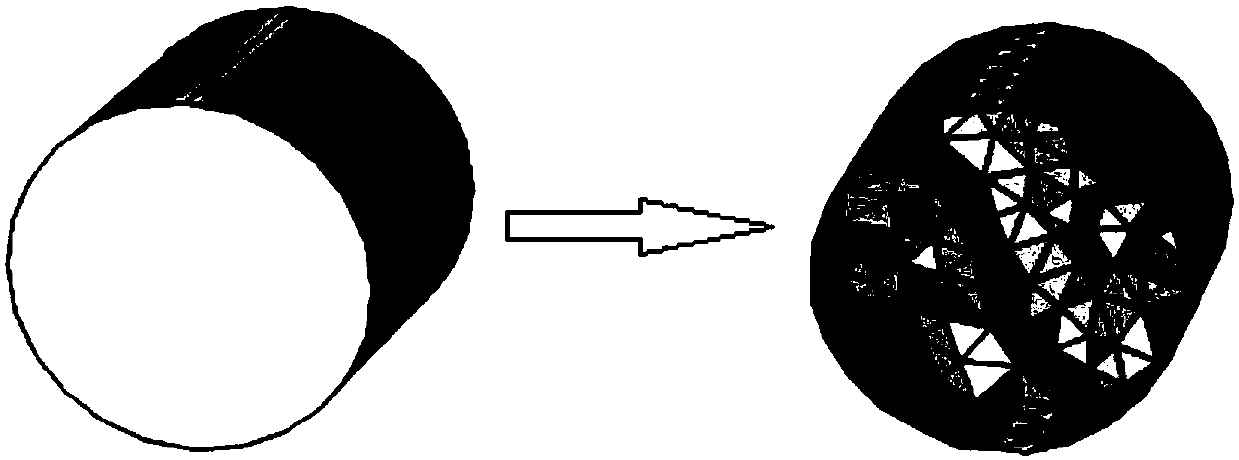

Method for analyzing transient characteristics of metal medium target by body-surface division shooting and bouncing ray method

A bouncing ray method and metal medium technology, which is applied to the analysis of materials, the use of microwave means for material analysis, instruments, etc., can solve the problems of large errors in calculation results and unsuitable for large sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

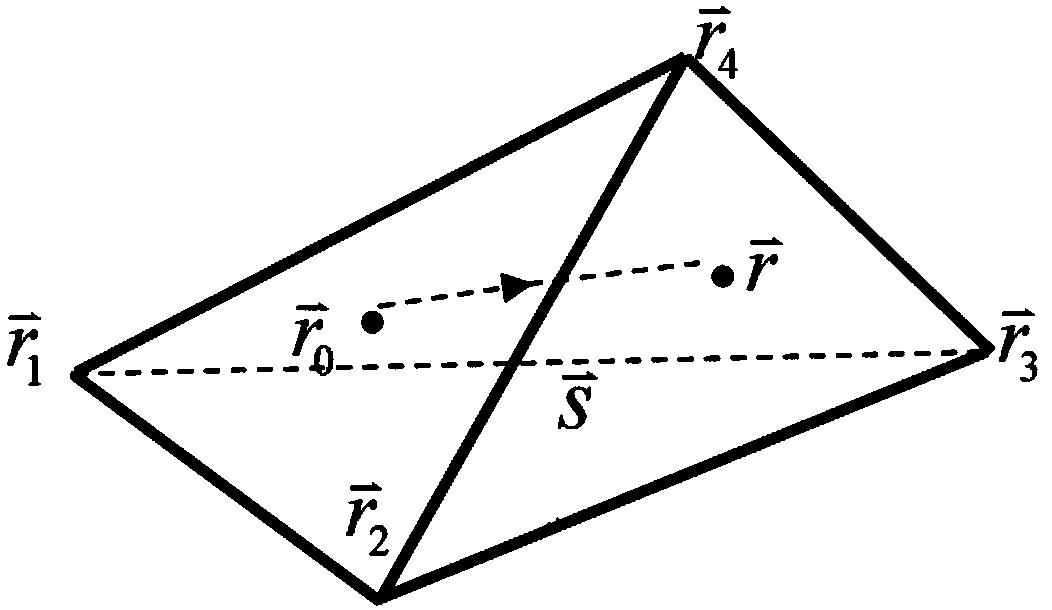

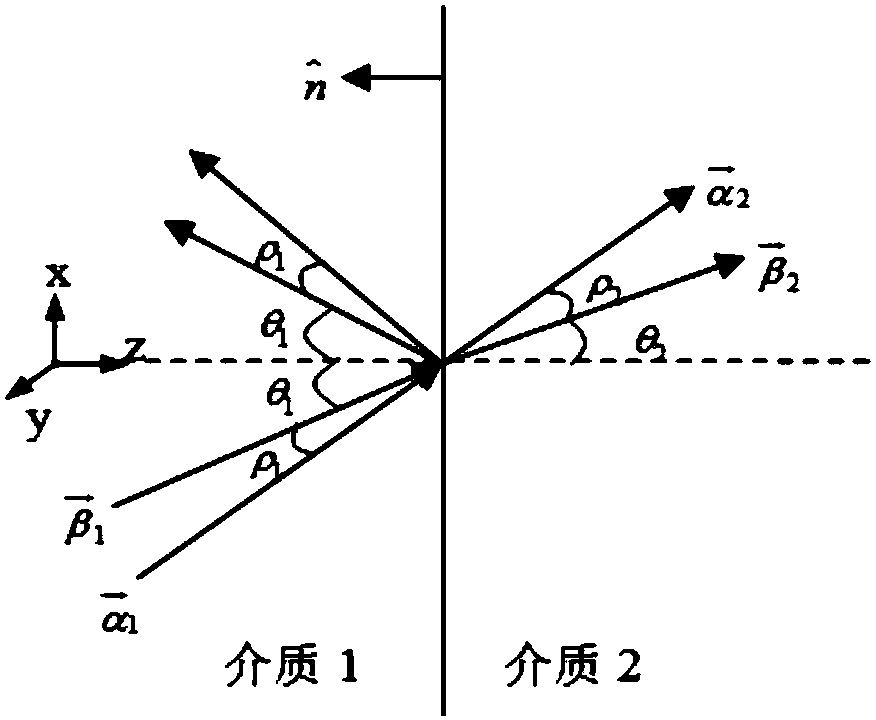

Method used

Image

Examples

Embodiment 1

[0135] Figure 6 A cube model is given, the size of the inner metal cube is 8λ*6λ*5λ, the size of the outer cube is 10λ*8λ*6λ, the middle part is filled with dielectric, the dielectric parameter is 2-j0.2, and the center of the radiation pulse frequency is f 0 =305GHz, the effective frequency band concerned is 300-310GHz, the sampling frequency is 40GHz, the incident direction of the pulse is along θ=45°, Φ=45°, θθ polarization, and the backward observation. Figure 7 is the time-domain response of the metallic medium mixed cube model, Figure 8 Broadband RCS for metallic-dielectric hybrid cube models.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com