Modularization method for building design, manufacturing and construction

A technology of architectural design and modularization, applied in computing, special data processing applications, instruments, etc., can solve the problems of low efficiency and high cost, lack of modularization, standardization, generalization and informatization, and achieve the goal of reducing overall cost and process The effects of generalization, simplification and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

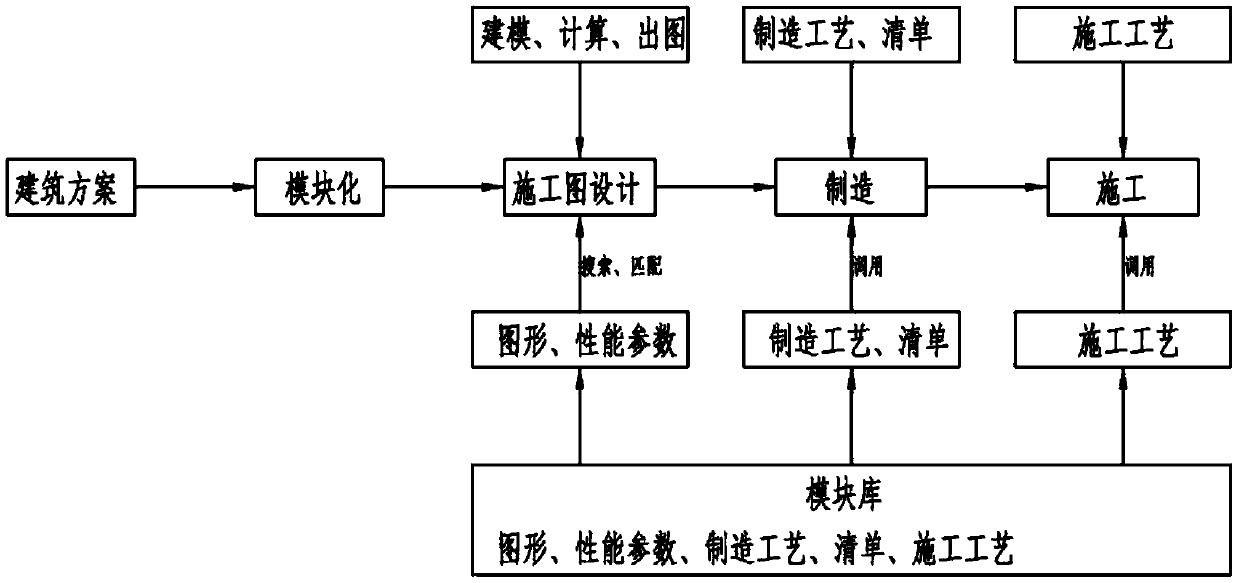

[0031] Embodiment 1, a modular method of architectural design, manufacture and construction of the present invention, comprising:

[0032] (1) Divide the building into different standard modules; such as: prefabricated exterior wall standard modules, internal shear wall standard modules, partition wall standard modules, beam standard modules, floor standard modules, staircase standard modules, air conditioning board standard modules, stairs Rest platform slab standard module and column standard module;

[0033] (2) Corresponding to each standard module, the designer models, calculates, and draws, so that each standard module contains all information such as complete graphics, lists, performance parameters, manufacturing processes, and construction processes;

[0034] (3) Use the big data platform to build a standardized module library shared by the whole industry;

[0035] (4) Import the standard module information of the above (1), (2) into the module library of (3);

[003...

Embodiment 2

[0039] Embodiment 2, another modular method of architectural design, manufacture and construction of the present invention, including:

[0040] (1) Divide the building into different standard modules; such as prefabricated exterior wall standard modules, internal shear wall standard modules, partition wall standard modules, beam standard modules, floor slab standard modules, staircase standard modules, air-conditioning board standard modules, and stair rests Platform plate standard modules and column standard modules.

[0041] (2) Corresponding to each standard module, the designer models, calculates, and draws, so that each standard module contains all information such as complete graphics, lists, performance parameters, manufacturing processes, and construction processes;

[0042] (3) Use the big data platform to build a standardized module library shared by the whole industry;

[0043] (4) Import the standard module information of the above (1), (2) into the module library...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com