Large-current pin structure of vertical resonant transformer

A resonant transformer, high current technology, applied in the direction of transformer/inductor shell, transformer/inductor core, transformer/inductor components, etc., can solve complex structure, shortened safety distance, and limited winding area question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

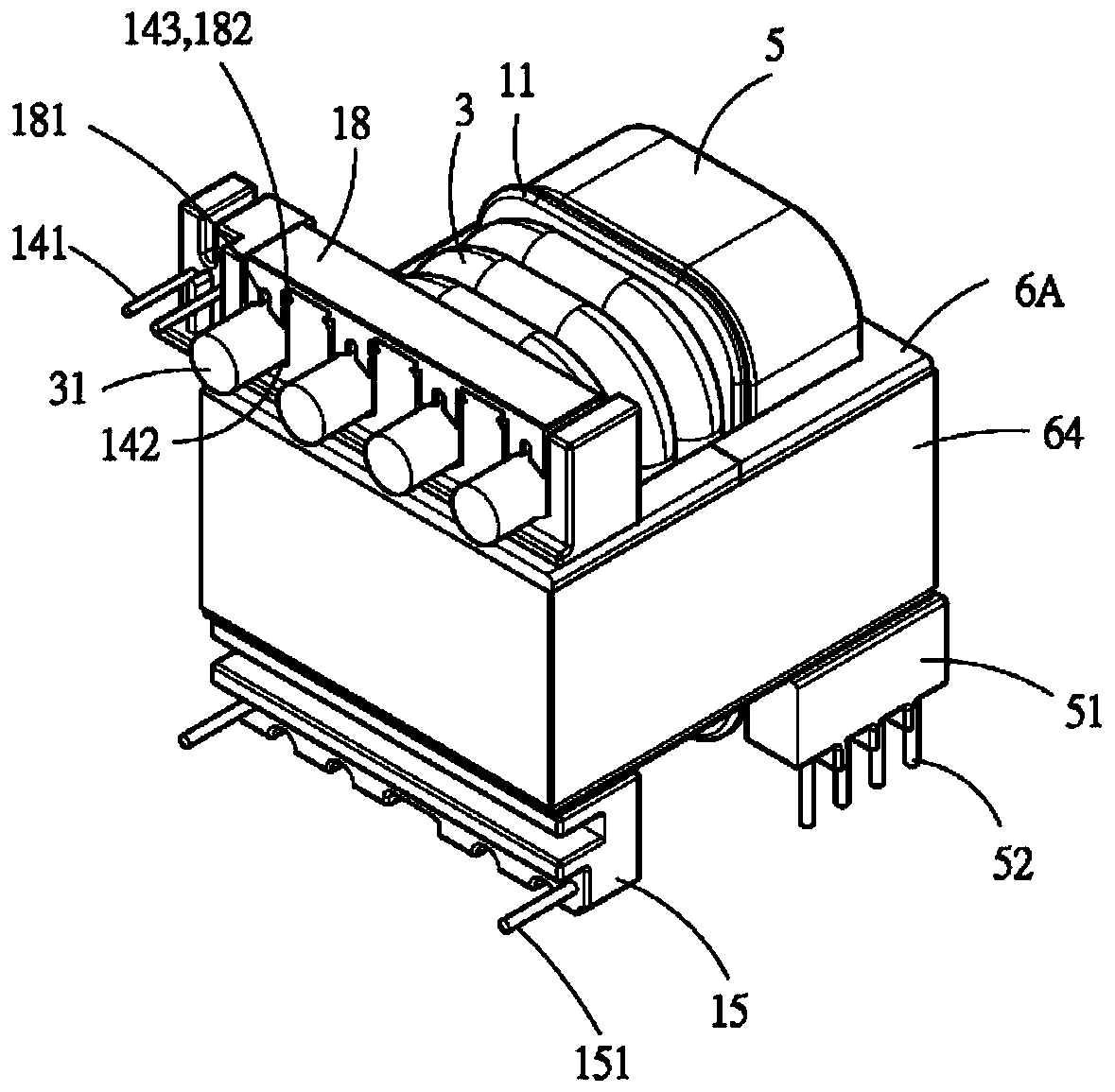

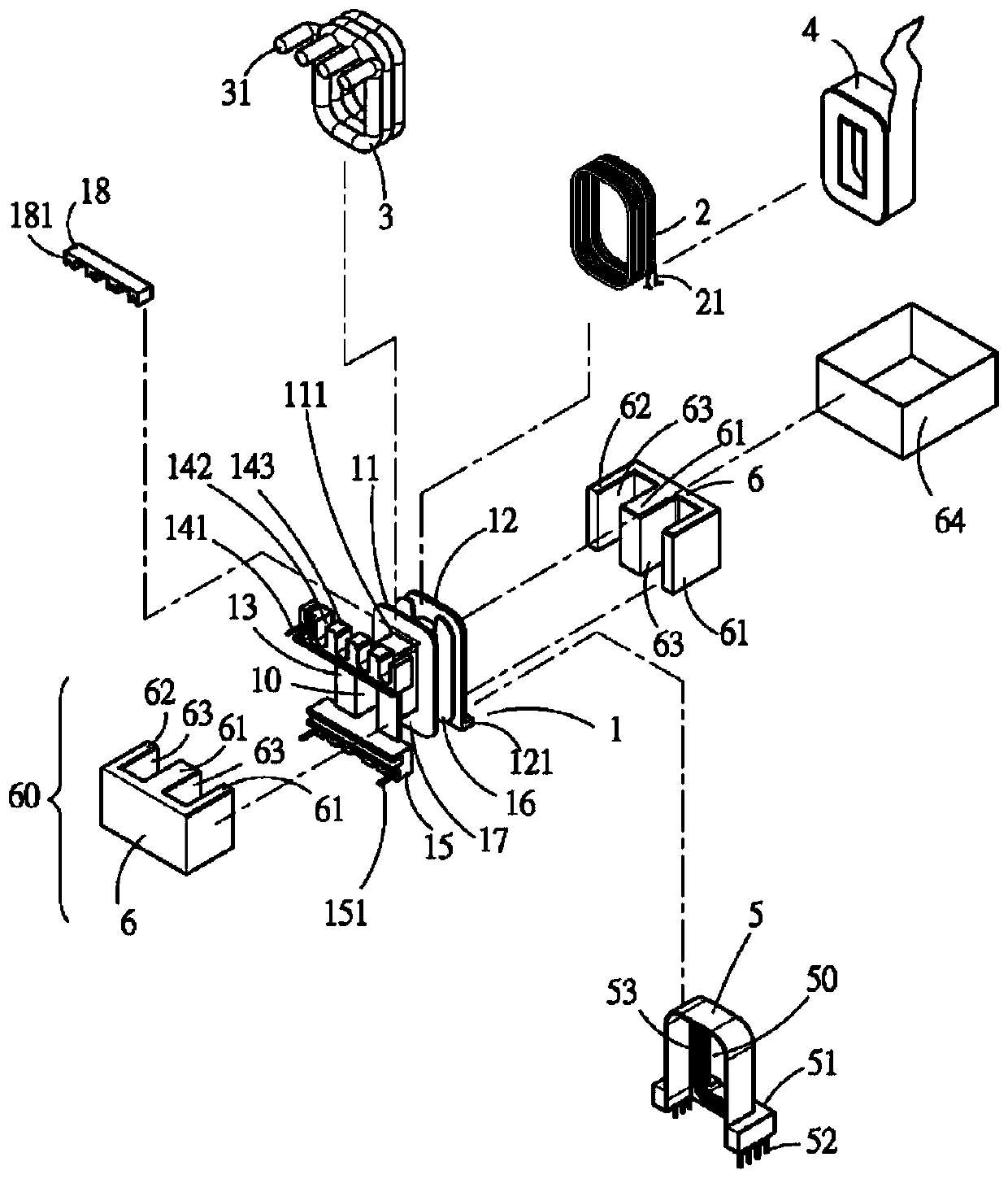

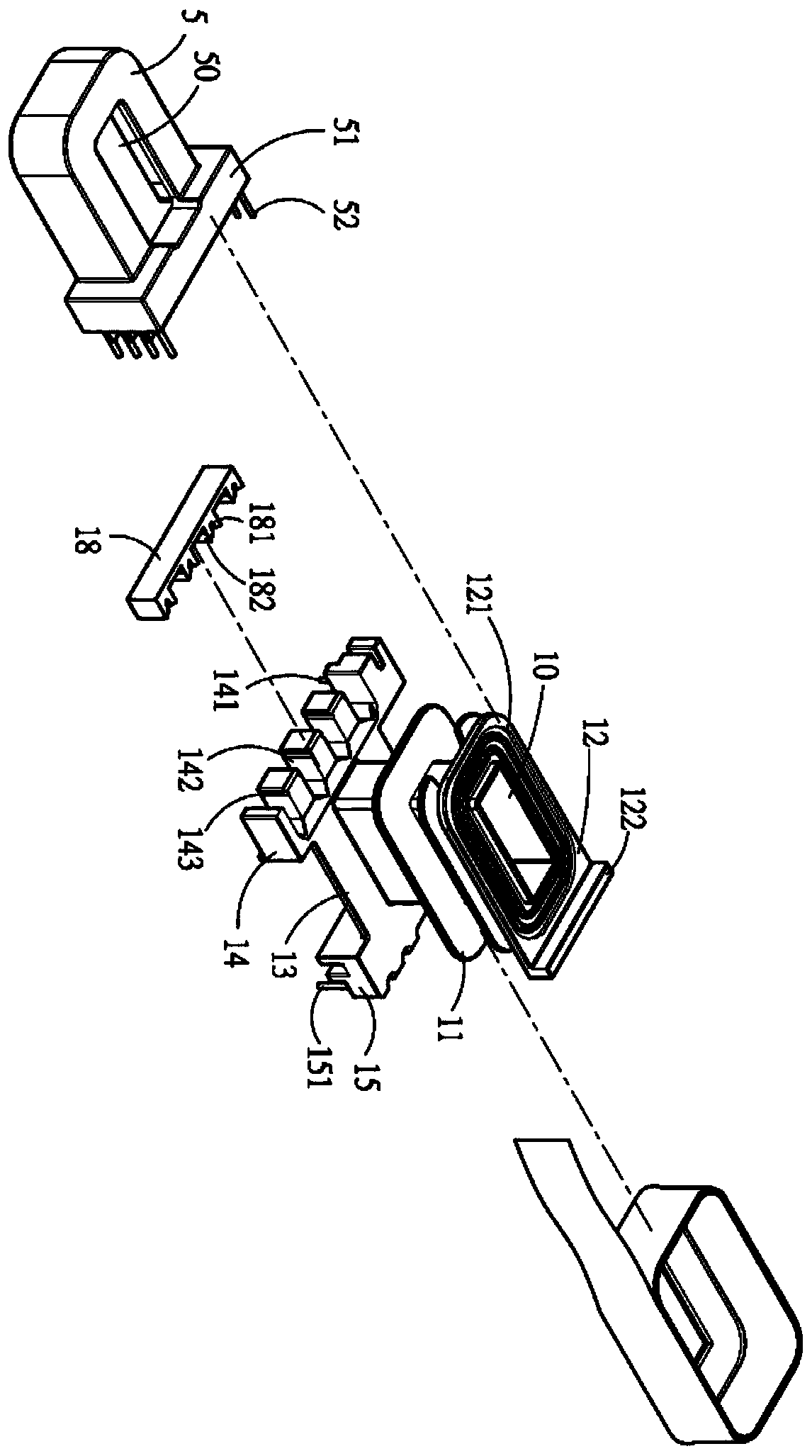

[0032] see Figure 1 to Figure 3 As shown, it can be seen that the structure of the present invention mainly includes: a frame 1, a first coil 2, a second coil 3, an insulating layer 4, a shell 5 and a core group 6, wherein:

[0033] There is a central hole 10 in the wire frame 1, a first partition plate 11 is arranged on the wire frame 11, a second partition plate 12 and a third partition plate 13 are respectively arranged at both ends, and the second partition plate The surface of 12 is provided with a plurality of first ring parts 121; the third partition plate 13 has a connection part 14 on one side, and a plurality of control pins 141 are provided on the connection part 14 side, and a plurality of control pins 141 are provided on the connection part 14. The grooves 142, these grooves 142 have a joint portion 143 near the opening, these grooves 142 are used for a fixed block 18 to be assembled, and the fixed block 18 extends with a large number of positioning pins 181, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com