One-way valve assembling and detecting machine

A one-way valve and testing machine technology, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of low labor efficiency and high cost, reduce labor costs, improve work efficiency, and improve the quality of processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

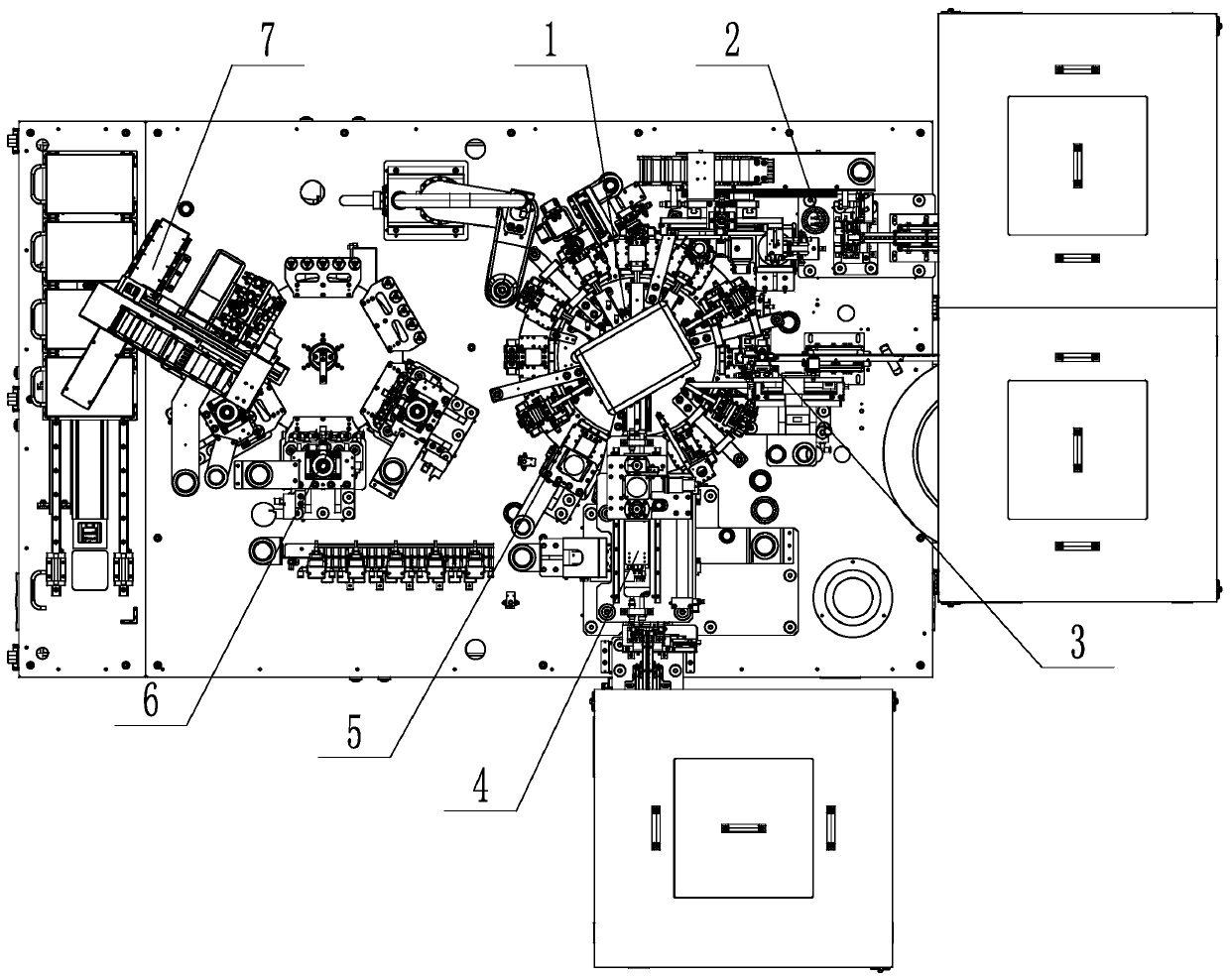

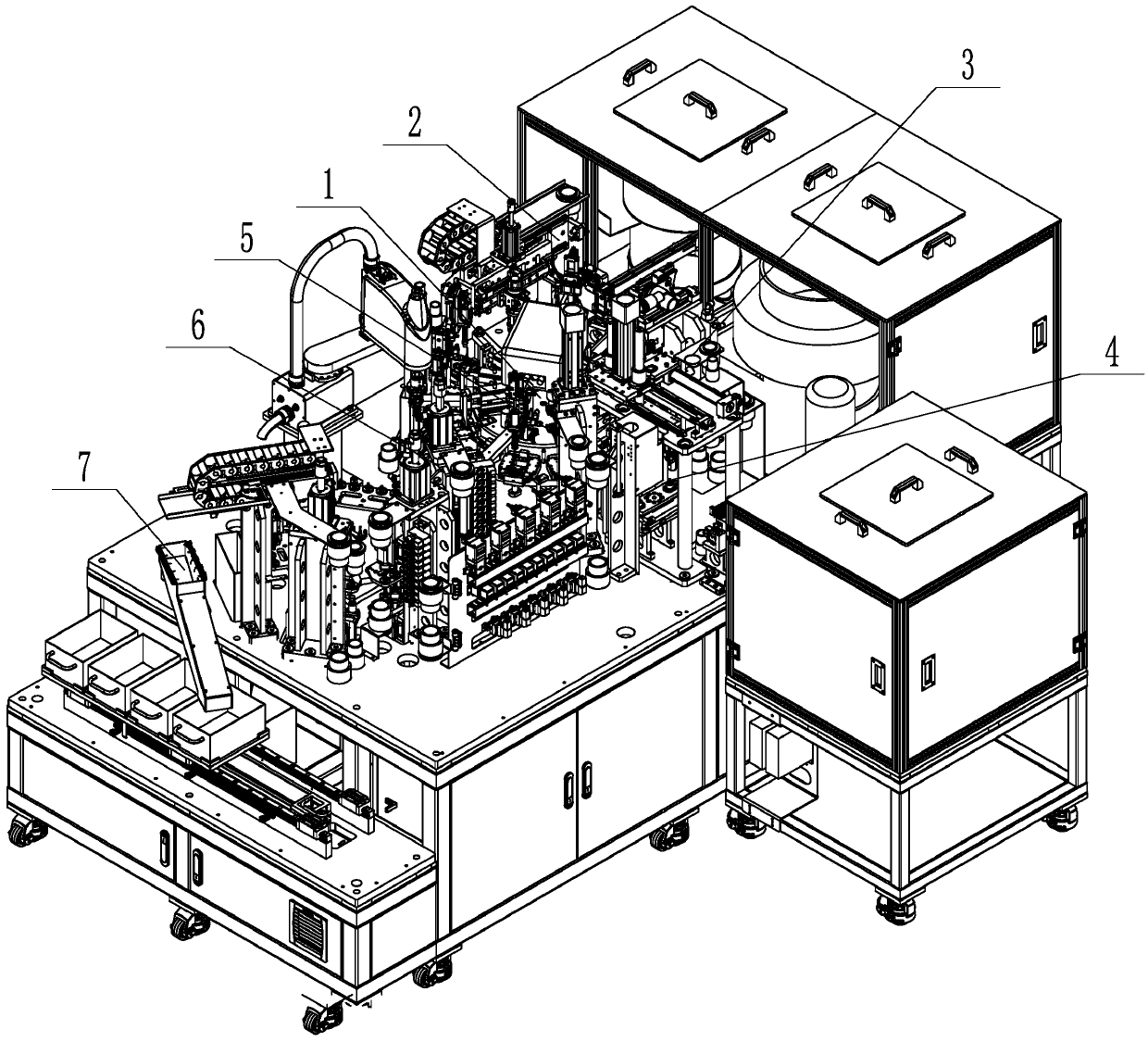

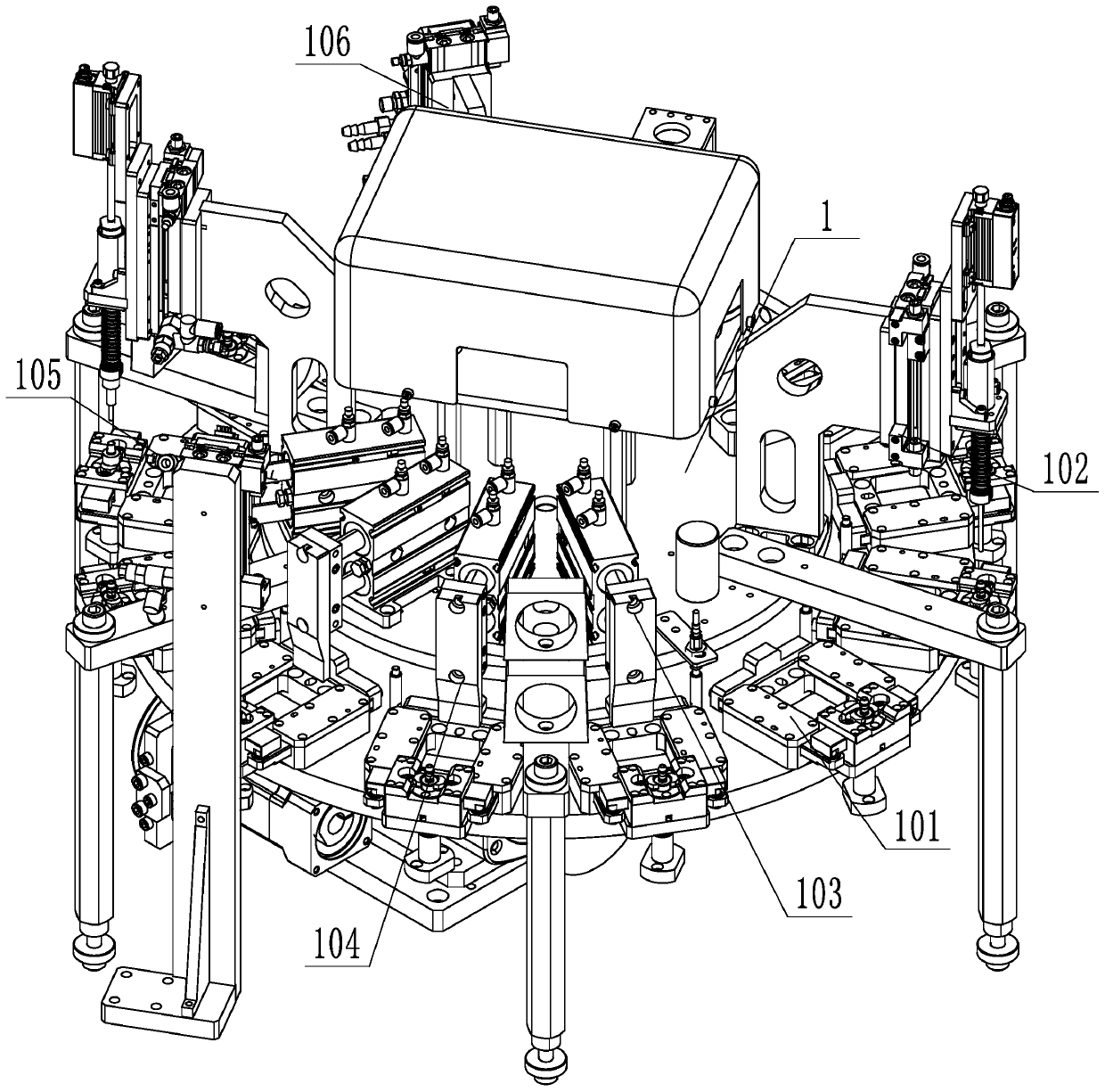

[0033] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-16 As shown, the one-way valve assembly inspection machine includes the one-way valve to be assembled, the assembly turntable 1, the water outlet assembly inspection mechanism 2, the rubber sleeve assembly processing mechanism 3, the water inlet assembly inspection mechanism 4, and the secondary pressing mechanism 5 , pressure opening and leakage detection mechanism 6, finished product collection mechanism 7, wherein the one-way valve is composed of a water outlet, a rubber sleeve and a water inlet; the assembly inspection machine for assembling these three parts includes: assembly turntable 1: can be The shaft rotates and cooperates with other mechanisms to complete the assembly and detection process of the water outlet, rubber sleeve and water inlet; the water outlet assembly detection mechanism 2: set on one side of the assembly turntable 1 and send the water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com