Test production line

A production line, aging test technology, used in environmental/reliability testing, measuring electricity, measuring devices, etc., can solve the problems of large size of the testing machine, affecting the service life, huge, ranging from a few meters to dozens of meters, etc. Achieve the effect of reducing the operating frequency, prolonging the service life and shortening the moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

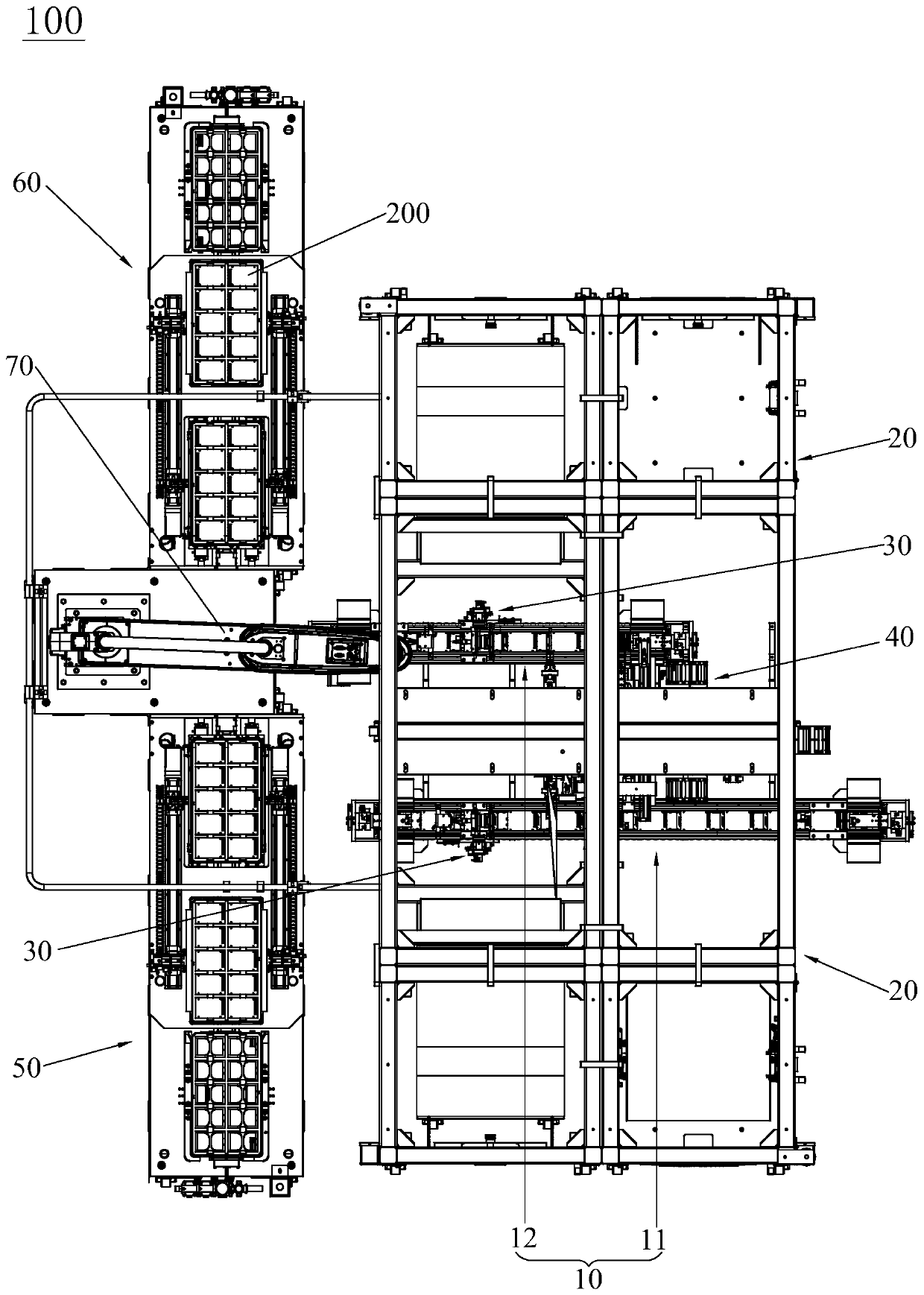

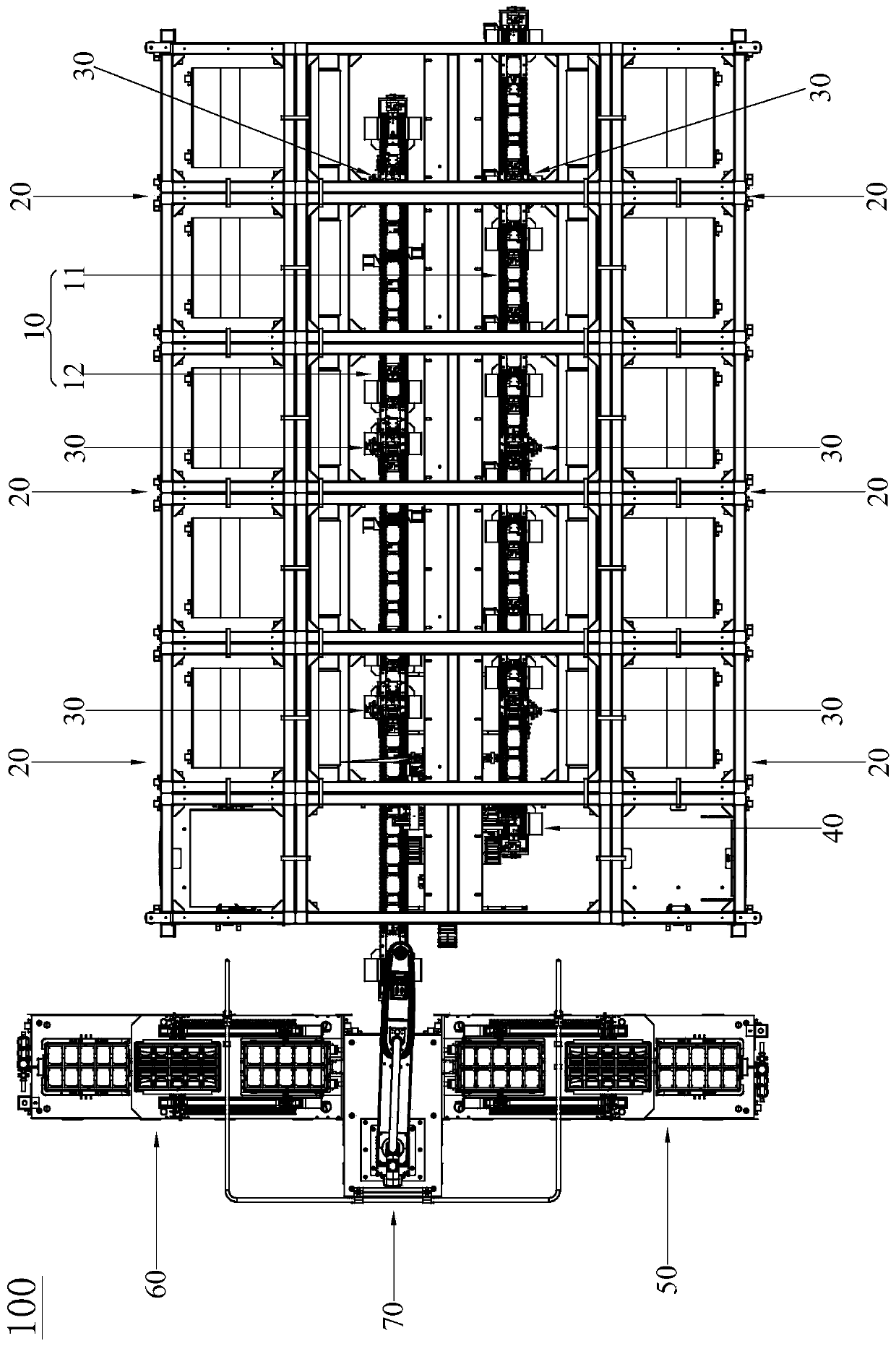

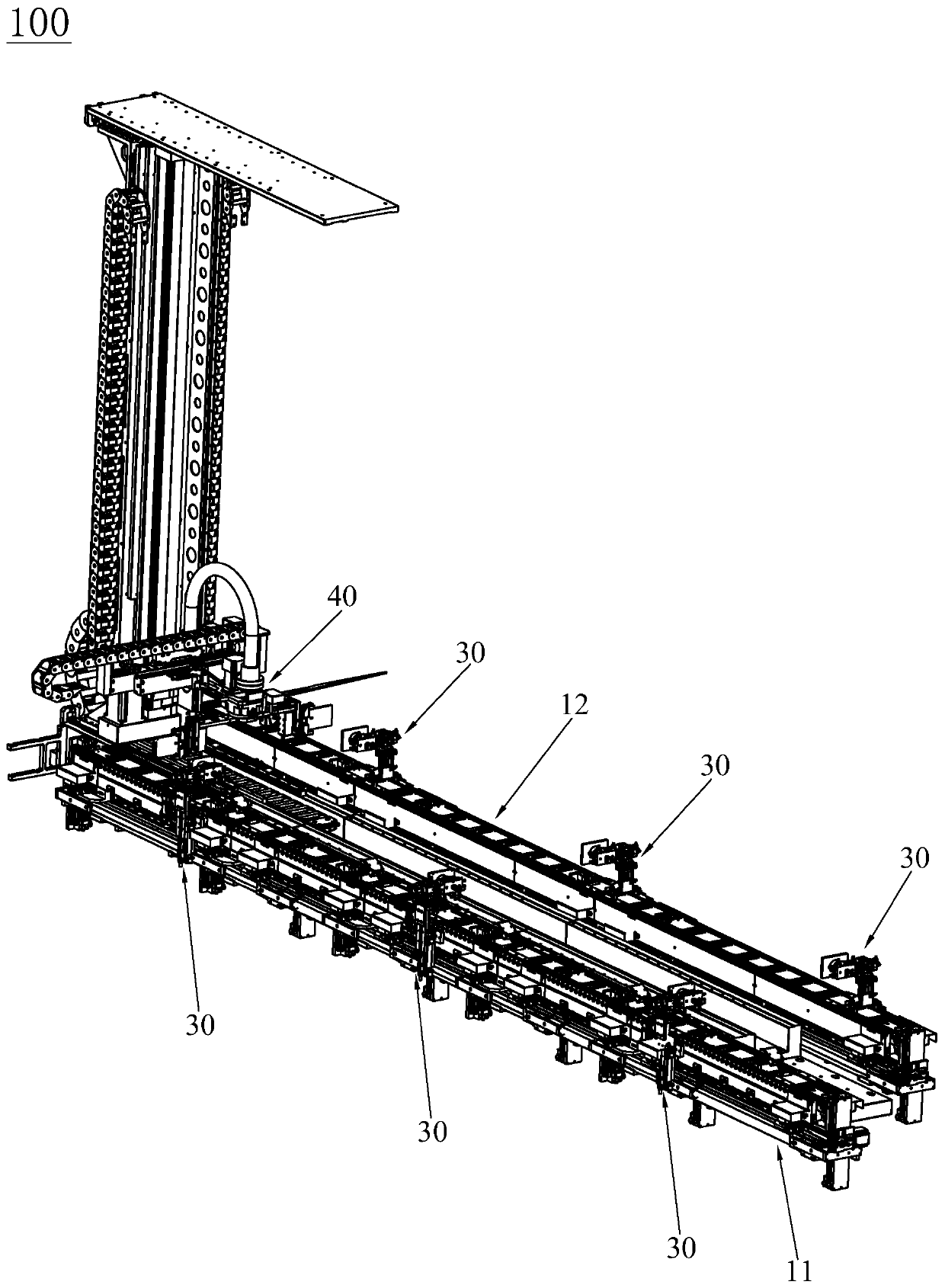

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0025] see Figure 1 to Figure 8 , the present invention discloses a test production line 100, which is suitable for aging testing of electronic products such as lithium batteries, semiconductors, and solid-state hard disks. The structure and working principle of the test production line 100 of the present invention will be described below by taking the solid-state hard disk 200 as an example. The test production line 100 of the present invention includes a transmission device 10, a detection device 20, an adapter device 30 and a plug-in device 40. The transmission device 10 transmits the solid-state hard disk 200 in a horizontal arrangement; the detection device 20 is used for aging the solid-state hard disk 200. The test is specifically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com