File for trimming cracks of ceramic edge

An edge and ceramic technology, which is applied in the direction of filing/filing tools, filing/filing devices, metal processing equipment, etc., can solve problems such as bumps, skin cuts, waste of energy and money, etc., and achieve operational Easy to use, prevents cuts, and beautiful lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

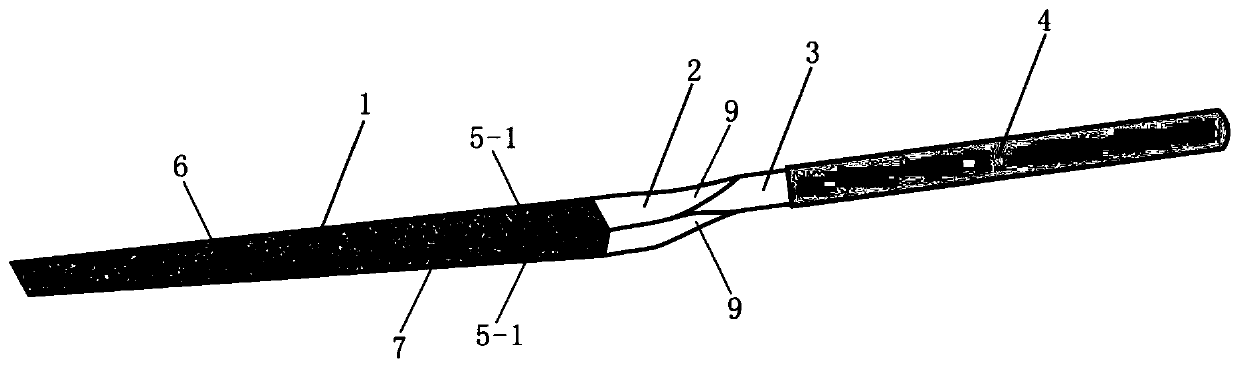

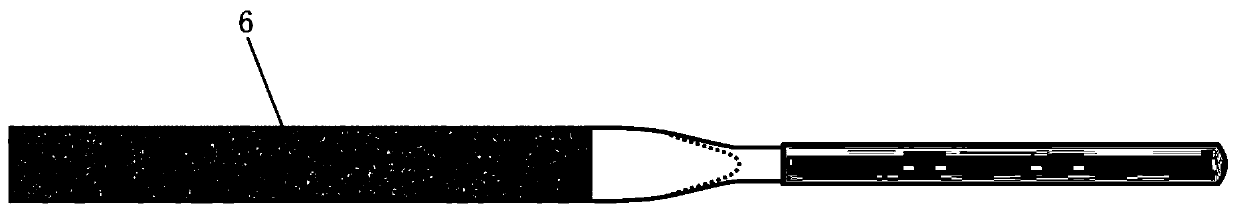

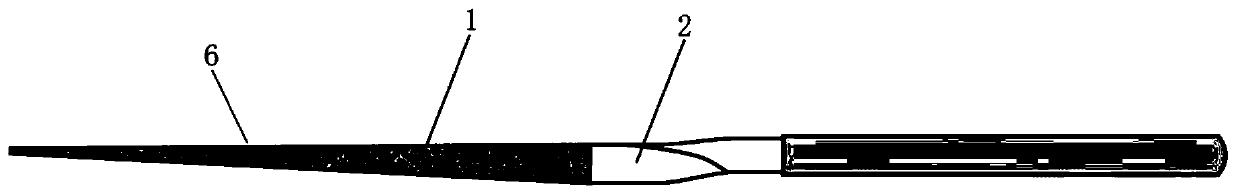

[0044] Embodiment 1: as figure 1 As shown in the figure, the components of a file for repairing cracks on ceramic edges include a file body 1 , a transition section 2 , a handle 3 , and an anti-slip sleeve 4 for the handle. The file body 1 is composed of a metal substrate and a working layer 5-1, and the working layer 5-1 is fastened on the surface of the metal substrate. The working layer 5-1 is composed of substances with high hardness such as corundum or diamond, combined with various bonding agents through electroplating or brazing production processes, and the substances with high hardness such as corundum or diamond are fastened to the metal substrate. The mixed layer on the surface, which is the main body used for filing work. The file body 1 and the handle 3 are connected by a transition section 2 . The metal substrate of the file body 1, the transition section 2 and the handle 3 are integrally formed. The handle anti-slip cover 4 is wrapped around the handle 3 outs...

Embodiment 2

[0053] Embodiment 2: as Figure 5 As shown in the figure, the components of a file for repairing cracks on ceramic edges include a file body 1 , a transition section 2 , a handle 3 , and an anti-slip sleeve 4 for the handle. File teeth 5-2 with filing function are distributed on the surface of the file body 1, which is the main body for filing work. The file body 1 and the handle 3 are connected by a transition section 2 . The file body 1, the transition section 2 and the handle 3 are integrally formed. The handle anti-slip cover 4 is wrapped around the handle 3 outside.

[0054] The only difference between embodiment 2 and embodiment 1 is the structure of the file body. The surface of the file body 1 in Example 1 is fastened with a working layer 5-1 for filing function, and the surface of the file body 1 in Example 2 is distributed with file teeth 5-2 for filing function. Other implementation manners of Embodiment 2 are identical to Embodiment 1, and will not be repeated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com