Flavor enhancer for heat-not-burn cigarette smoking section, preparation method and application for flavor enhancer and heat-not-burn cigarette

A heat-not-burn, additive technology, applied in the application, tobacco, smoker's products, etc., can solve the problems of difficulty in satisfying consumers' smoking feeling, lag in flavor development, low matching degree, etc., to improve dryness and fragrance release efficiency. High, comfortable taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

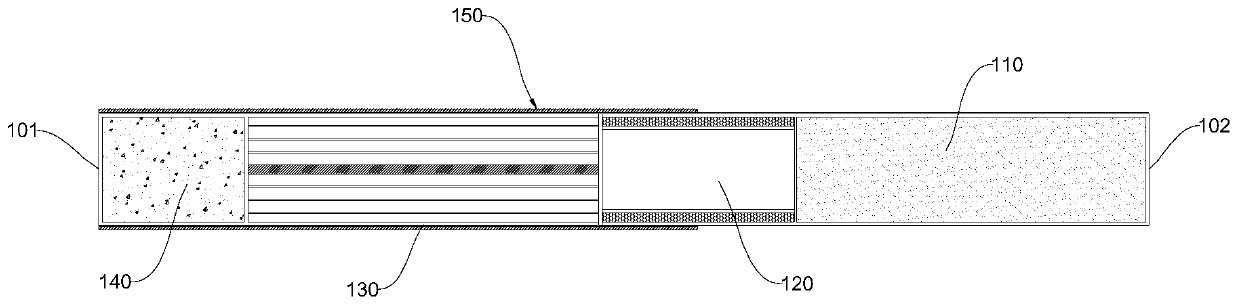

Image

Examples

preparation example Construction

[0042] The embodiment of the present invention also provides a method for preparing a flavor enhancer for the smoking section of a heat-not-burn cigarette, comprising the following steps: mixing the raw materials of the flavor enhancer, and optimizing the types and proportions of the raw materials to make the prepared The flavor enhancer has good flavor coordination, and the flavor enhancer suitable for the smoking section of heat-not-burn cigarettes can be prepared.

[0043] Specifically, the extraction process of the tobacco extract includes the following steps: pulverizing the tobacco raw material to 0.1-5cm 2 , and then extract at a temperature of 100-300°C for 0.5-5h; preferably pulverize to 0.25-4.0cm 2 . By adjusting the extraction temperature, the extracted fragrant raw materials are more suitable for the smoking section, and the improvement effect of the additive on the smoking section is further improved.

[0044] Preferably, before extraction after pulverization, ...

Embodiment 1

[0054] The present embodiment provides a method for preparing a tobacco product, comprising the following steps:

[0055] (1) the preparation of the aroma enhancer for heat-not-burn cigarette smoking section, it comprises the following steps:

[0056] (a) Preparation of tobacco extract: Weigh 120 g of cigars, 70 g of burley tobacco, and 10 g of jujube, respectively, add 100 g of 70% ethanol aqueous solution, and sonicate for 2 hours at 50 °C; then add 560 g of propylene glycol, add water 40g, reflux extraction at 170°C for 3h; after the extraction is completed, the filtrate is collected by filtration, and it is kept for 24h after resting.

[0057] (b) Preparation of plant extracts: 20 g of dried ginger, 20 g of Luo Han Guo, and 50 g of barley were weighed in 700 g of propylene glycol solution for reflux extraction for 5 h, and the filtrate was collected by filtration for subsequent use.

[0058] (c) Preparation and addition of flavor enhancer: take 40 parts of tobacco extract...

Embodiment 2

[0062] The present embodiment provides a method for preparing a tobacco product, comprising the following steps:

[0063] (1) the preparation of the aroma enhancer for heat-not-burn cigarette smoking section, it comprises the following steps:

[0064] (a) Preparation of tobacco extract: Weigh 120 g of cigars, 70 g of burley tobacco, and 10 g of jujube, respectively, add 100 g of 70% ethanol aqueous solution, and sonicate for 2 hours at 50 °C; then add 560 g of propylene glycol, add water 40g, reflux extraction at 170°C for 3h; after the extraction is completed, the filtrate is collected by filtration, and it is kept for 24h after resting.

[0065] (b) Preparation of plant extracts: 20 g of dried ginger, 20 g of Luo Han Guo, and 50 g of barley were weighed in 700 g of propylene glycol solution for reflux extraction for 5 h, and the filtrate was collected by filtration for subsequent use.

[0066] (c) Preparation and addition of flavor enhancer: take 40 parts of tobacco extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com