Elastic member made of compressible material and assembly method thereof

A technology of elastic components and assembly surfaces, applied to springs made of plastic materials, heating methods, low internal friction springs, etc., can solve the problems of not being able to press the condenser at the same time, achieve simple structure, good reliability, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

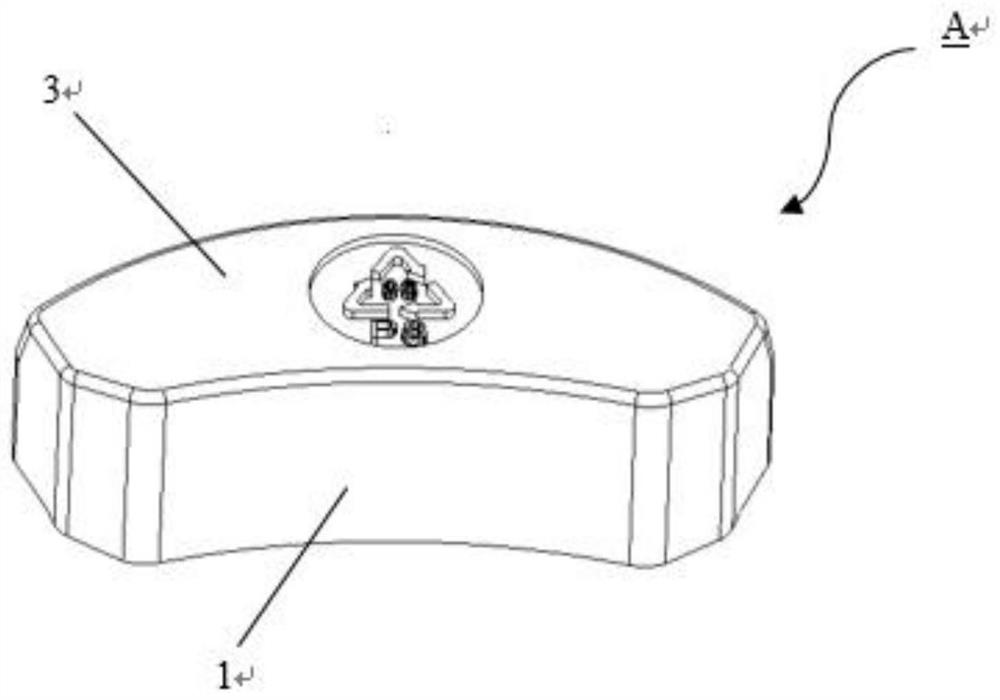

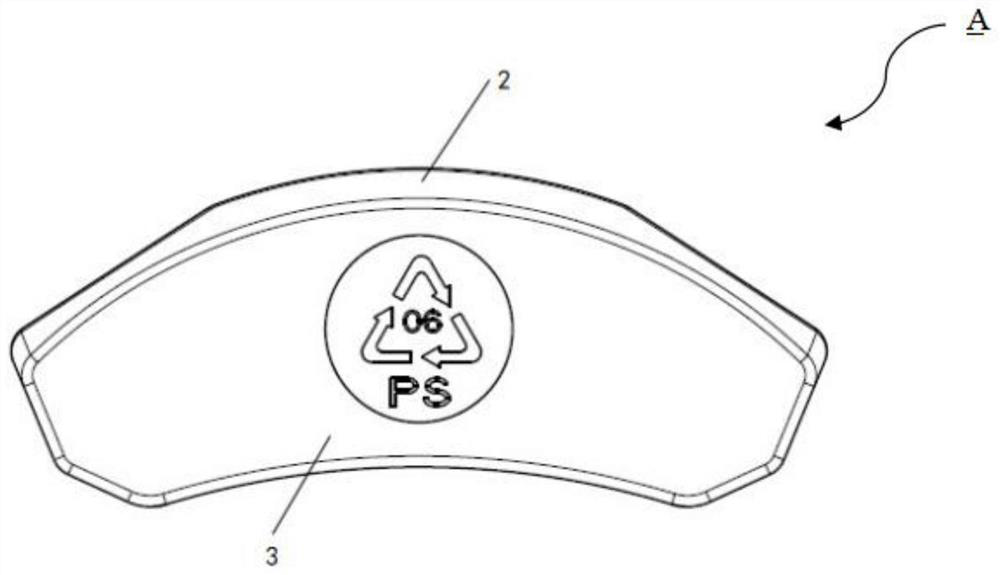

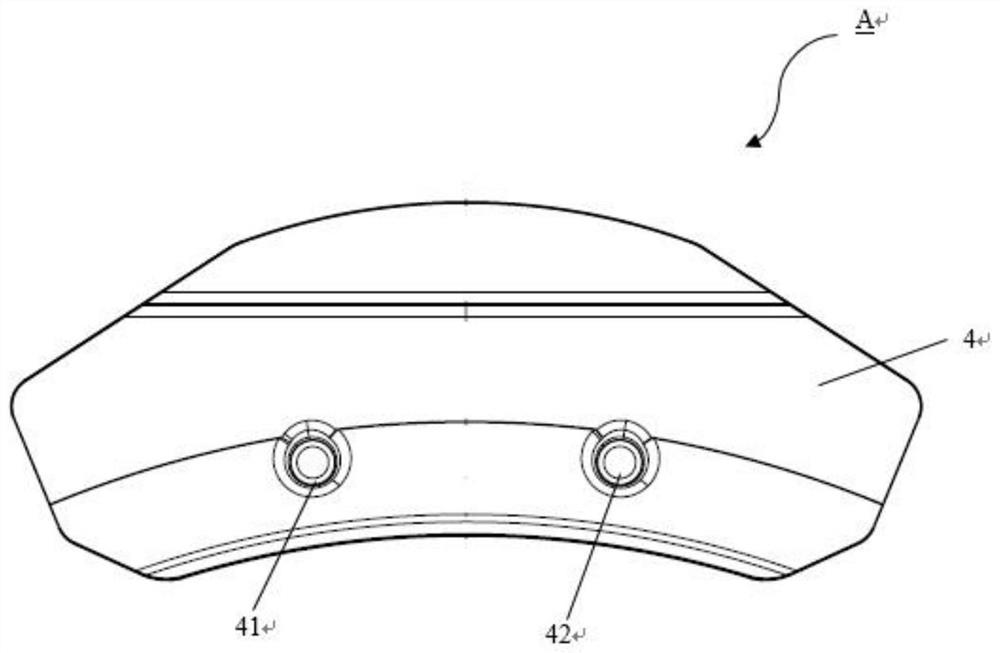

[0049] Such as Figure 1-8 As shown, the elastic member A made of compressible material in this embodiment is a foam member, which needs to be compatible. The housing 6 has a housing cover 61, a housing body 62, and the inner wall surface 63 of the housing cover 61 includes the inner top surface 631 of the housing. , the inner ring surface 632 of the casing, and the outer ring surface 633 of the casing, these surfaces form a mating surface for assembly and cooperation with the foam member.

[0050] Due to changes in specifications and dimensions, an assembly gap is formed between the upper surface of the equipment to be assembled and the inner top surface, inner ring surface, and outer ring surface of the housing.

[0051] The elastic member A used to fill the above-mentioned assembling gap and at the same time tightly install the casing and the device together includes a first assembling surface 1 and a second assembling surface 2 . The first assembly surface 1 and the secon...

Embodiment 2

[0061] Based on the same or similar inventive concepts, the present invention also provides an embodiment of applying the elastic member to the external unit of the air conditioner with the upper air outlet. inside the shell. This embodiment proposes to use the elastic member of the present invention to solve the compatibility problem, avoiding the friction and loosening caused by the vibration of the external air conditioner equipped with the new specification due to the change of the specification of the condenser.

[0062] The air conditioner external unit of the upper air outlet type will be described in detail below in conjunction with the accompanying drawings.

[0063] Such as Figure 6-Figure 8 As shown, the air conditioner outdoor unit in this embodiment includes a casing 6, a condenser 5 and an elastic member A made of compressible material. The outdoor unit of the air conditioner has an upward air outlet, and the casing includes a casing cover 61 and a casing body...

Embodiment 3

[0075] The elastic member made of compressible material is not only suitable for solving the support and fixing between a single product device and the shell structure, but also especially suitable for solving the problem that a single shell is compatible with multiple models (or multiple condensers, multiple cooling sections) question. In addition to air conditioners, it can also be used in dehumidifiers, air purifiers and other occasions that need to solve the problem of sharing the shell.

[0076] Figure 9 A case of applying the elastic member made of compressible material of the present invention to an outdoor unit of a side air conditioner is exemplified.

[0077] Such as Figure 9As shown, the air conditioner outdoor unit in this embodiment is a side air outlet, including a casing 6, a condenser 5 and an elastic member A made of compressible material. The housing includes a housing cover 61 and a housing body (not shown in the figure), the housing cover 61 covers the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com