Removing components of alcoholic solutions via forward osmosis and related systems

A forward osmosis and reverse osmosis technology, used in semi-permeable membrane separation, beer brewing, alcoholic beverage preparation, etc., can solve problems such as unfavorable alcohol solution concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

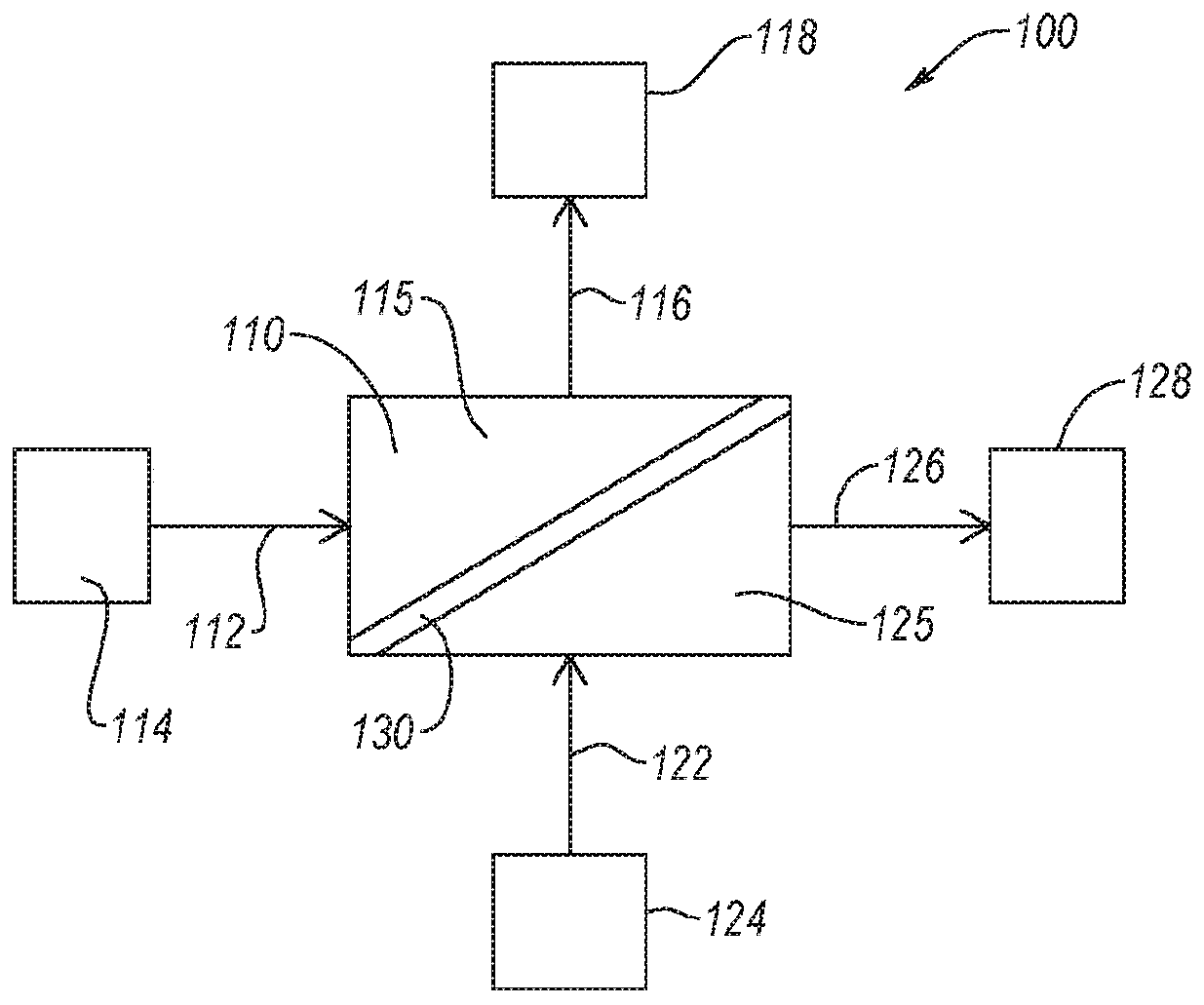

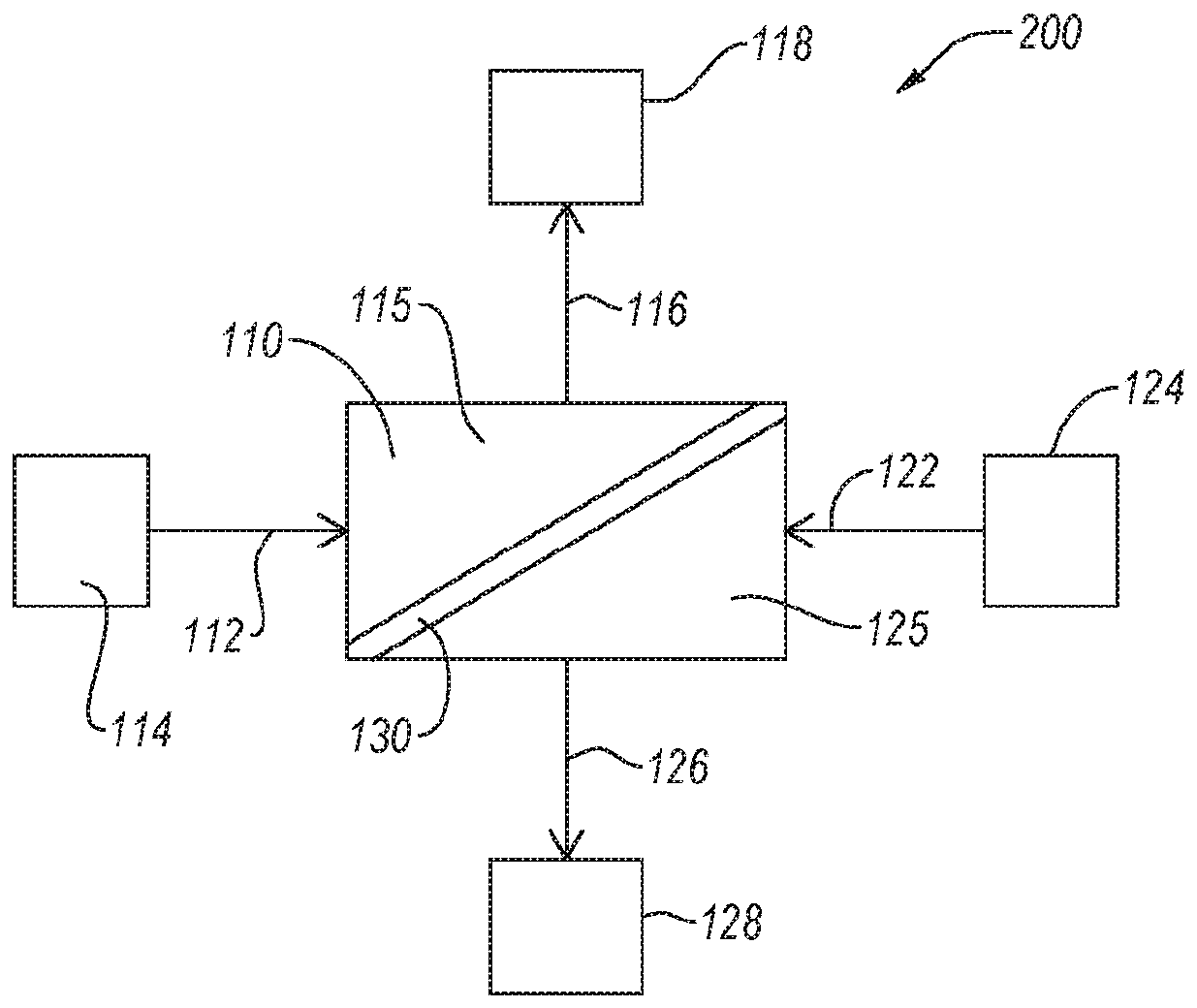

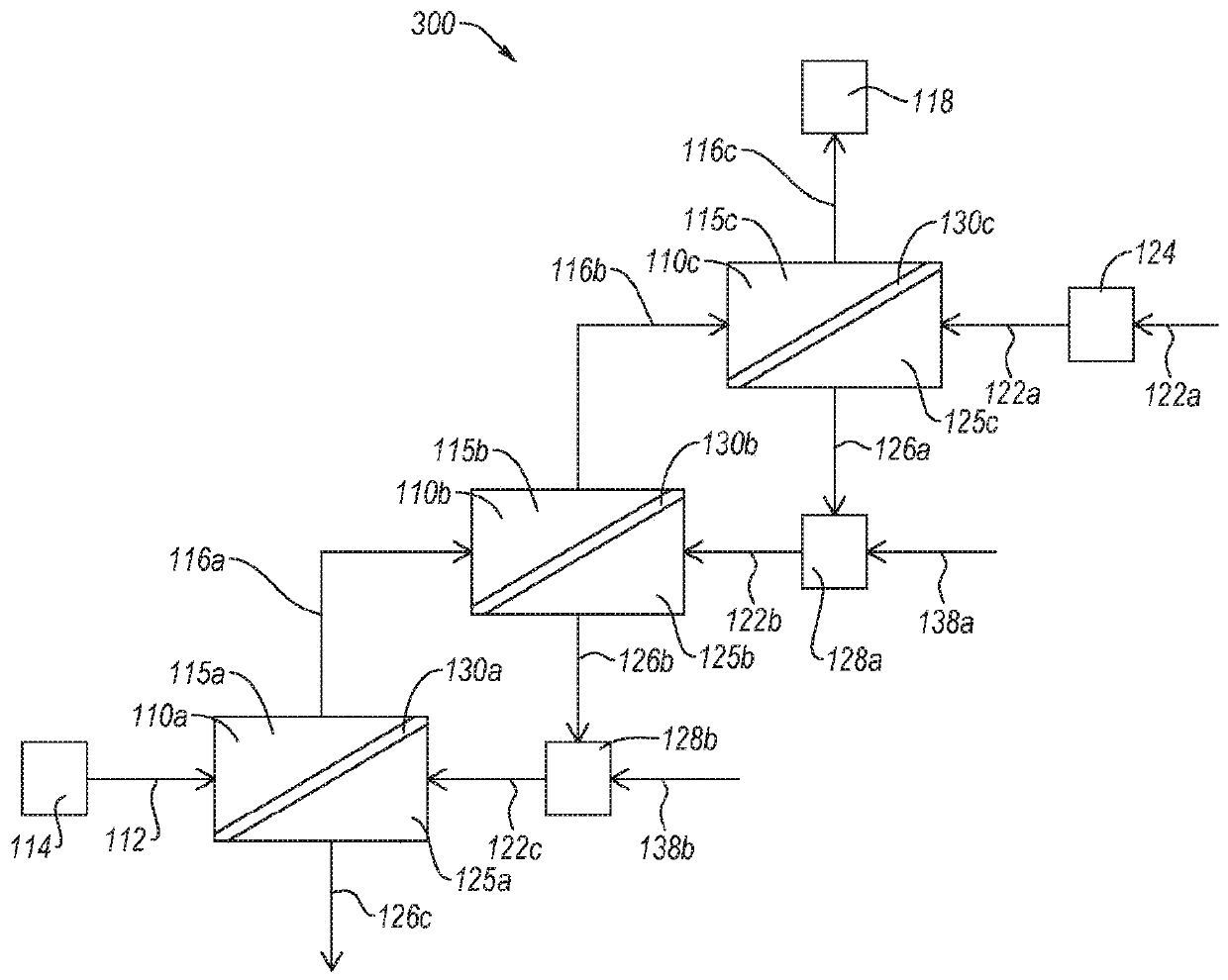

[0033] Embodiments described herein relate to methods and systems thereof for removing water or water and a permeable solute from a solution having one or more permeable solutes therein using forward osmosis (FO). FO can be used to selectively separate one or more solutes (eg, dissolved, dispersed, or suspended components of a solvent system) from one or more solvents. The one or more solutes may comprise at least partially dissolved, dispersed or suspended one or more sugars, one or more alcohols, volatile organic compounds (VOCs), proteins, one or more salts, one or more sugars Alcohols or other components of a liquid system capable of being filtered (eg, retained or removed) by FO at a filter membrane and combinations of any of the preceding components thereof. The solutes may include permeable solutes that are able to pass through the FO membrane, such as ethanol, methanol, ethylene glycol, and the like. Solutes may include impermeable solutes that are substantially unabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com