A side column collision test method and its parameter extraction method

A test method and parameter extraction technology, applied in the field of automobile crash test, can solve the problems of high development cost, lack of simulated deformation, immature technical methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

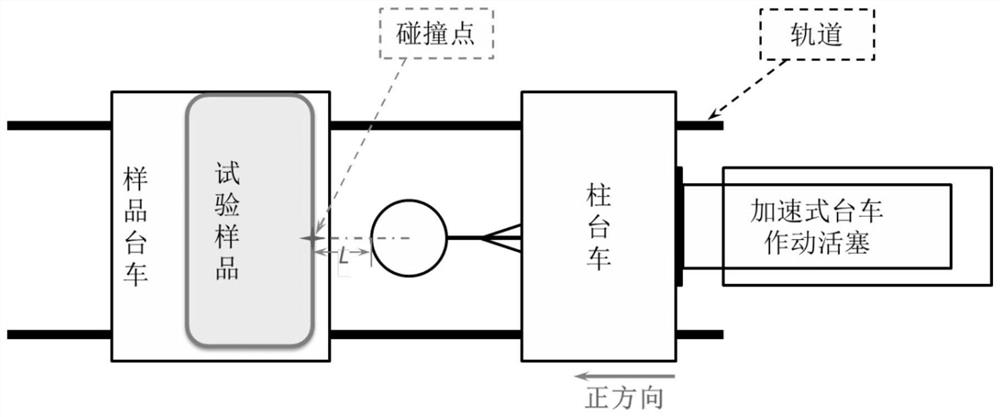

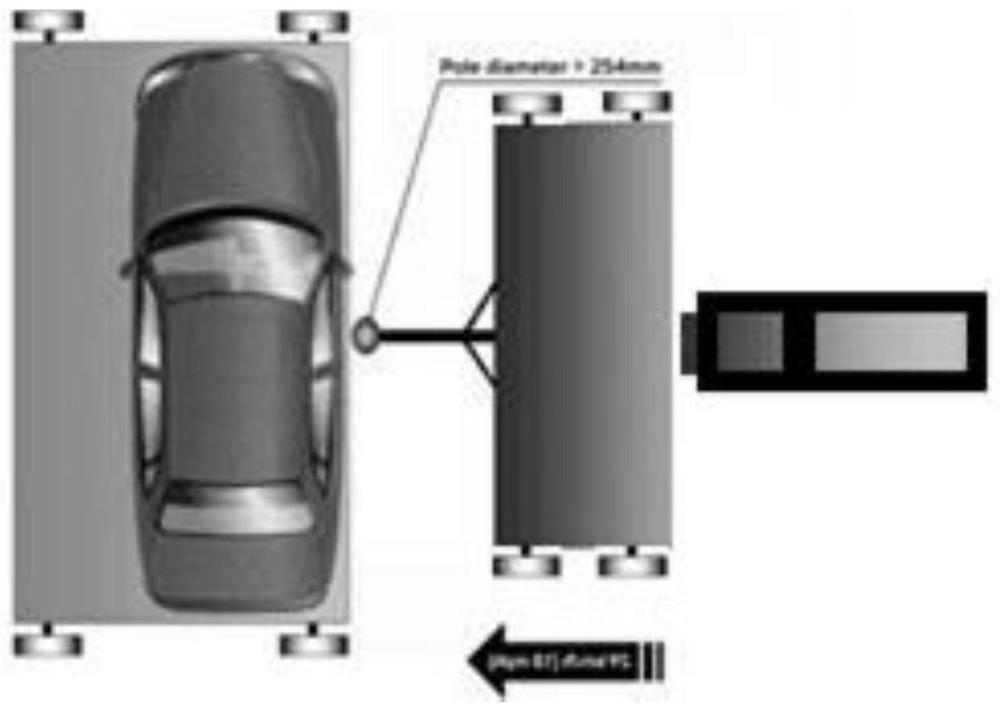

[0121] The test system is divided into two parts, the sample trolley and the column trolley, and the column trolley and the piston actuator of the trolley are fitted (not hinged), such as image 3 shown. The column car is installed with a collision column, and the total mass of the column car is counterweighted to M p . The sample trolley and the column trolley are placed at intervals, and the distance between the end face of the collision column and the test sample is L. The total mass of the sample trolley is counterweighted to M s .

[0122] Use the piston actuator of the trolley to accelerate the column trolley, so that the collision column and the test sample approach and collide. The input function of the acceleration waveform of the piston actuator is Input(t).

[0123] The collision column is in contact with the vehicle body, and a collision process occurs, and the damage value of the collision dummy in the test vehicle body is obtained.

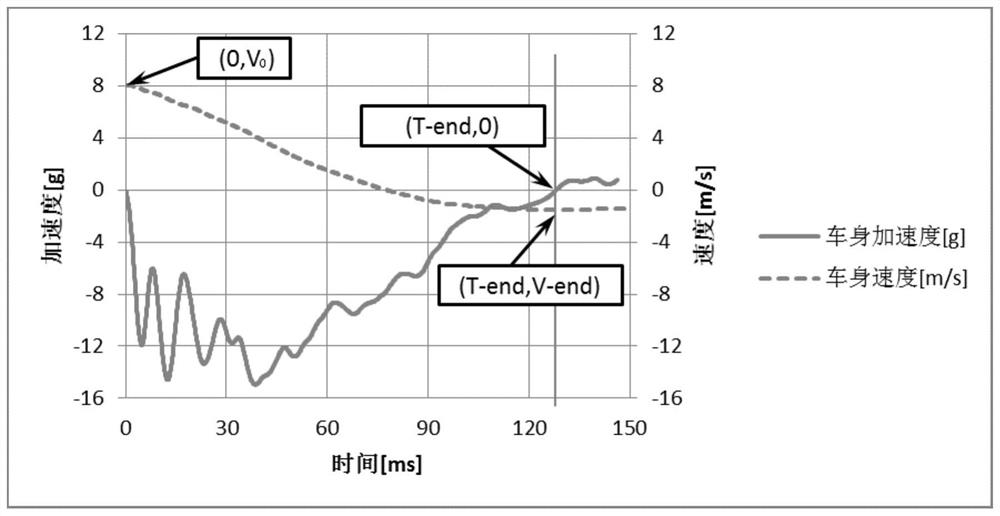

[0124] The method to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com