DA-SVM-based rolling bearing fault detection method

A DA-SVM and rolling bearing technology, which is applied in the direction of instruments, character and pattern recognition, calculation models, etc., can solve the problems of low detection speed and detection accuracy, and achieve high fault detection accuracy, strong optimization ability, and detection speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

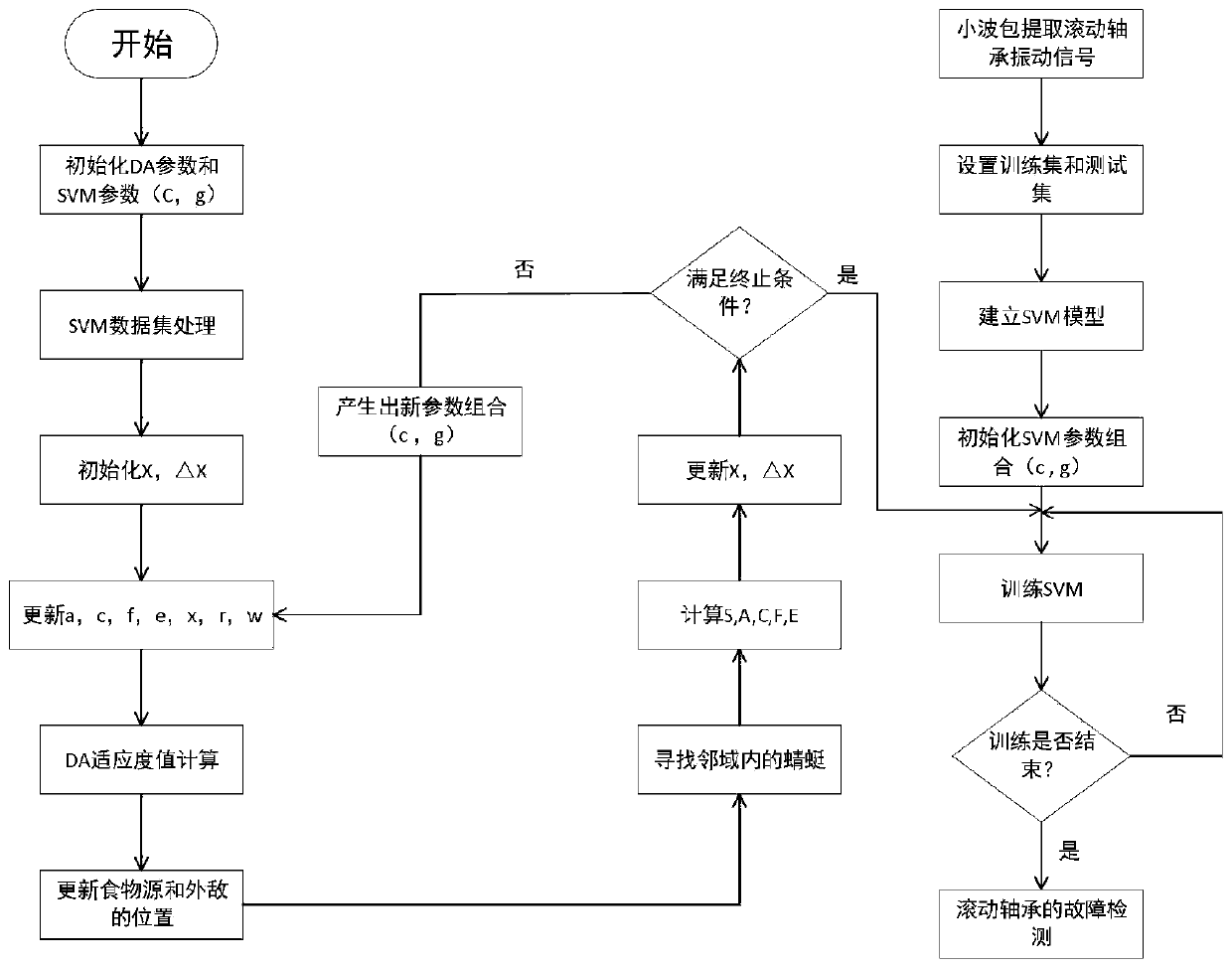

[0053] Example 1: Such as Figure 1-7 As shown, a DA-SVM-based rolling bearing fault detection method includes the following steps:

[0054] Step 1. The acceleration sensor synchronously acquires the signal generated by the rolling bearing rotation, and then decomposes and reconstructs the acquired original signal by wavelet packet, and extracts the energy eigenvalues of the 8 nodes in the third layer, which is used as the eigenvector. As shown in Table 1, it lists some sample energy characteristic values of four types of signals: normal state of rolling bearing, rolling element failure, outer ring failure, and inner ring failure. among them. The serial numbers 1-5 indicate the sample energy characteristic values under normal conditions, the serial numbers 6-10 indicate the sample energy characteristic values of shaft failure, the serial numbers 11-15 indicate the sample energy characteristic values of the outer ring failure; the serial numbers 16-20 indicate the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com