High-temperature air source water-mixing cooling method suitable for underwater high-speed vehicle

A technology for aircraft and high temperature, which is applied in gas/liquid distribution and storage, ship propulsion, ship parts, etc. It can solve the problems of inability to cool down the gas, achieve the effect of increasing the overall performance, improving the cooling effect, and reducing the consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

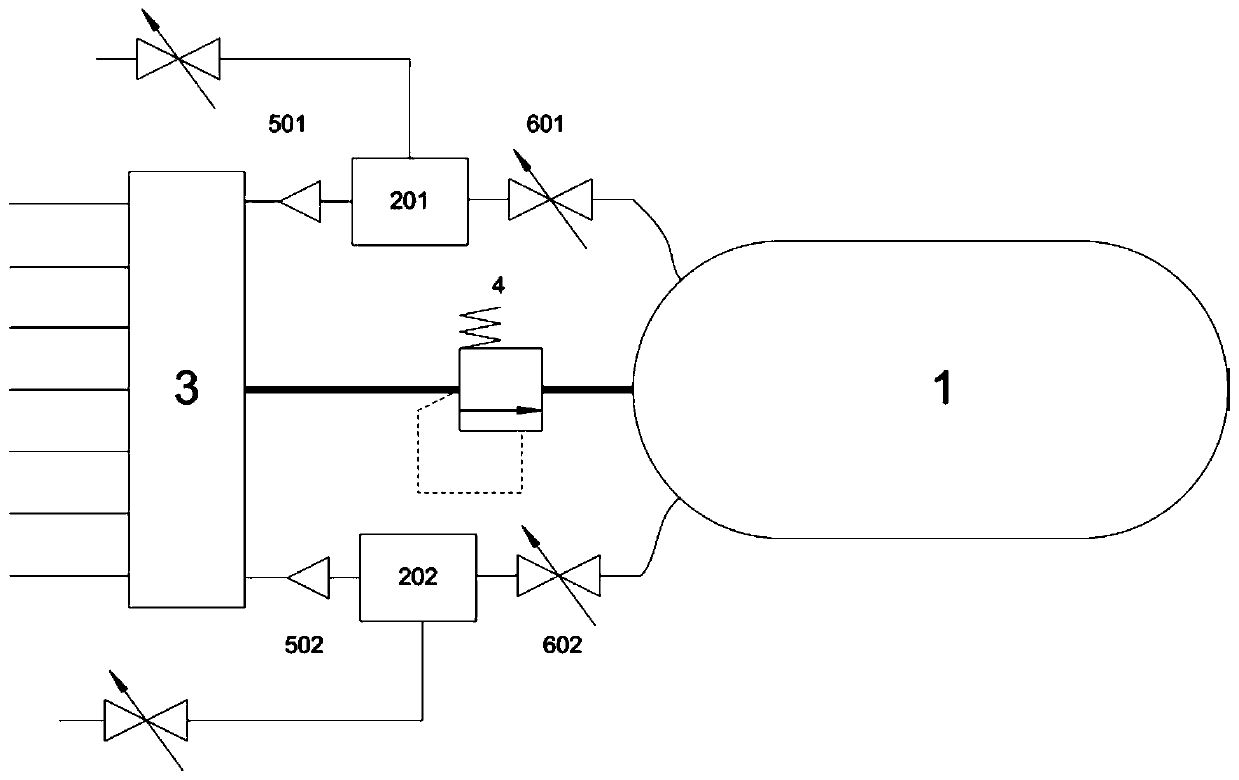

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

[0033] At present, underwater vehicles use solid gunpowder to burn high-temperature gas. Solid gunpowder has a high energy density, which can reduce the space occupied by the vehicle. The design of gas control valve parts and the heat insulation design of equipment have brought great difficulties. Aiming at the disadvantage of high temperature of high-temperature gas, the present invention proposes a method of introducing external water to mix with high-temperature gas to achieve the purpose of reducing the temperature of gas.

[0034] Specifically, the embodiment of the present invention pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com