Construction system and construction method of composite wallboard

A technology of composite wall panels and sandwich panels, applied in building components, buildings, building structures, etc., can solve the problems of inability to ensure the consistency and accuracy of solder joints, increase construction costs, wall stability and strength decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

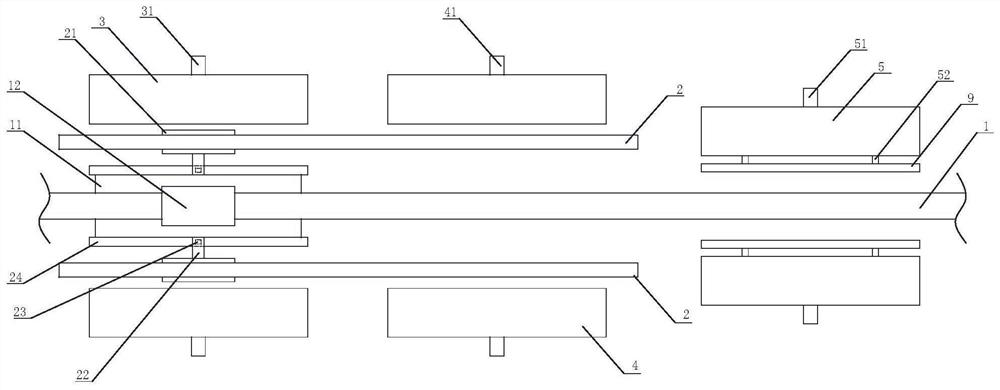

[0069] Such as Figure 1 to Figure 8 The construction system of a composite wallboard shown includes a mounting frame 24, a placing unit 3, a nailing unit 4 and a hanging net unit 5, wherein:

[0070] The mounting frame 24 is used to load the hanging net carrying mechanism 7, and drives the hanging net carrying mechanism 7 on both sides of the sandwich panel to move synchronously with the sandwich panel to the placing unit 3 and the nail shooting unit 4;

[0071] The placement unit 3 is used to send the hanging net carrying mechanism 7 into the mounting racks 24 on both sides of the sandwich panel;

[0072] The nail-shooting unit 4 is used to spray the abdominal nails 8 to the hanging net loading mechanism 7 in the mounting frame 24 on one side of the sandwich panel, and the abdominal nails 8 penetrate the sandwich panel and are fixedly connected to the hanging net loading on both sides of the sandwich panel. Agency 7;

[0073] The hanging net unit 5 is used to clamp the ste...

Embodiment 2

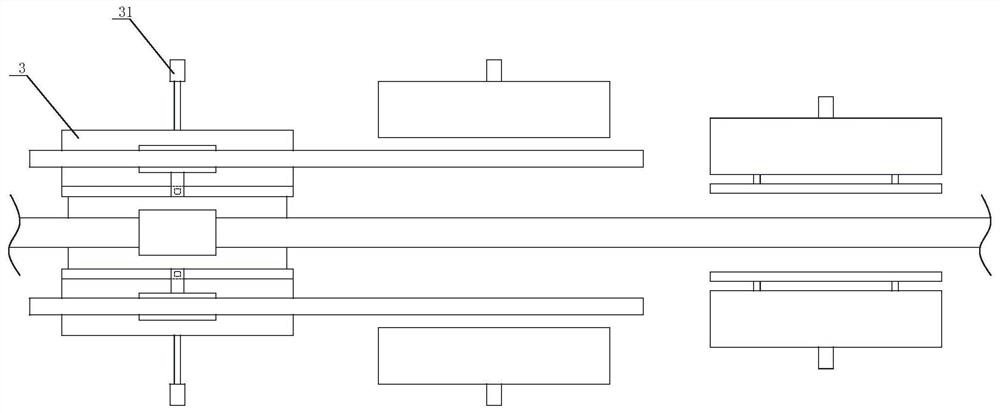

[0082] On the basis of Example 1, such as Figure 5 As shown, the placement unit 3 is provided with a fourth driving device 33, the output end of the fourth driving device 33 is connected with a box sending part 35, and a lower box bucket 34 is arranged above the box sending part, and the lower box bucket 34 is used to store the hanging net carrying mechanism 7 and drop the hanging net carrying mechanism 7 onto the pushing path of the box delivery part 35 one by one, and the box sending part 35 pushes the hanging net carrying mechanism 7 on the pushing path into the mounting frame 24 superior.

[0083] In some embodiments, the placement unit is provided with several first partitions 32, and the first partition divides the placement unit into several placement areas, and each placement area is provided with a fourth driving device, a box feeder and Out of the box opening 36, the box out of the mouth and the chamber corresponding to each other, so as to push the hanging net car...

Embodiment 3

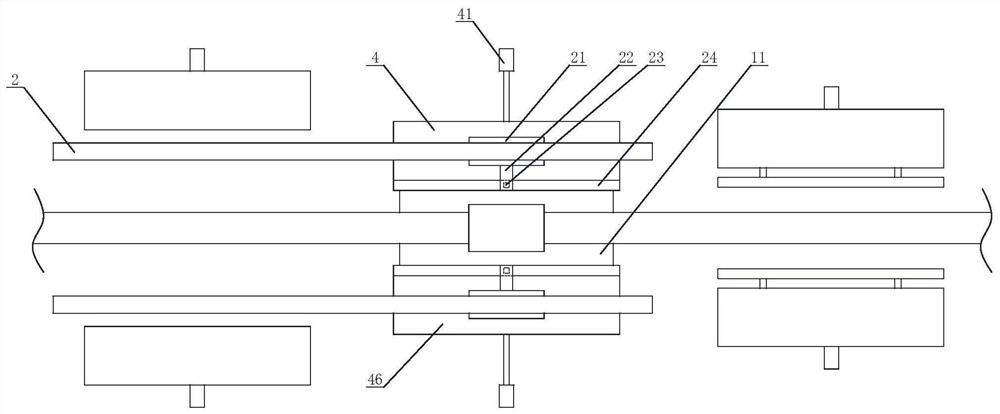

[0088] On the basis of the above examples, if Figure 6 As shown, the nail shooting unit 4 is provided with a nail gun 43, and the nail gun 43 is used to spray the abdominal nails 8 in the nail shooting unit 4 into the hanging net on the mounting frame 24 on one side of the sandwich panel. In the carrying mechanism 7, the abdominal nail 8 penetrates the sandwich panel and is inserted into the hanging net carrying mechanism 7 on the mounting frame 24 on the other side of the sandwich panel, and the spray path of the nail gun 43 is provided with a stabilizer 44, the stabilizer 44 is used to fix the abdominal nail 8 and adjust the firing angle of the abdominal nail 8.

[0089] In some embodiments, such as Figure 6 As shown, the nail shooting unit is provided with several second partitions 42, and the second partition divides the nail shooting unit into several nail shooting areas, and each nail shooting area is provided with a first nail gun 43 and a nail ejector. The mouth 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com