A furniture board grinding device

A technology for plates and furniture, which is applied in the direction of grinding drive devices, grinders, abrasive belt grinders, etc. It can solve the problems of difficult control of grinding precision, difficulty in ensuring flatness of plates, and low grinding efficiency, so as to prevent friction and energy loss and improve grinding efficiency. Efficiency and effect, effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

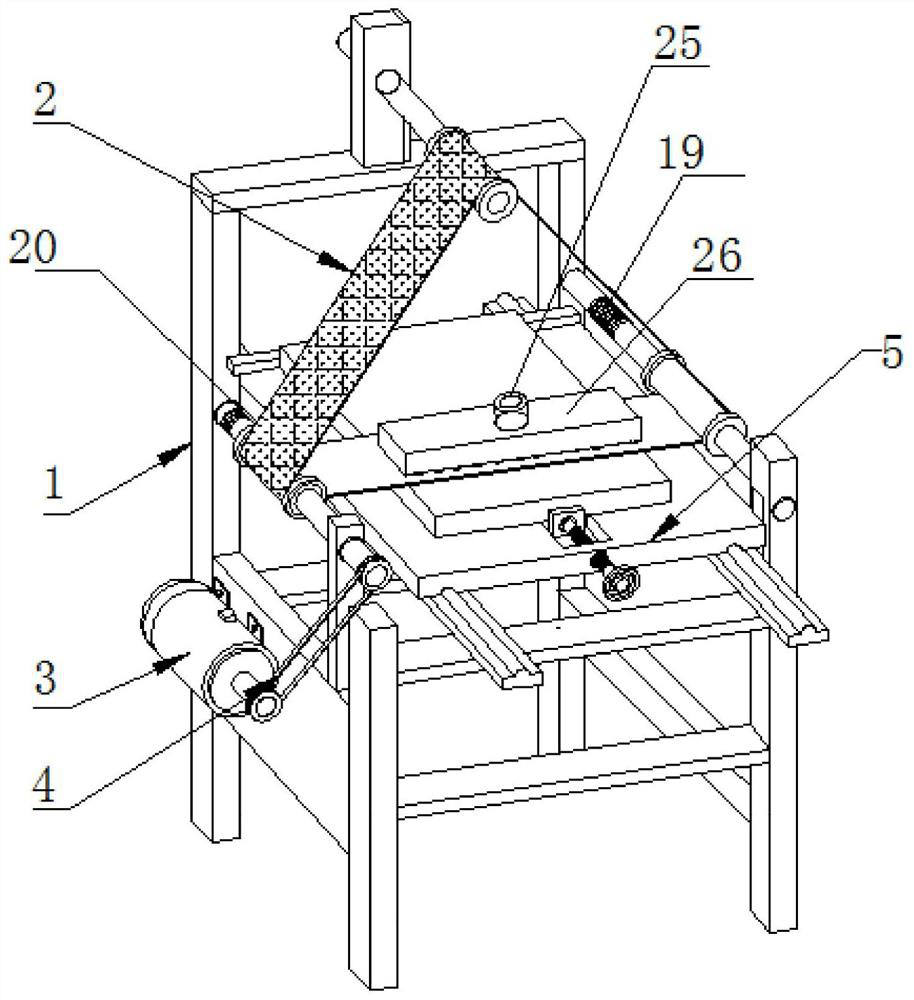

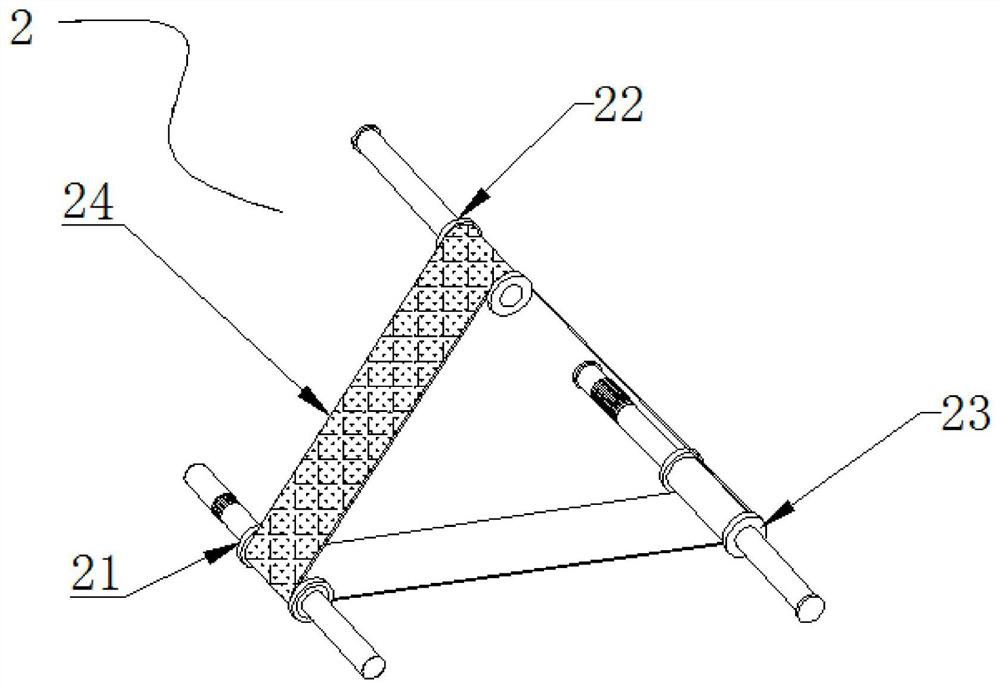

[0026] see Figure 1-6 , in an embodiment of the present invention, a furniture board grinding device includes a main frame 1, a grinding mechanism 2 and a grinding pressure control mechanism 26, wherein the main frame 1 is provided with a workbench 5 that can slide back and forth, and the work The grinding mechanism 2 is arranged above the table, and the grinding mechanism is a belt type grinding mechanism, and the grinding pressure control mechanism is arranged above the part of the grinding mechanism that is in contact with the plate to be polished on the workbench 26, characterized in that,

[0027] The grinding pressure control mechanism includes a pressure belt 266. When the pressure belt 266 exerts pressure on the grinding mechanism towards the direction of the belt grinding plate, the pressure belt also moves with the grinding mechanism; the grinding pressure control mechanism adopts Connecting seat 25 is installed on the main frame;

[0028] It also includes an angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com