A stabilizing and rotating wiping device for capacitor can sealing equipment

A capacitor and leveling technology, which is applied in the field of leveling and wiping devices, can solve the problems of reducing the service life of capacitors, affecting the appearance, and burrs, so as to achieve the effect of stable core package structure and ensuring appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

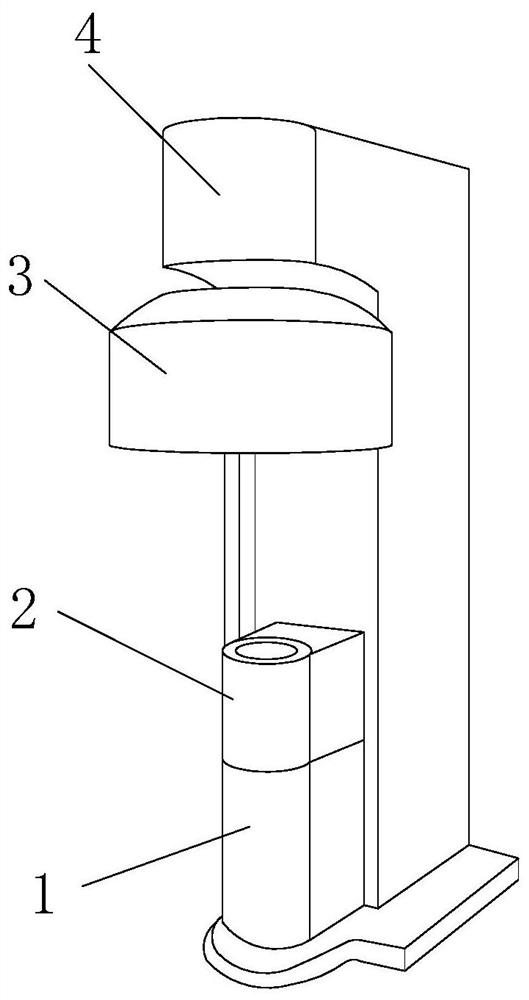

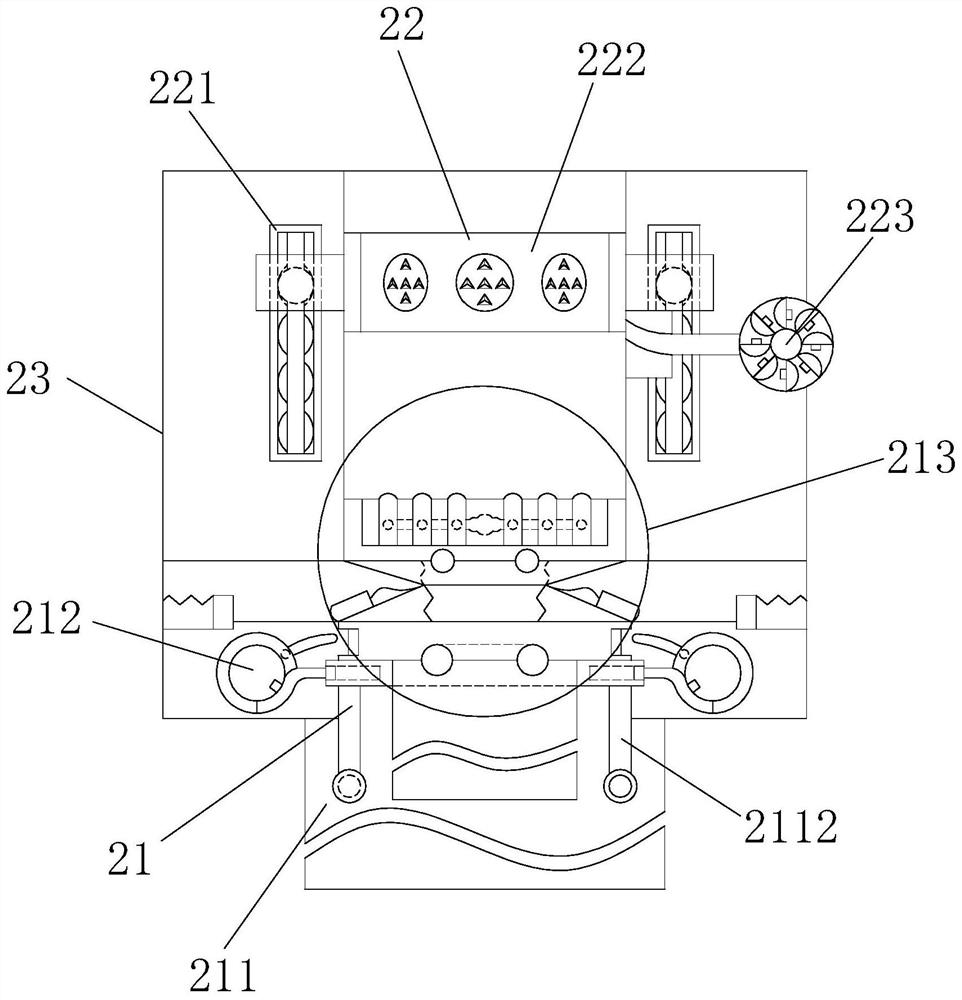

[0026] Such as Figure 1-Figure 7 As shown, the present invention provides a stabilizing rotary wiping device for capacitor can sealing equipment. The device 2 is mechanically coordinated, the packaging head 3 is installed directly above the stable and leveling rotary wiping device 2, the body 4 is pneumatically matched with the stamping seat 1, and the stable and leveling rotary wiping device 2 includes a de-vibration mechanism 21, a rotary brush mechanism 22. The housing 23, the de-vibration mechanism 21 is installed horizontally at the lower end inside the housing 23, and the rotating brush mechanism 22 is installed directly above the de-vibration mechanism 21.

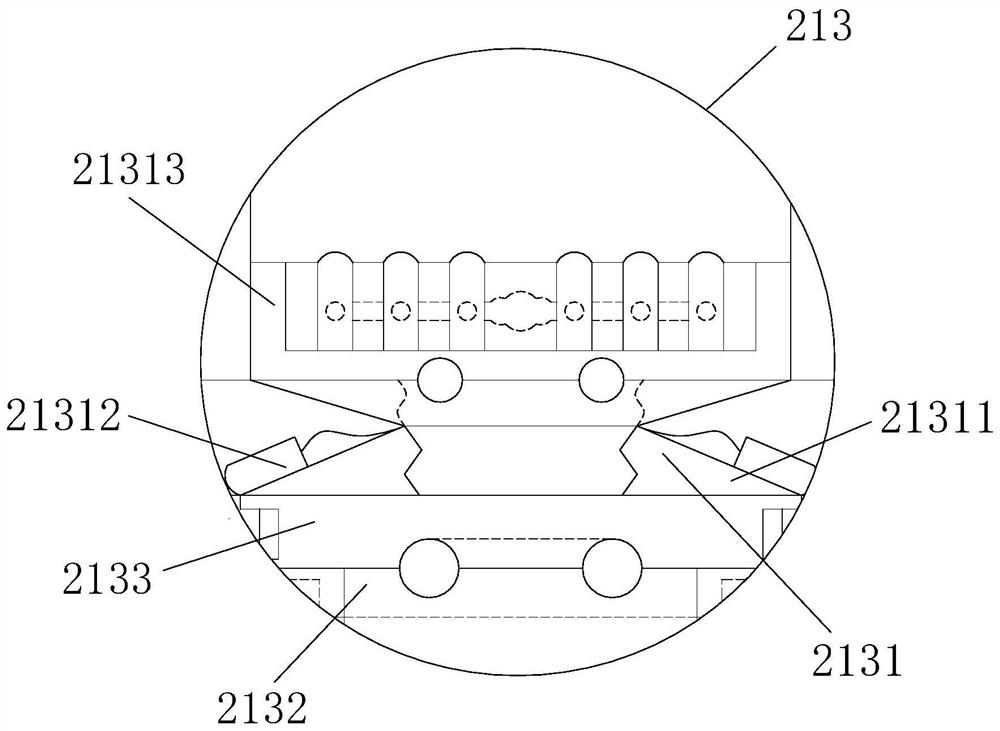

[0027] The devibration mechanism 21 includes a force-gathering mechanism 211, a guide plate 212, and a straightening mechanism 213. The force-gathering mechanism 211 cooperates mechanically with the turntable of the straightening mechanism 213, and the guide plate 212 and the straightening mechanism 213 pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com