A production process for removing impurities from waste fibers

A production process and fiber technology, which is applied in the field of impurity removal production process, can solve the problems of reduced quality of composite fibers, difficulty in removing impurities completely, and insertion of silk threads into impurities, etc., to achieve safe and convenient use, convenient collection and cleaning, and easy infiltration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

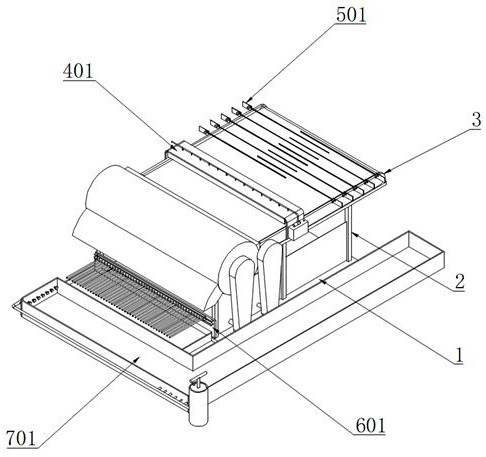

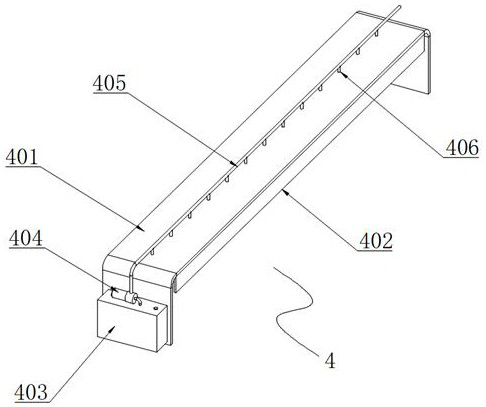

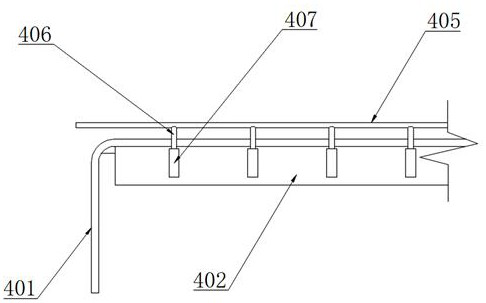

[0044] Embodiment 1: as Figure 1-7 As shown, the present invention provides a technical solution, a production process for removing impurities in waste fibers, comprising an opener base plate 1, an opener frame 2 is installed on the top of the opener base plate 1, an opener machine An opener transmission frame 3 is installed on the top of the frame 2, and a filter assembly 6 is installed on the bottom of the opener frame 2. The filter assembly 6 includes a second mounting plate 601, a limit frame 602, a convex bar 603, a support column 604, and a second mounting plate 601. Second motor 605, second swing rod 606, connecting rod 607 and connecting seat 608;

[0045]A second mounting plate 601 is embedded on one side surface of the bottom of the frame 2 of the opener, and two limiting frames 602 are installed on the top of one side of the second mounting plate 601, and a convex joint is slidingly connected between the two limiting frames 602. Bar 603, one end of the convex bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com