Liquid crystal display device

A technology of liquid crystal display devices and liquid crystal compositions, applied in liquid crystal materials, porphine/acridine porphine, optics, etc., can solve problems such as uneven orientation, increased ion density of voltage retention rate, and white spots, so as to prevent white spots and Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

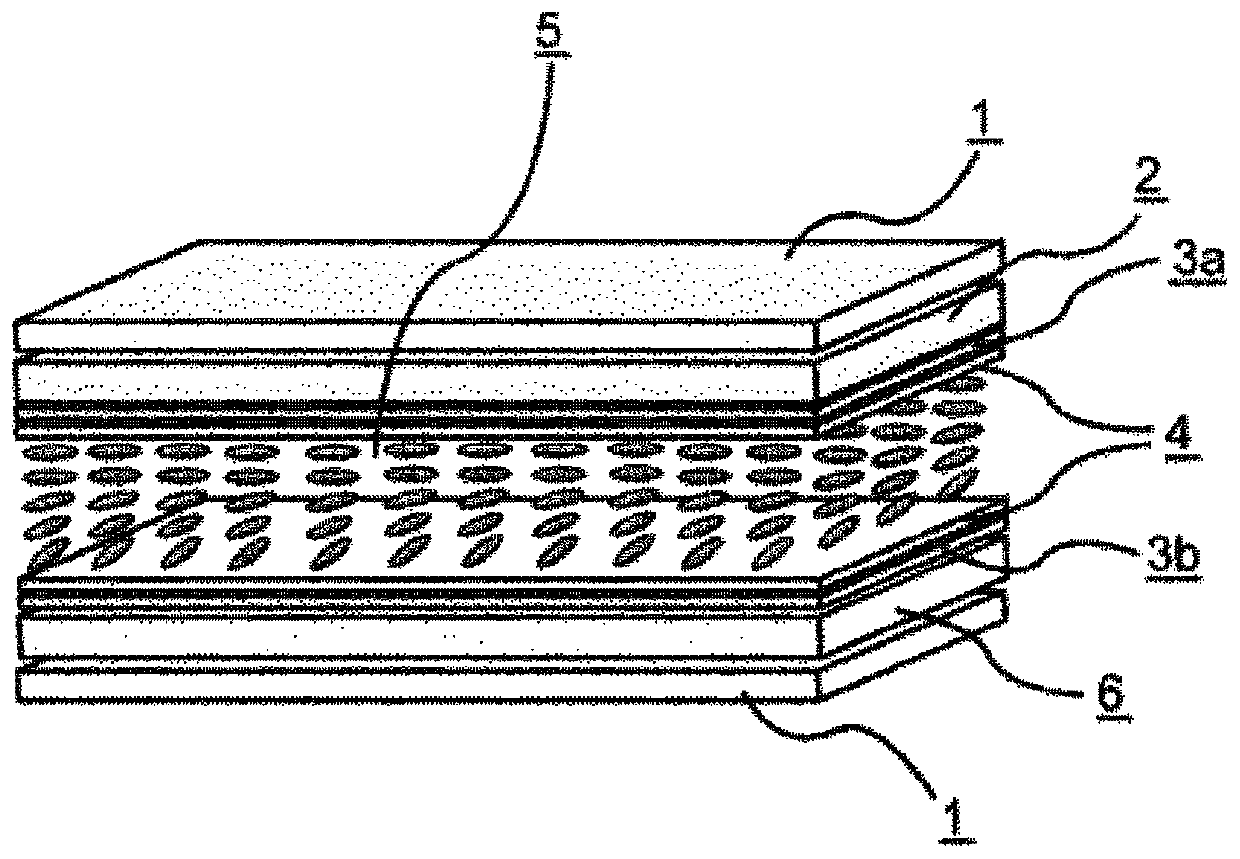

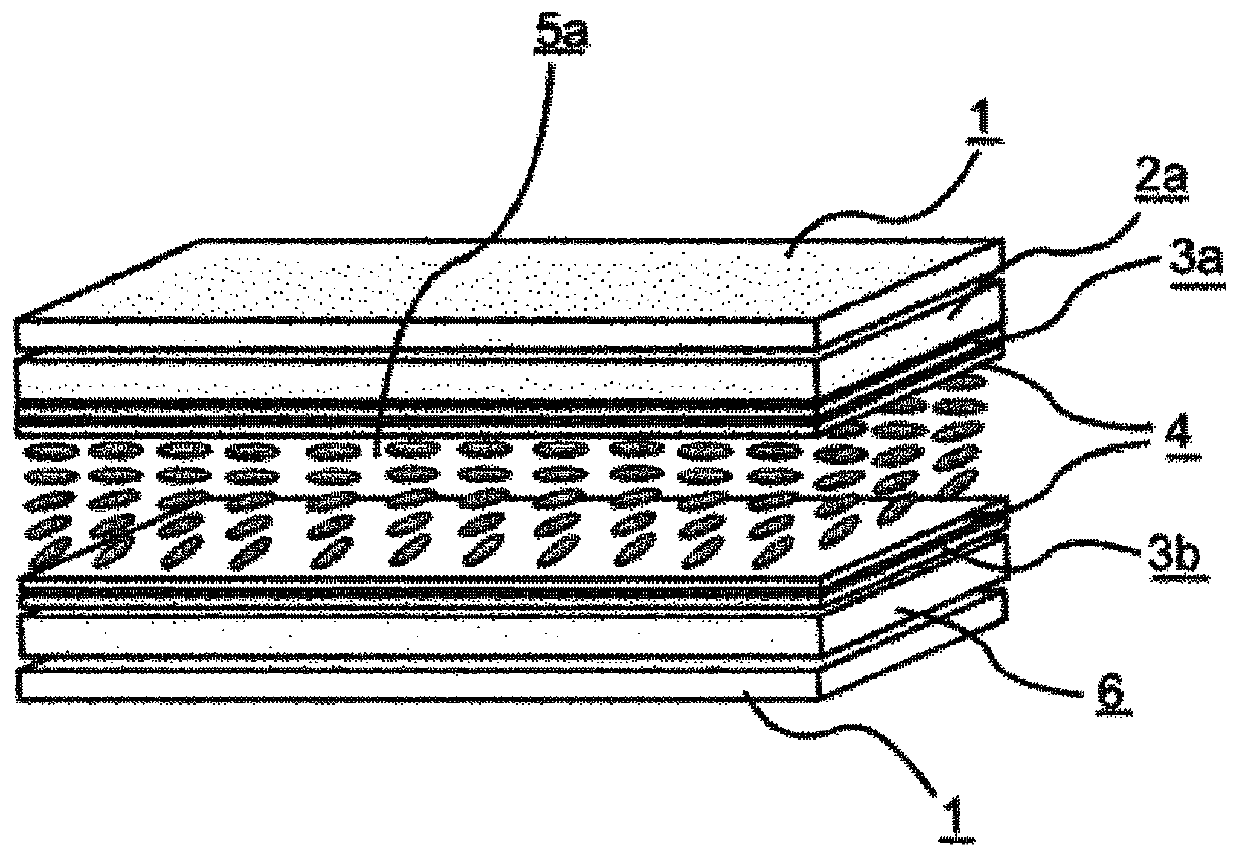

[0410]Fabricate an electrode structure on at least one of the first and second substrates, perform a weak rubbing treatment after forming a horizontally oriented alignment film on the respective opposite sides, and fabricate an IPS unit, sandwiching between the first substrate and the second substrate Liquid crystal composition 1 shown below was used. The physical property values of the liquid crystal composition 1 are shown in the following table. Next, using the color filters 1 to 5 shown in the above table, the liquid crystal display devices of Examples 1 to 5 were fabricated (d gap =4.0 μm, alignment film AL-1051). The VHR of the obtained liquid crystal display device was measured. In addition, burn-in evaluation was performed on the obtained liquid crystal display device. The results are shown in the following tables.

[0411] [Table 11]

[0412] Liquid crystal composition 1

[0413]

[0414] [Table 12]

[0415] Example 1 Example 2 Example 3 ...

Embodiment 6~15

[0419] In the same manner as in Example 1, liquid crystal display devices of Examples 6 to 15 were produced by sandwiching liquid crystal compositions 2 to 3 shown in the following table, and using color filters 1 to 5 shown in the above table, and their VHRs were measured. In addition, this liquid crystal display device was evaluated for burn-in. The results are shown in the following tables.

[0420] [Table 13]

[0421]

[0422] [Table 14]

[0423] Example 6 Example 7 Example 8 Example 9 Example 10 liquid crystal composition Liquid crystal composition 2 Liquid crystal composition 2 Liquid crystal composition 2 Liquid crystal composition 2 Liquid crystal composition 2 color filter color filter 1 color filter 2 color filter 3 color filter 4 color filter 5 VHR 99.4 99.5 99.6 99.5 99.5 burn screen ○ ○ ◎ ◎ ◎

[0424] [Table 15]

[0425] Example 11 Example 12 Example 13 Example 14 E...

Embodiment 16~30

[0428] Liquid crystal display devices of Examples 16 to 30 were produced by sandwiching liquid crystal compositions 4 to 6 shown in the following table in the same manner as in Example 1, and their VHRs were measured using color filters 1 to 5 shown in the above table. In addition, this liquid crystal display device was evaluated for burn-in. The results are shown in the following tables.

[0429] [Table 16]

[0430]

[0431] [Table 17]

[0432] Example 16 Example 17 Example 18 Example 19 Example 20 liquid crystal composition Liquid crystal composition 4 Liquid crystal composition 4 Liquid crystal composition 4 Liquid crystal composition 4 Liquid crystal composition 4 color filter color filter 1 color filter 2 color filter 3 color filter 4 color filter 5 VHR 99.4 99.4 99.6 99.6 99.5 burn screen ○ ○ ◎ ◎ ○

[0433] [Table 18]

[0434] Example 21 Example 22 Example 23 Example 24 Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com