Oil well pump inspection period prediction method and device and storage medium

A technology of pump inspection period and prediction method, which is applied in the direction of prediction, instrumentation, data processing applications, etc., and can solve problems such as single qualitative research and one-sidedness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0044] The significance of testing the oil well pump inspection cycle is that the failure frequency of pipes, rods, and pumps in oil wells increases due to wax deposition, sand production, eccentric wear, etc., resulting in a decline in oil well production. The short pump cycle will take up a lot of crude oil production time, and will be forced to invest a lot of manpower, material resources, and financial resources, which not only affects the crude oil production efficiency, but also increases the cost per ton of oil. Therefore, it is necessary to analyze the factors that affect the oil well pump inspection cycle. Factors and prediction of oil well inspection cycle.

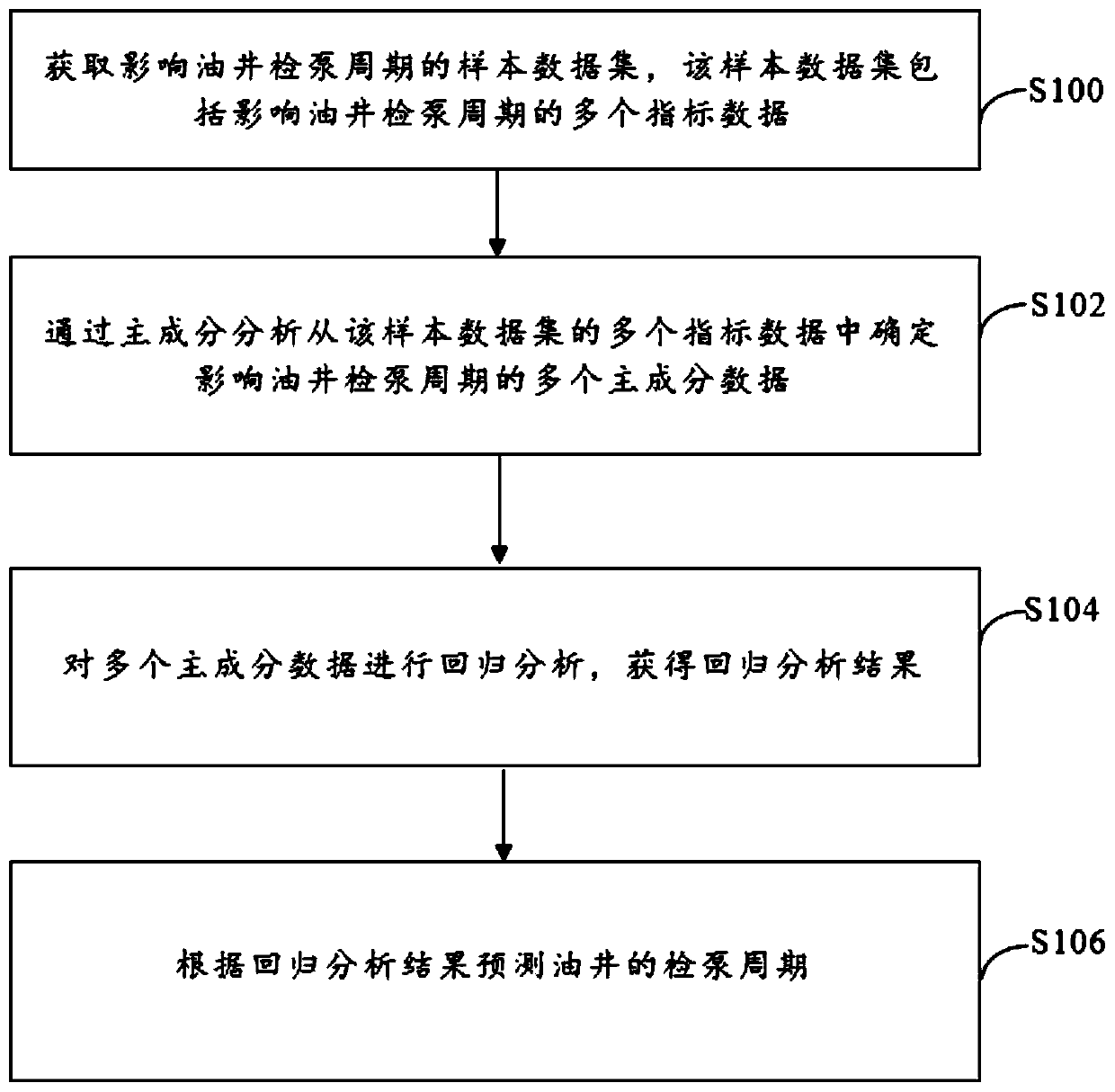

[0045] like figure 1 As shown, the application provides a method for predicting the inspection period of oil well pumps, the method comprising:

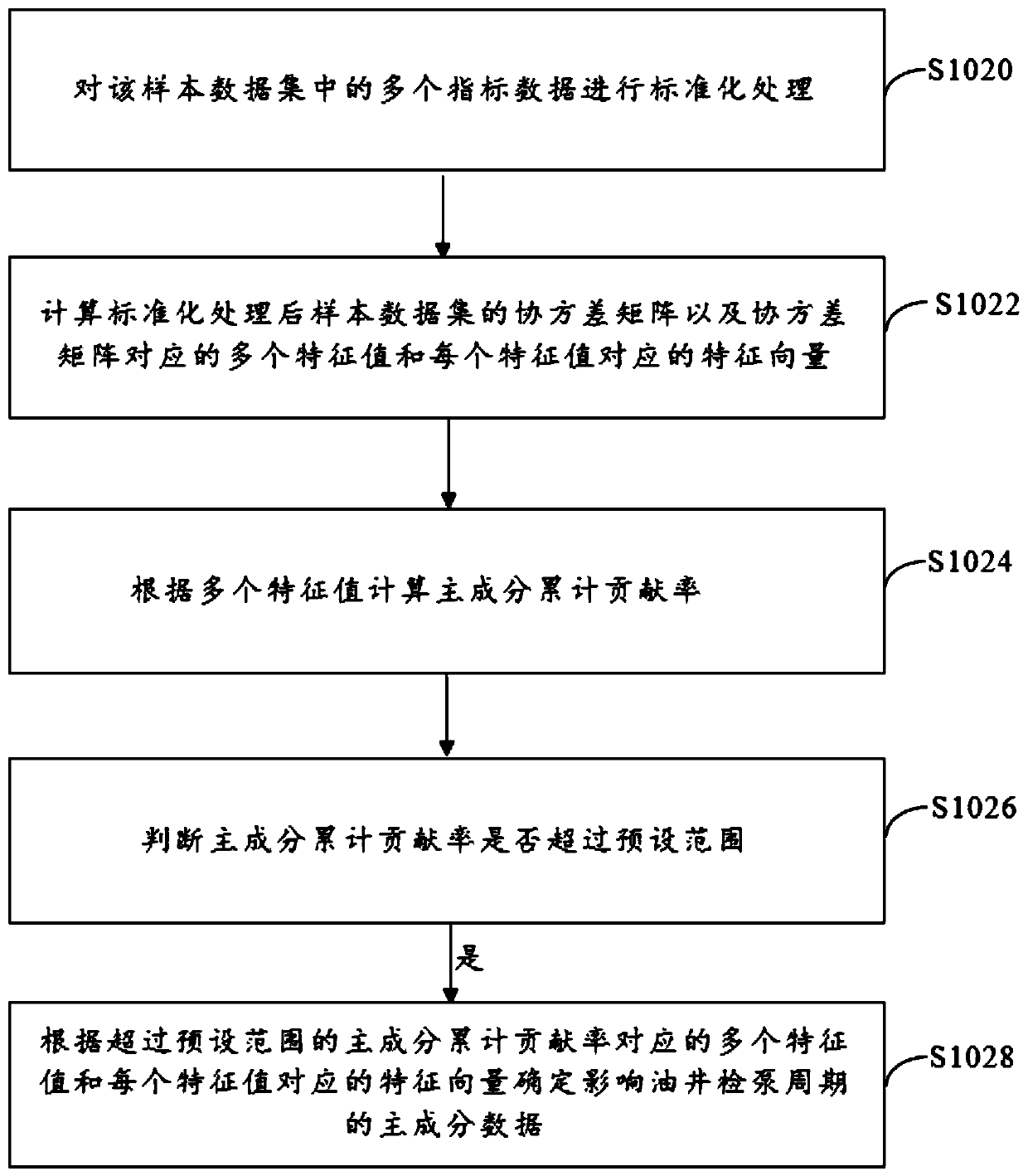

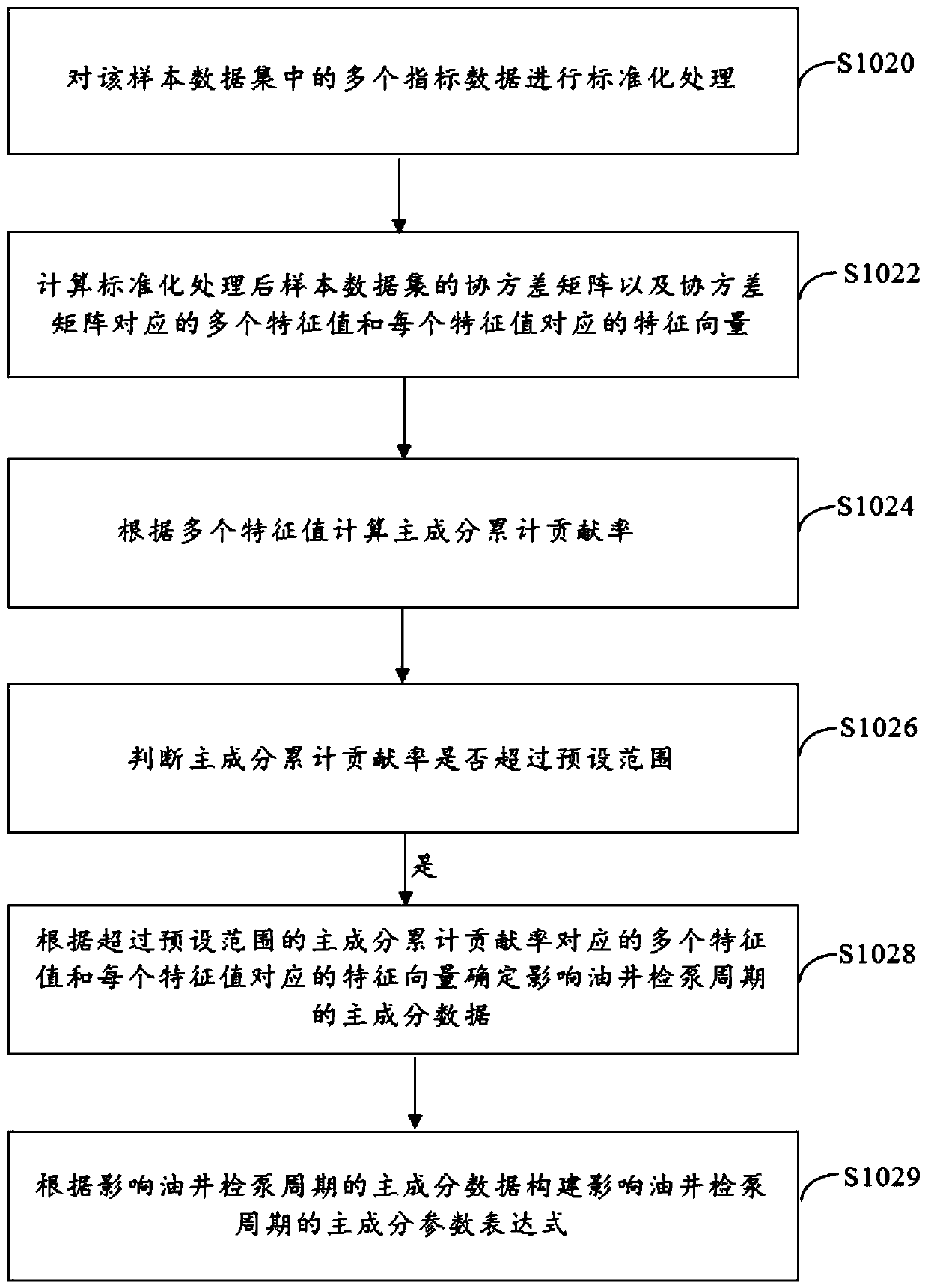

[0046] Step S100: Obtain a sample data set that affects the pump inspection period of the oil well, and the sample data set includes multiple index data that affect t...

no. 2 example

[0085] Figure 6 A schematic structural block diagram of the oil well pump inspection cycle prediction device 2 provided by the application is shown. It should be understood that the device is different from the above-mentioned Figure 1-Figure 5 Corresponding to the method embodiment, each step involved in the method in the first embodiment can be executed. For the specific functions of the device, refer to the above description. To avoid repetition, the detailed description is appropriately omitted here. The device includes at least one software function module that can be stored in a memory in the form of software or firmware (firmware) or solidified in an operating system (operating system, OS) of the device. Specifically, the device includes: an acquisition module 200, used to acquire a sample data set that affects the oil well pump inspection cycle, the sample data set includes multiple index data that affects the oil well pump inspection cycle; From the multiple index ...

no. 3 example

[0093] like Figure 7 As shown, the present application provides an electronic device, including: a processor 301, a memory 302 connected to the processor, the memory 302 stores a storage medium 303 executable by the processor 301, and when the computing device is running, the processor 301 The storage medium 303 is executed to execute the method in the first embodiment or any optional implementation manner of the first embodiment during execution.

[0094]The present application provides a storage medium 303, on which a computer program is stored, and when the computer program is run by a processor, the method in the first embodiment or any optional implementation manner of the first embodiment is executed.

[0095] Wherein, the storage medium 903 can be realized by any type of volatile or non-volatile storage device or their combination, such as static random access memory (Static Random Access Memory, referred to as SRAM), electrically erasable programmable read-only Memor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com