Filter device for ventilation device of fuel tank of vehicle

A filter device and ventilation device technology, applied in the field of buffer walls, can solve the problems of adverse effects of combustion process, inability to fully recover, and inability to regenerate buffer walls, and achieve the effects of simple cost, simplified production, and uniform flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

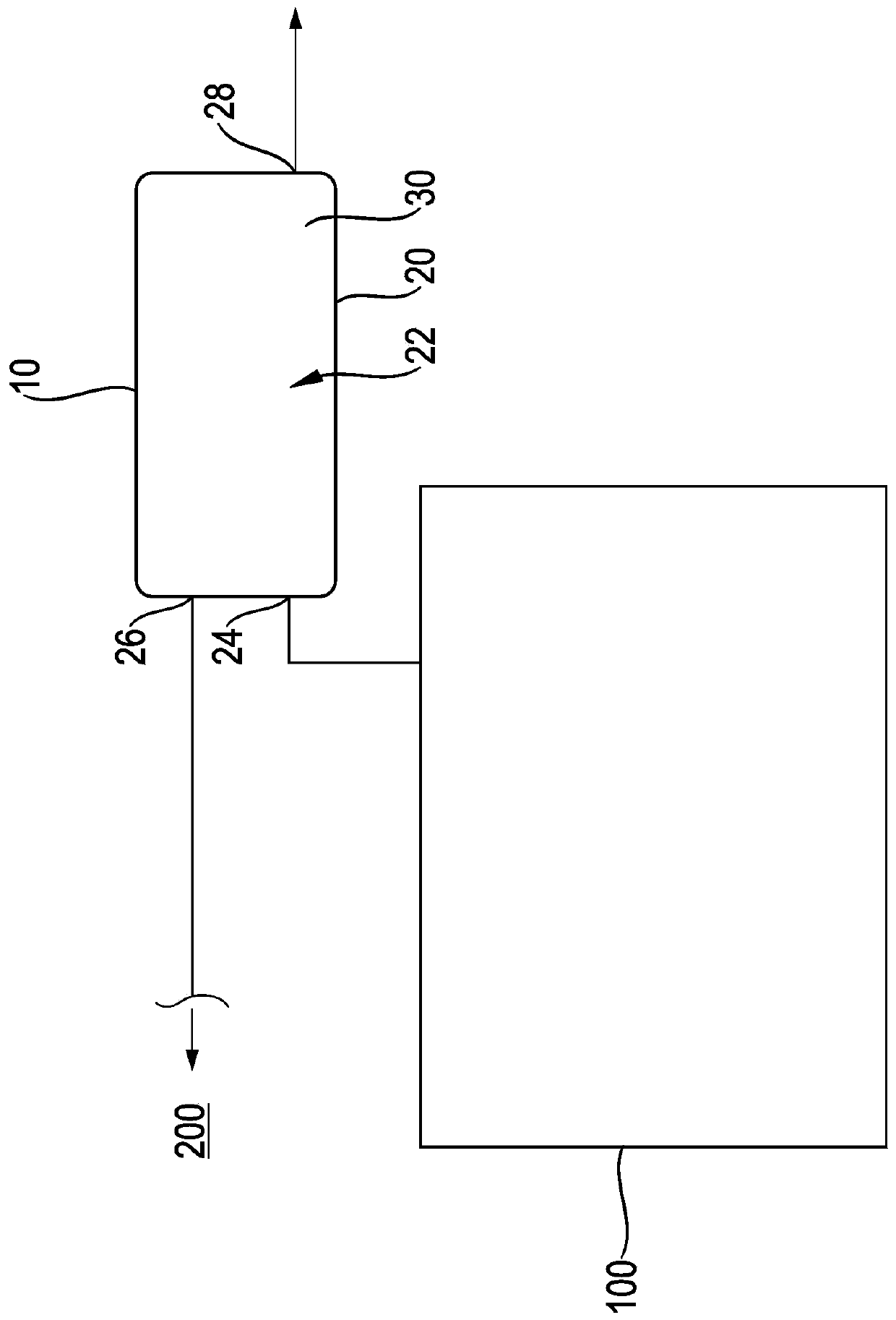

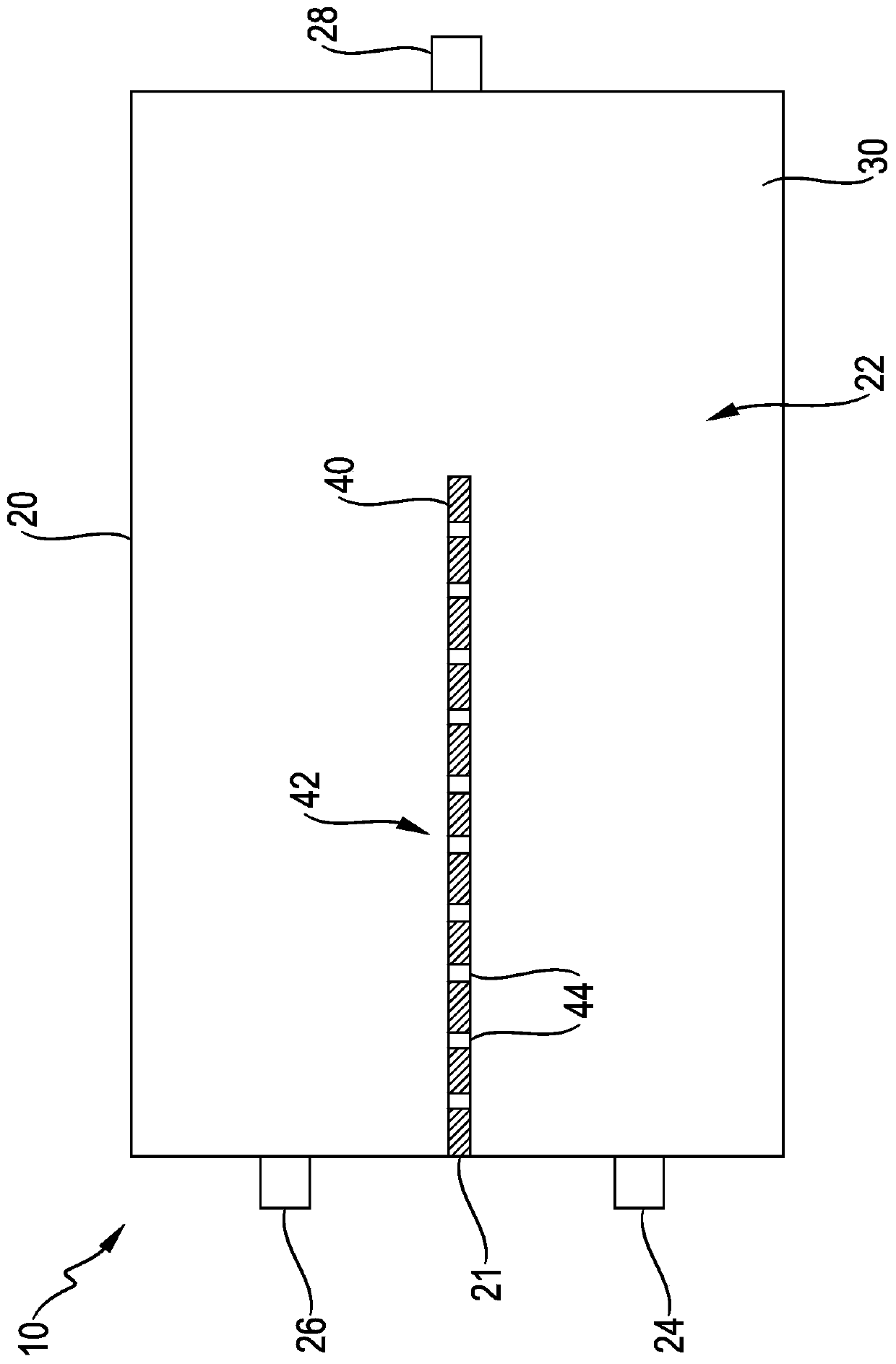

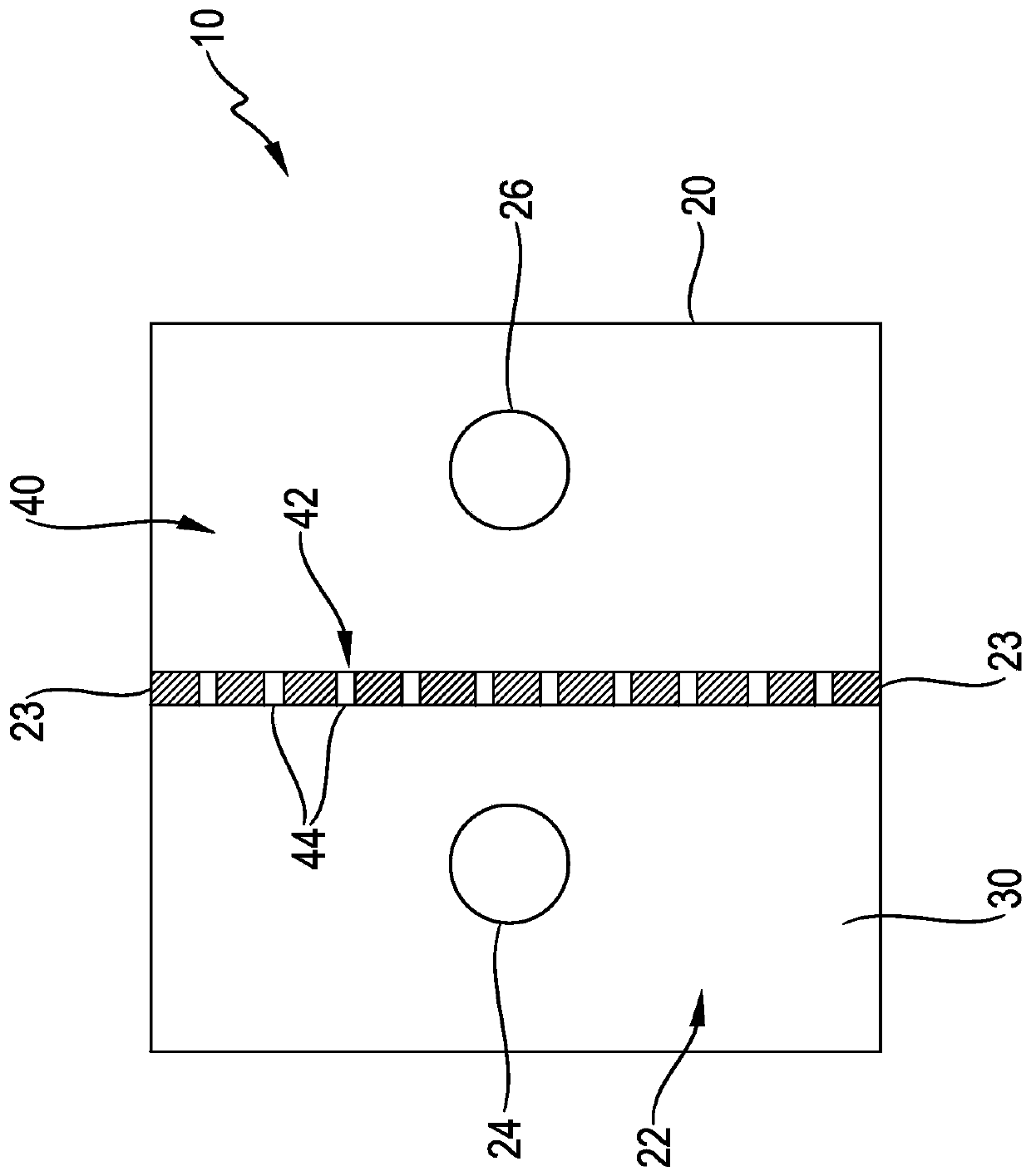

[0028] exist figure 1 In the diagram, the arrangement of the ventilation device for the fuel tank 100 can be seen schematically. Fuel for the internal combustion engine 200 is located in the fuel tank 100 , wherein the supply of the internal combustion engine 200 is provided via a not-shown connecting fluid line between the contents of the fuel tank and the internal combustion engine 200 . If the volume in the fuel tank 100 expands or if a pressure change in the fuel tank 100 occurs due to filling, the excess pressure can be relieved via the ventilation device, in particular via the filter device 10 . In this case, the excess pressure spreads via the tank connection 24 into the filter chamber 22 of the filter housing 20 . There, the excess pressure flows through the sorbent material 30 and the contained fuel vapor is at least partially retained in the sorbent material 30 by adsorption. The gas purified by adsorption in this way can be discharged into the environment of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com