Linkage control type handheld washing machine

A cleaning machine, control technology, applied in pump control, machine/engine, liquid variable volume machinery, etc., can solve problems such as affecting the stability of the other hand, affecting the operating experience, etc., to improve the use experience, The effect of reducing the difficulty of operation and improving the comfort of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

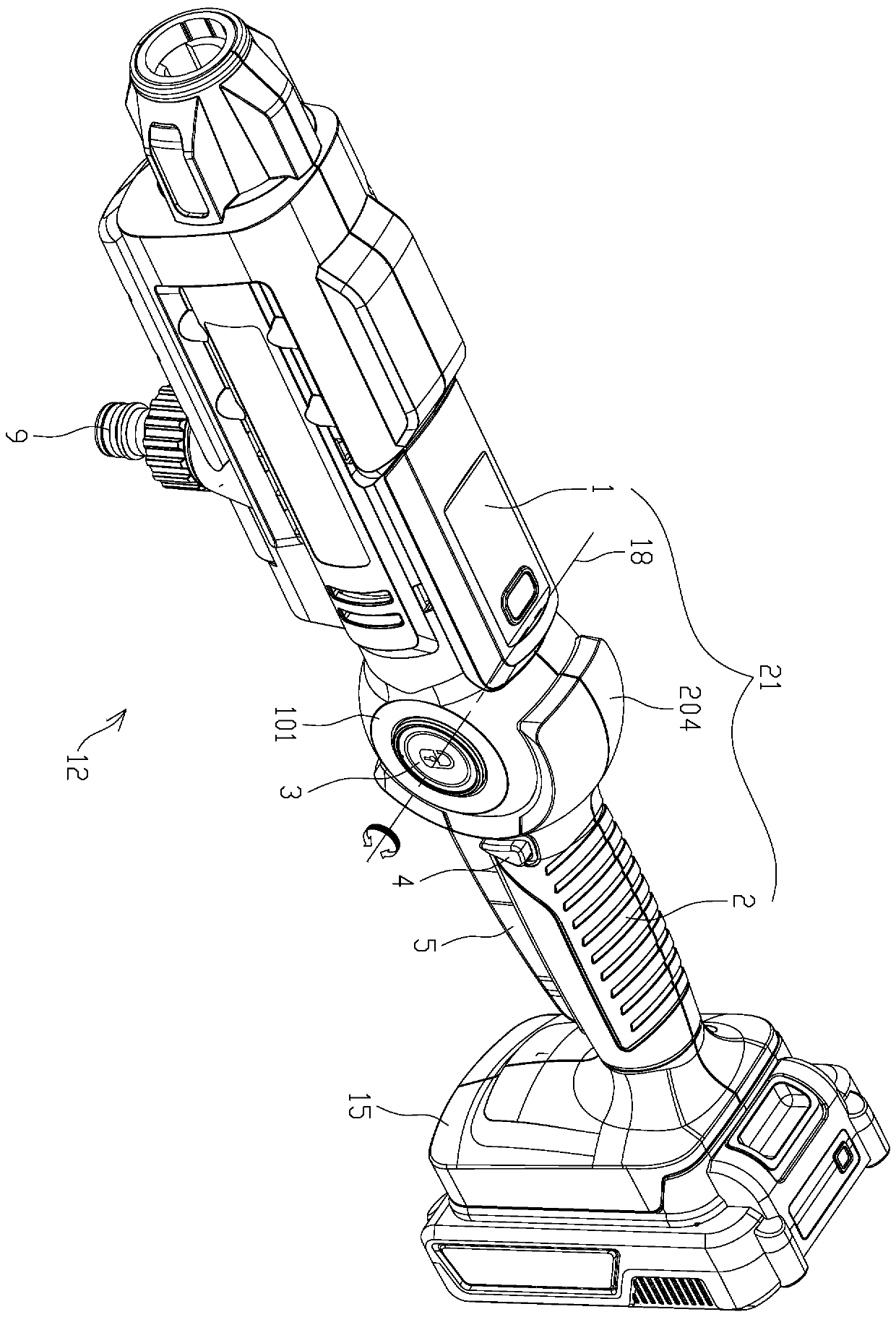

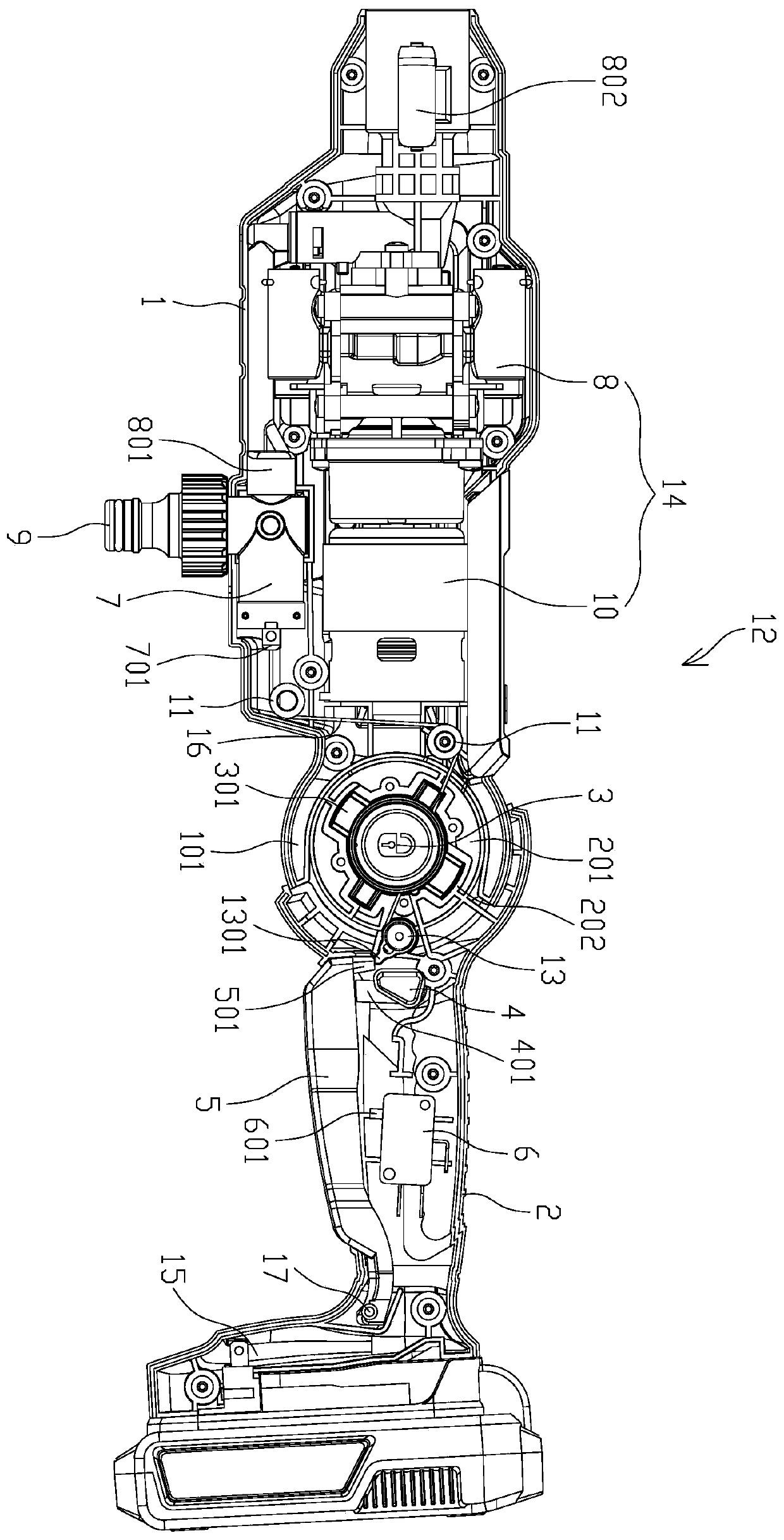

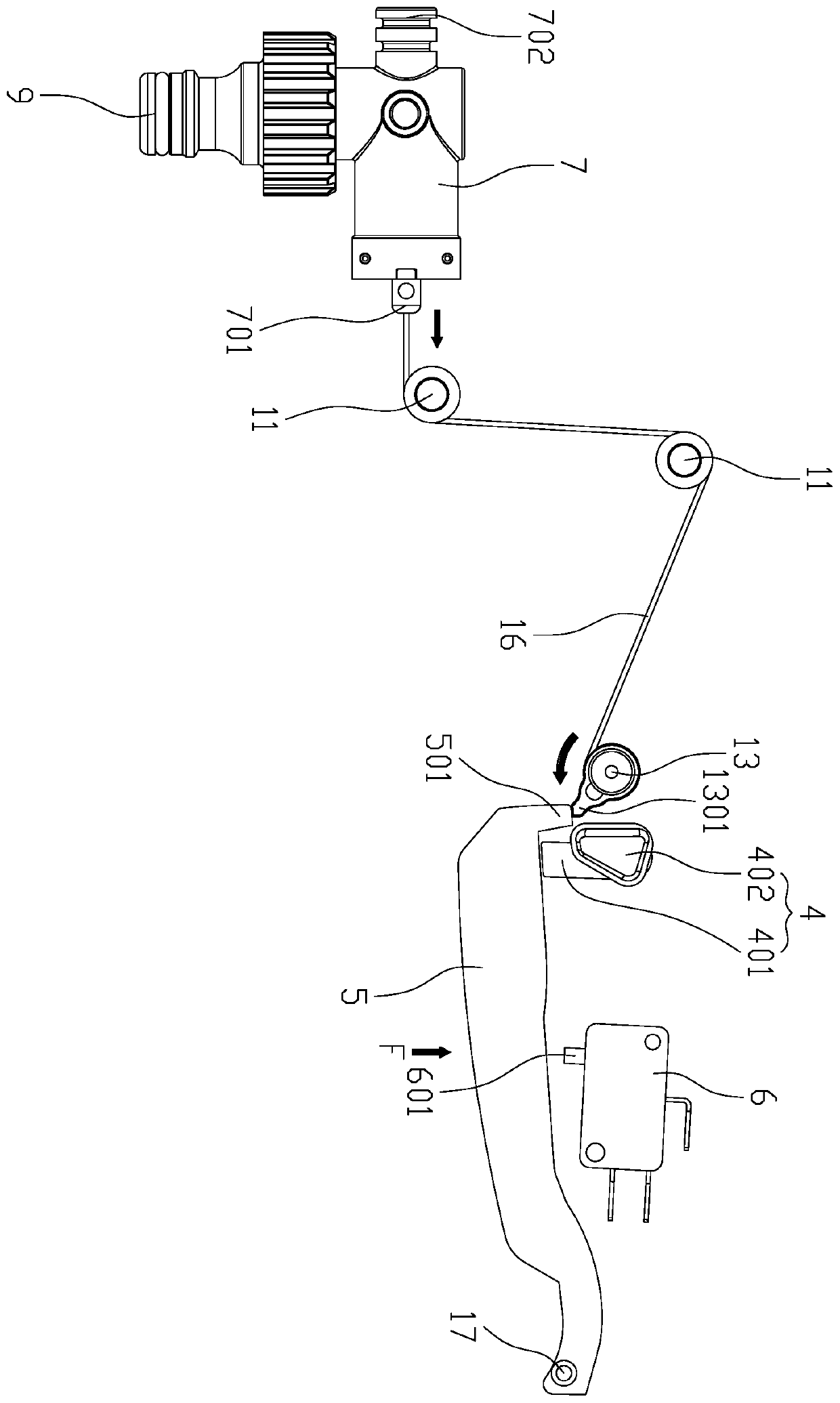

[0050] Such as figure 1 , 2 , 3, 6, 7, 8, 9, and 10, a linkage control type hand-held washing machine 12 includes: a housing 21, an adjustment switch 3, a reset member I20, a battery pack 15, a motor pump unit 14, a water inlet Valve 7, control trigger 5, switch 6, flexible traction member 16, guide member I11, rotating member 13, safety switch 4 and reset member II.

[0051] The casing 21 includes a main casing 1 and a handle 2. The main casing 1 is used to accommodate the motor pump unit 14, the water inlet valve 7 and related components. The handle 2 is used as a handle for people to hold and is used to accommodate the switch 6 and related components. Both the main casing 1 and the handle 2 are of half-shell structure, and are connected by screws so as to form a cavity inside them for accommodating components.

[0052] The main casing 1 has a rear connecting portion 101 , and the handle 2 has a front connecting portion 201 forming a rotational connection with the rear conne...

Embodiment 2

[0067] Such as Figure 11 As shown, the difference between the present embodiment and the first embodiment is that the two ends of the receiving portion I103 of the main casing 1 respectively pass through the rear connecting portion 101 along the direction of the axis 18 to form two operation holes respectively accommodating the ends of the adjustment switch 3 105. At this time, both ends of the regulating switch 3 can be pressed by the user so that the regulating switch 3 can slide between its first position and its second position, and the switch between the two positions does not need to be completed by the reset member I20. In this embodiment, the adjusting switch 3 can also be used as a pivot for the rotational connection between the main casing 1 and the handle 2 .

Embodiment 3

[0069] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that the rotating member 13 is a roller with a gear tooth portion I1302, and correspondingly, the control trigger 5 has a gear tooth portion II502 meshing with the gear tooth portion I1302. When the control trigger 5 rotates around the pivot 17 , the turret 13 rotates with the control trigger 5 under the meshing effect of the gear tooth part II502 and the gear tooth part I1302 so as to realize the traction of the flexible traction member 16 to the spool 701 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com