Watch band disassembling raw grain assembling mold and method

A technology for assembling molds and watch straps, which is used in handheld tools, manufacturing tools, etc., to achieve the effects of easy production, uniform assembly specifications, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

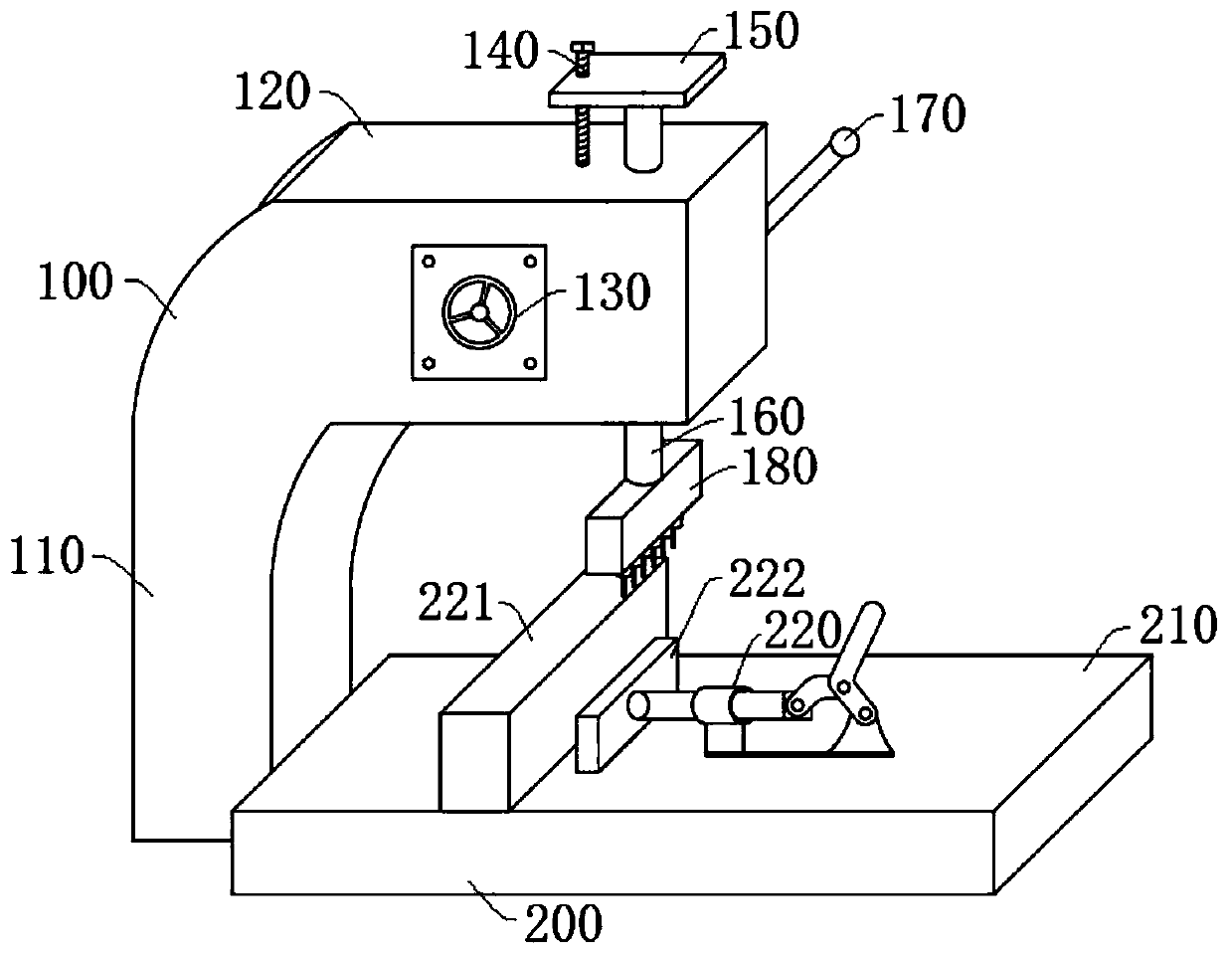

[0049] Such as Figure 3-5 As shown, a mold for dismantling and assembling watchbands includes an upper mold module 100 and a lower mold module 200. The upper mold module 100 and the lower mold module 200 are combined to form a whole mold. The combined use of the upper mold and the lower mold overcomes the problems of low quality and low efficiency in the watchband dismantling and assembling industry. The upper mold and the lower mold are combined into a whole through the column 110. The combination of the upper mold and the lower mold can effectively meet the needs of the movement and rectification of the equipment in the factory, save time and effort, and facilitate production. The lower mold mainly fixes the raw grains of the strap, providing a working environment for the completion of the assembly. , The upper mold completes the assembly of the raw grain of the strap. Compared with manual assembly, it saves time and effort, has high precision, and uniform assembly specific...

Embodiment 2

[0056] On the basis of embodiment 1, this embodiment combines figure 1 with figure 2 A method for dismantling and assembling a watch strap is provided, comprising the following steps:

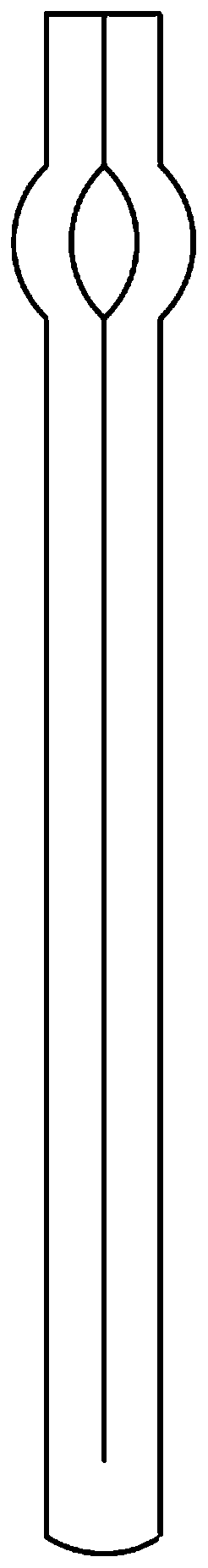

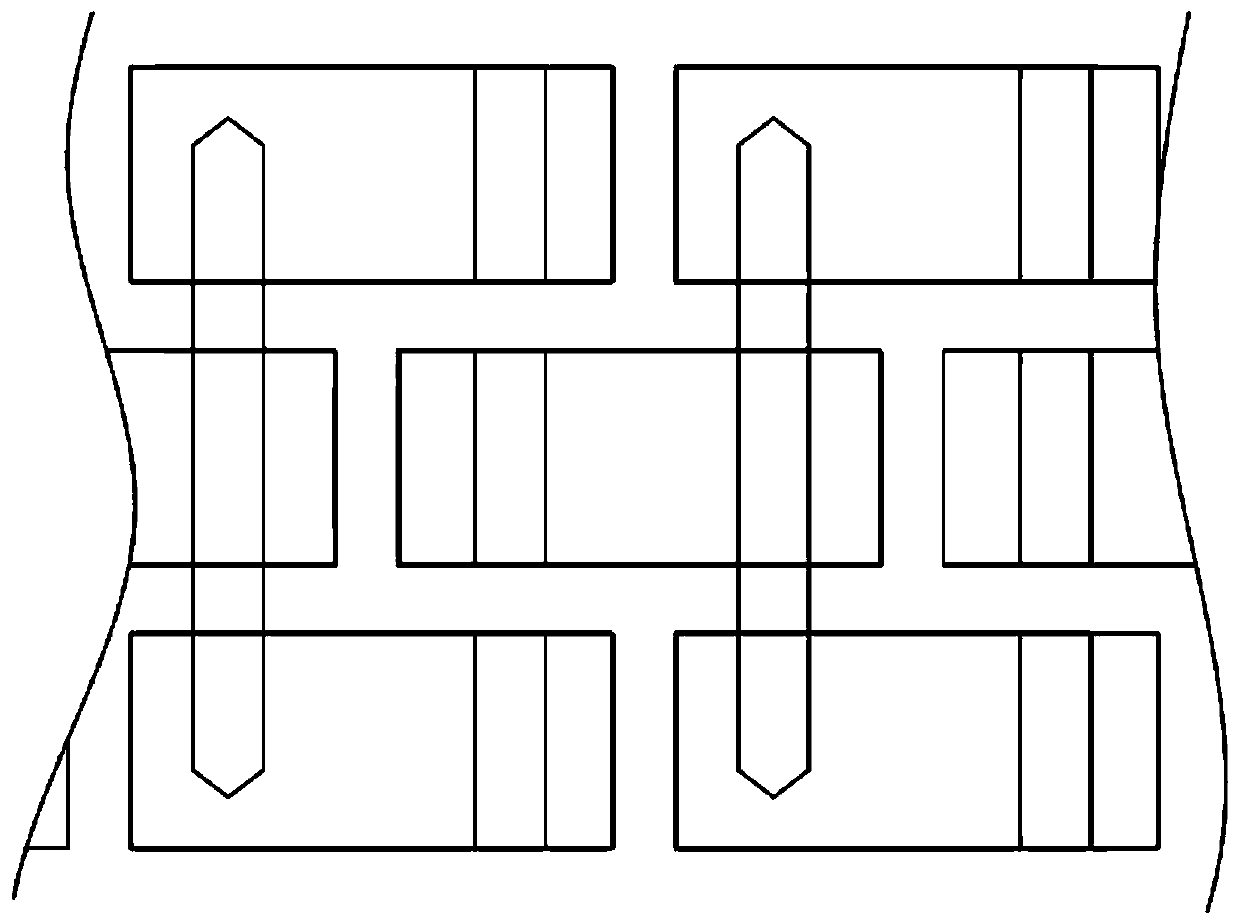

[0057] S1. Disassemble the three-bead strap according to the figure 2 As shown in the combination, thread the connecting piece at the blind hole where the raw grain is removed on both sides, and thread it at the through hole figure 1 As for the hair clip shown, when the hair clip is inserted, the protruding end is located at the top of the raw grain of the strap.

[0058] S2. Put the combination formed by dismantling raw grains and hairpins of the watchband against the vertical working surface of the backing plate 221 vertically, and fix the combination formed by dismantling the raw grains and hairpins using the fixing clip on the lower die base 210, so that it does not move relative to each other.

[0059] S3. Record the initial height of the bottom end of the press-fit part 182 as D, D=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com