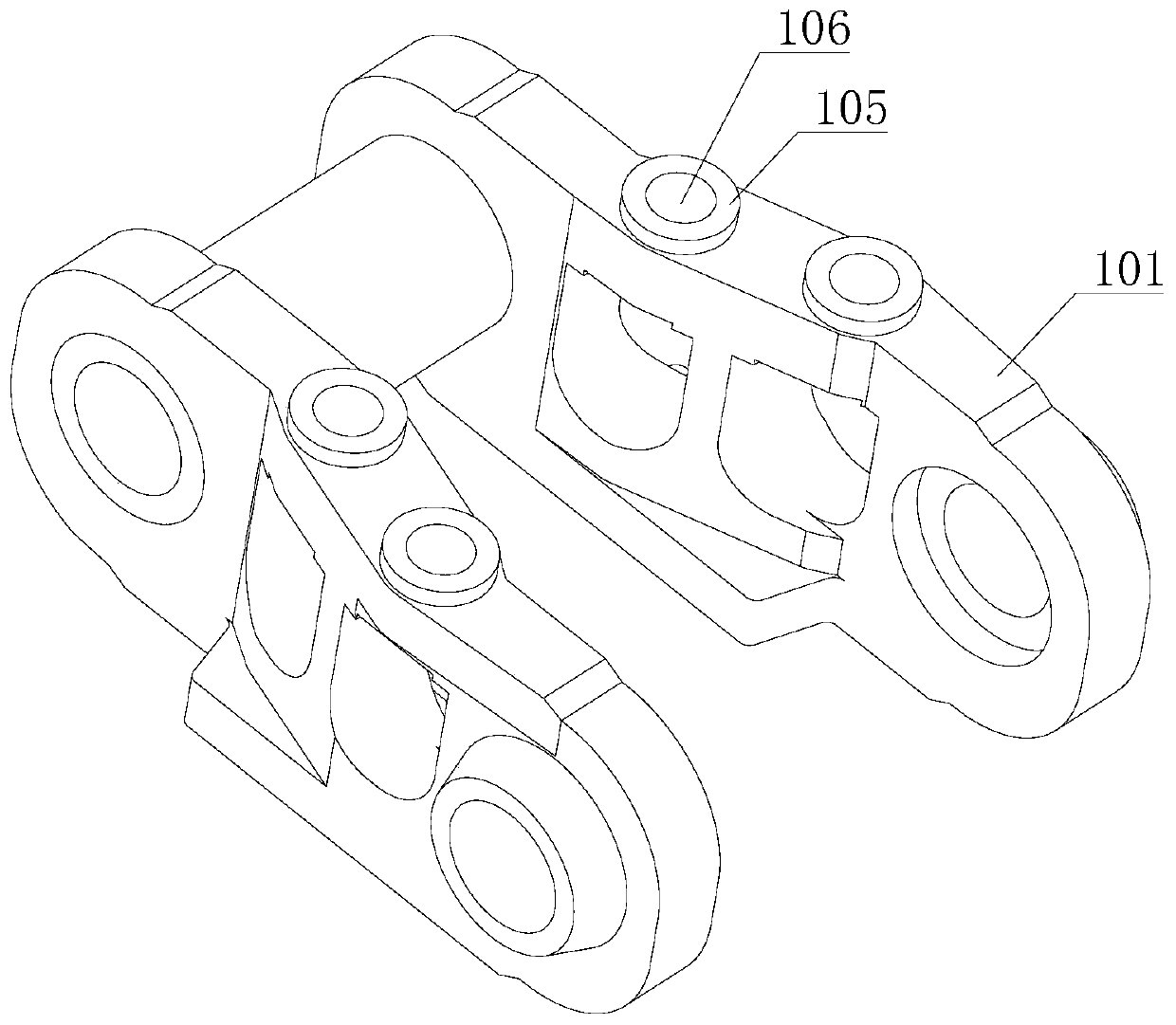

[0052] see Figure 5 As shown, in the optional case of this embodiment, the chain rail section group 101 includes a first chain rail section 108 and a second chain rail section 109; the first chain rail section 108 and the second chain rail section 109 are symmetrically arranged, and the first chain rail section 109 Both the chain rail segment 108 and the second chain rail segment 109 are connected to the track shoe 102 .

[0053] In this embodiment, the first chain rail link 108 and the second chain rail link 109 are arranged symmetrically on the track shoe 102, so that the force of the whole structure is more balanced.

[0054] In the optional solution of this embodiment, the chain ra...

Embodiment 3

[0057] Embodiment 3 of the present application provides a crawler belt assembly, including a plurality of crawler belt assembly units in any one of the above embodiments, and multiple crawler belt assembly units are connected in sequence, see Image 6 As shown, for the convenience of expression, only the schematic diagram of the connection between two crawler assembly units is shown in the figure, and the connection methods of other crawler assembly units are the same. The crawler belt assembly has all the beneficial technical effects of the crawler belt assembly unit in any of the above embodiments, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com